A kind of spiral ribs cold -type cold flame gas burner

A gas burner and spiral ring technology, applied in the direction of gas fuel burners, burners, burners, etc., can solve the problems of high cost, unsuitable for high-pressure and supercritical boilers, and poor effect, so as to reduce the combustion temperature and ensure Heat exchange efficiency and combustion safety, the effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

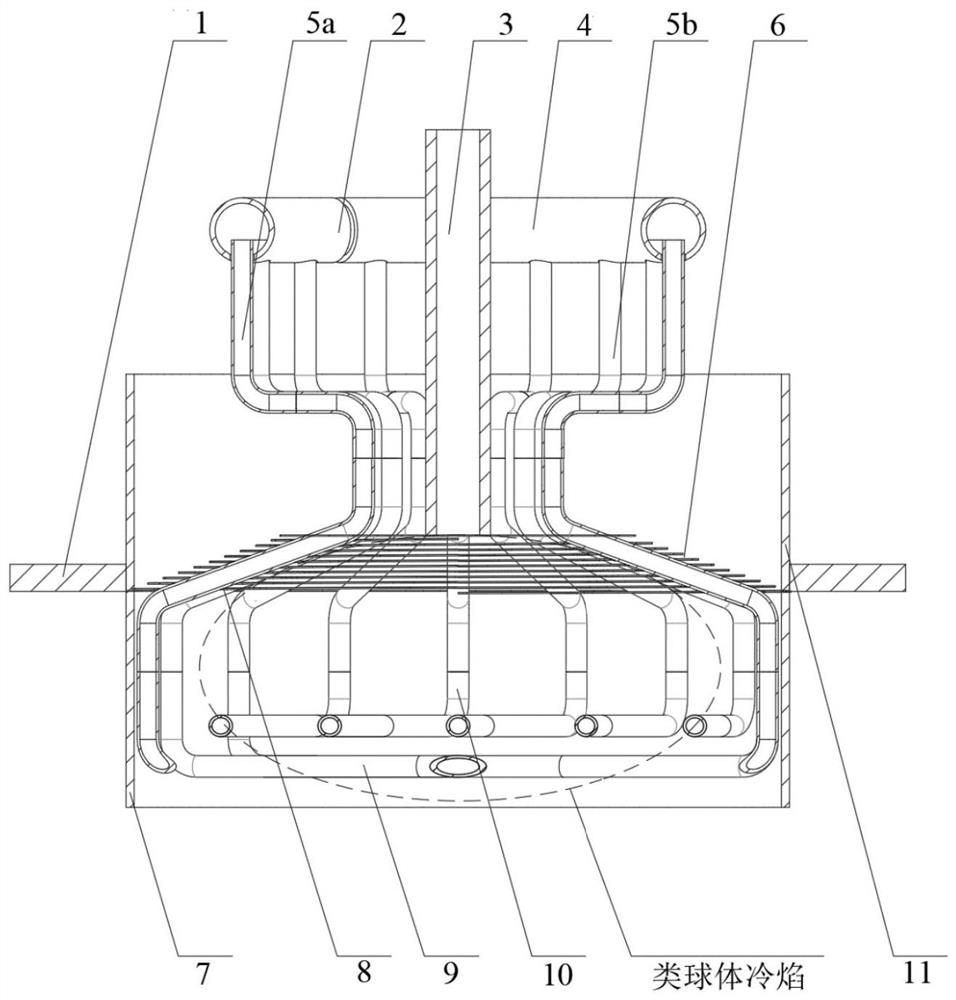

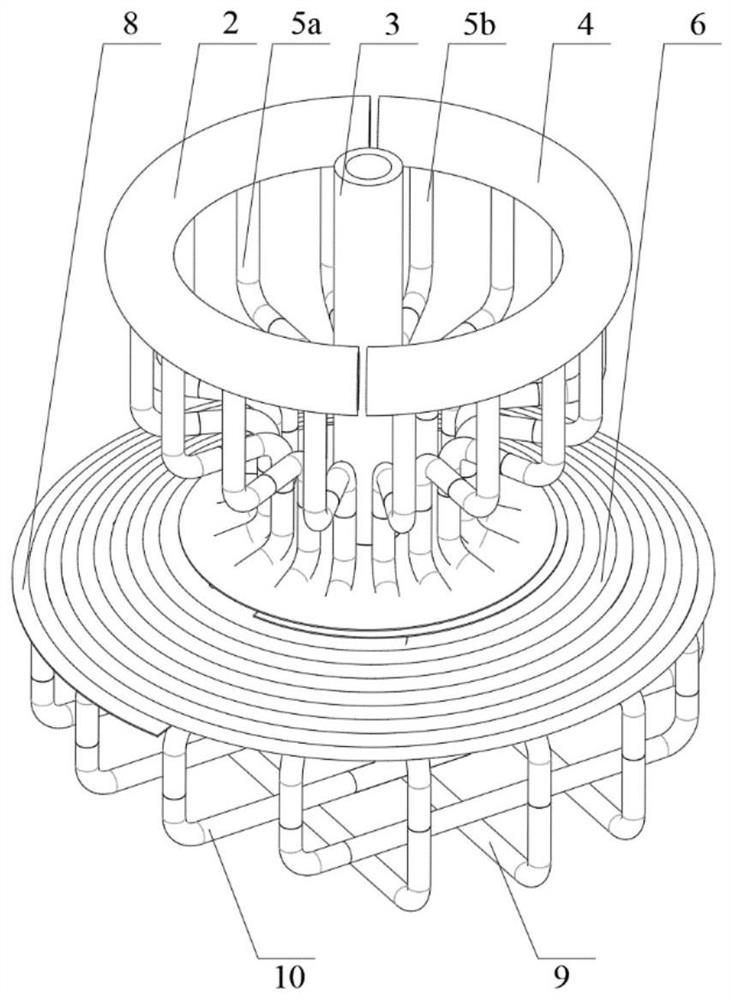

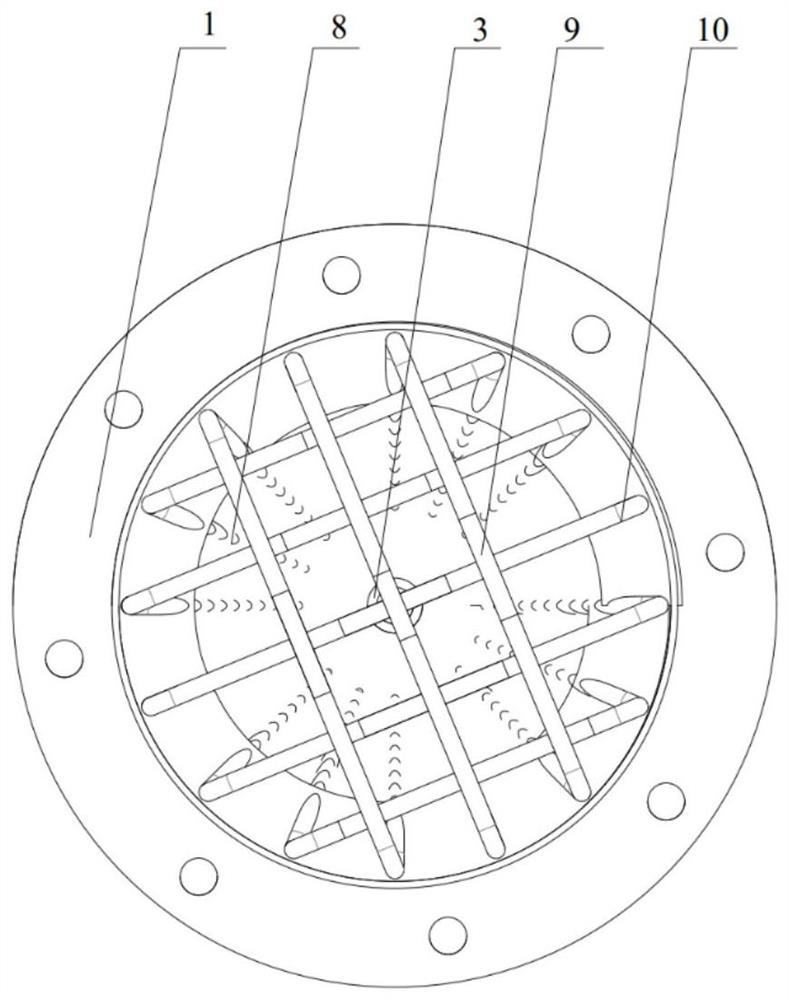

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] refer to Figure 1-Figure 6 , a spiral ring rib water-cooled cold flame gas burner, the main structure of which is that the mixed air flow is figure 1 The "step"-shaped mixed gas inlet formed by multiple sets of spiral ring ribs 8 above the upper part enters; the annular water cooling pipe 5 is connected with the multiple sets of spiral ring ribs 8 by welding to form a ribbed cooling water pipe. The ribs 8 are arranged at an angle of θ with the axis of the burner; the annular water cooling pipes 5 are inclined at equal intervals along the circumferential direction, and the installation angle is the same as the inclination angle of the spiral annular ribs 8; the multiple groups of spiral annular ribs 8 are arranged with the first-level annular cooling water pipes. 5 constitutes an anti-tempering intake micro-channel 6, and the outlet constitutes a "ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com