Ethylene/alpha-olefin copolymer and preparation method therefor

An olefin copolymer, ethylene technology, applied in the field of ethylene/α-olefin copolymer and its preparation, can solve the problems of reducing power generation efficiency and leakage, and achieve the effects of excellent insulation properties and high volume resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] In addition, the preparation method may further include the steps of: filtering the material obtained in the step (S3), washing and drying the filtrate, thereby obtaining an ethylene / α-olefin copolymer.

[0074] Composition for encapsulant film and encapsulant film

[0075] The ethylene / α-olefin copolymer of the present invention can be made into a resin composition by including other materials, and the resin composition can be used as various molded articles by molding by injection or extrusion. In particular, the copolymer can be used as an encapsulant to encapsulate devices in various optoelectronic devices, for example, can be used as an industrial material that can be applied to a lamination process by heating, but its use is not limited thereto.

[0076] In particular, the ethylene / α-olefin copolymer of the present invention can be processed into a composition for an encapsulant film, for example, a silane-modified resin composition or an aminosilane-modified resi...

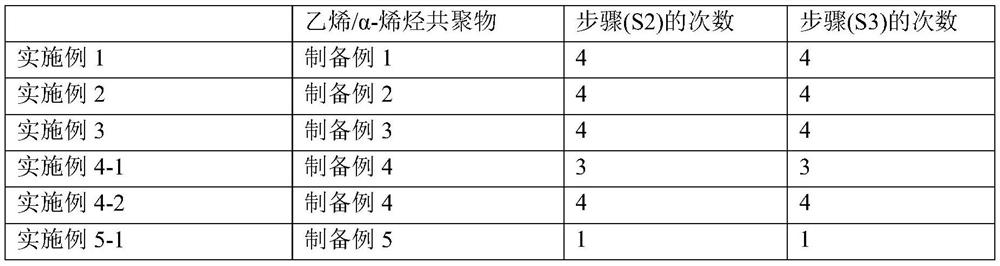

Embodiment

[0112] Hereinafter, the present invention will be described in more detail with reference to Examples. However, the examples are provided for illustration only, and the scope of the present invention is not limited thereto.

[0113] Catalyst preparation

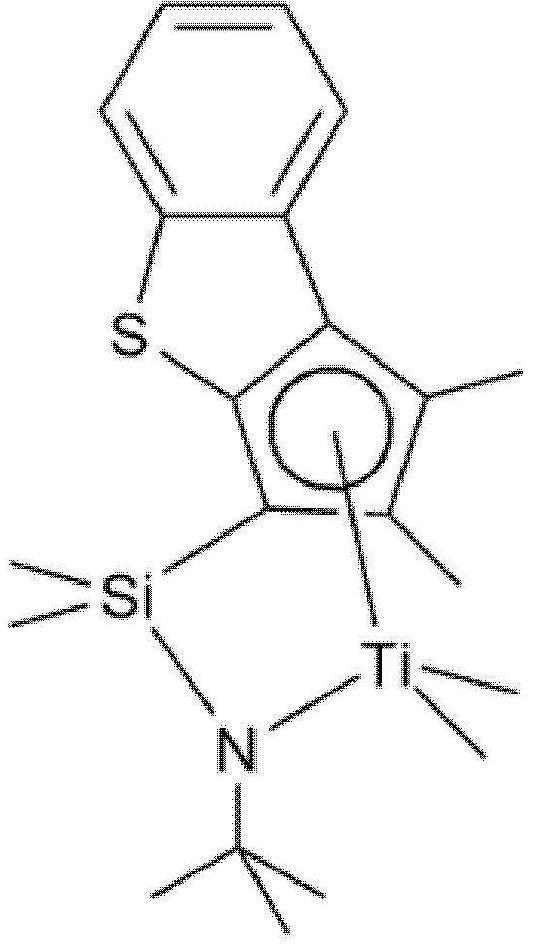

[0114] (1) Preparation of Ligand Compounds

[0115]

[0116] Weigh and add 4.65 g (15.88 mmol) of chloro(1,2-dimethyl-6,7-dihydro-3H-benzo[b]cyclopenta[d]thiophene- 3-yl) dimethylsilane, and inject 80ml of THF thereinto. Inject tBuNH into it at room temperature 2 (4eq, 6.68ml), and reacted at room temperature for 3 days. After the reaction was completed, THF was removed, and the resulting reaction product was filtered with hexane. After drying the solvent, 4.50 g (86%) of a yellow liquid were obtained.

[0117] 1 H NMR (in CDCl 3 Medium, 500MHz): δ7.99(d,1H), δ7.83(d,1H), δ7.35(dd,1H), δ7.24(dd,1H), δ3.49(s,1H), δ2.37(s, 3H), δ2.17(s, 3H), δ1.27(s, 9H), δ0.19(s, 3H), δ-0.17(s, 3H).

[0118] (2) Preparation of tran...

preparation example 1

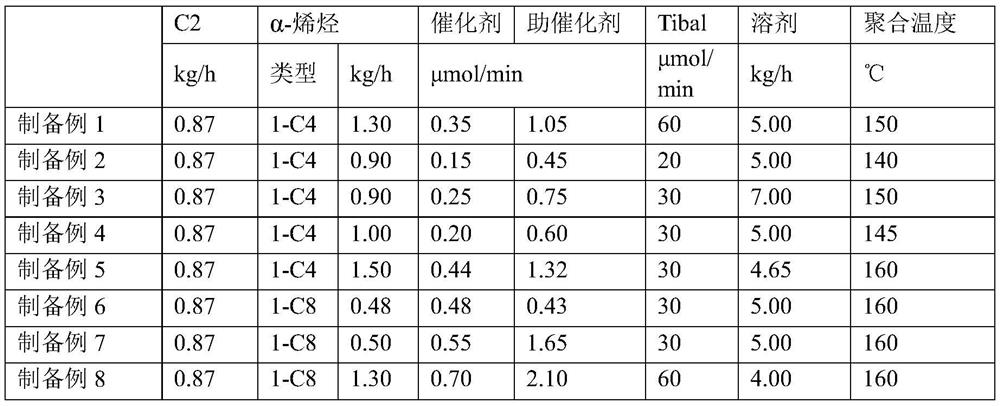

[0124] A 1.5 L continuous process reactor was preheated at 120°C while injecting hexane solvent at 5.00 kg / h and 1-butene at 1.30 kg / h. Inject triisobutylaluminum (Tibal, 60 μ mol / min), the transition metal compound (0.35 μ mol / min) of [formula 1] and tetrakis (pentafluorophenyl) borate dimethylanilinium cocatalyst ( 1.05 μmol / min). Then, ethylene (0.87 kg / h) and hydrogen (20 cc / min) were injected into the reactor, and copolymerization was continuously performed for 60 minutes or more while maintaining a pressure of 89 bar and 150° C. to prepare a copolymer. After drying in a vacuum oven for more than 12 hours, an ethylene / α-olefin copolymer was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com