Supporting and heat insulation integrated heat preservation cylinder and preparation method thereof

A heat preservation cylinder and cylinder body technology, applied in chemical instruments and methods, crystal growth, self-melting liquid pulling method, etc., can solve the problem of affecting the thermal insulation effect of the heat preservation cover, inconvenient installation and disassembly of the heat preservation cover, and adding graphite carbon felt Difficulty in wrapping and other issues, to achieve good heat insulation effect, shorten installation time, and save consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] An embodiment of the present invention provides an integrated thermal insulation barrel with support and heat insulation. The heat preservation barrel includes a matching inner cylinder body and an outer layer cylinder body.

[0038] The density of the outer cylinder is less than that of the inner cylinder. Specifically, the density range of the inner cylinder is 1.1~16.6 g / cm 3 , the density range of the outer cylinder is 0.12~0.22 g / cm 3 .

[0039] The outer surface of the inner cylinder is connected with the inner surface of the inner cylinder through pyrolytic carbon to form an integrated thermal insulation cylinder. The structure of the insulation cylinder is stable, the cracking is not easy to occur during use, and the service life is long.

[0040] The inner cylinder of the heat preservation cylinder includes carbon fiber mesh tires and carbon fiber cloth that are alternately laid and wound, and the inner cylinder adopts a surface density of 40~200 g / cm 2 car...

Embodiment 2

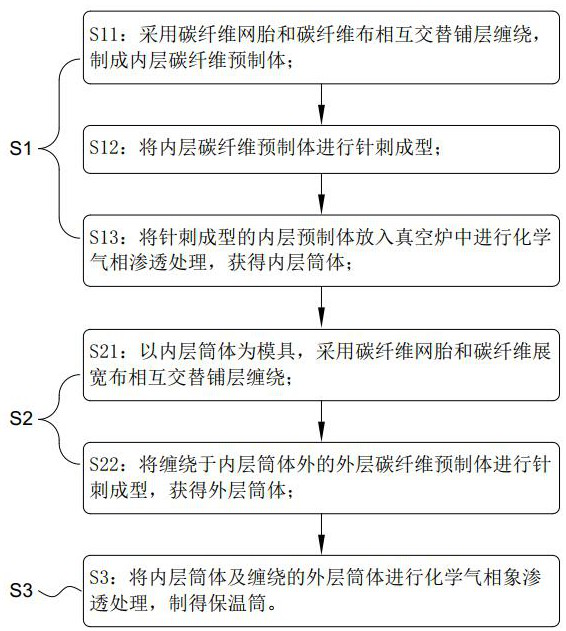

[0045] refer to figure 1 , the present embodiment provides a method for preparing a support and heat insulation integrated heat preservation cylinder, which is suitable for preparing the heat preservation cylinder described in Example 1, and the preparation method includes the following steps:

[0046] S1 preparation of the inner cylinder:

[0047] S11 uses an areal density of 40 g / cm 2 The carbon fiber mesh tire and area density is 100 g / cm 2 After the carbon fiber spread cloth is laid alternately, the mold is wound; the number of layer units is 4, and the gradient of the starting position between each layer is 4cm;

[0048]In S12, the inner layer carbon fiber prefabricated body obtained after layer laying and winding in S11 is needle-punched to form a density of 0.35 g / cm 3 The inner prefabricated body;

[0049] S13 Put the inner layer preform obtained in S12 into a vacuum furnace for chemical vapor infiltration treatment, and obtain a density of 1.1 g / cm 3 the inner cy...

Embodiment 3

[0056] This embodiment provides a method for preparing a support and heat insulation integrated heat preservation cylinder, which is suitable for preparing the heat preservation cylinder described in Example 1. The preparation method includes the following steps:

[0057] S1 preparation of the inner cylinder:

[0058] S11 uses an areal density of 100 g / cm 2 carbon fiber mesh and areal density of 300 g / cm 2 The unidirectional carbon fiber spread cloth is alternately laminated with mesh tires, 0° unidirectional fabrics or mesh tires, and 90° unidirectional fabrics, and then wraps the mold; the number of layered units is 4, and the starting position between each layer Gradient decreasing distance is 2cm;

[0059] In S12, the inner layer carbon fiber prefabricated body obtained after layer laying and winding in S11 is needle-punched to form a density of 0.60 g / cm 3 The inner prefabricated body;

[0060] S13 Put the inner layer preform obtained in S12 into a vacuum furnace for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com