Insulating anti-electrostatic flame-retardant film and processing method therefor

A processing method and flame retardant film technology, applied in the field of plastic processing, can solve problems such as easy generation of static electricity, inconvenient film materials, and affecting printing effects, etc., and achieve high volume resistance and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

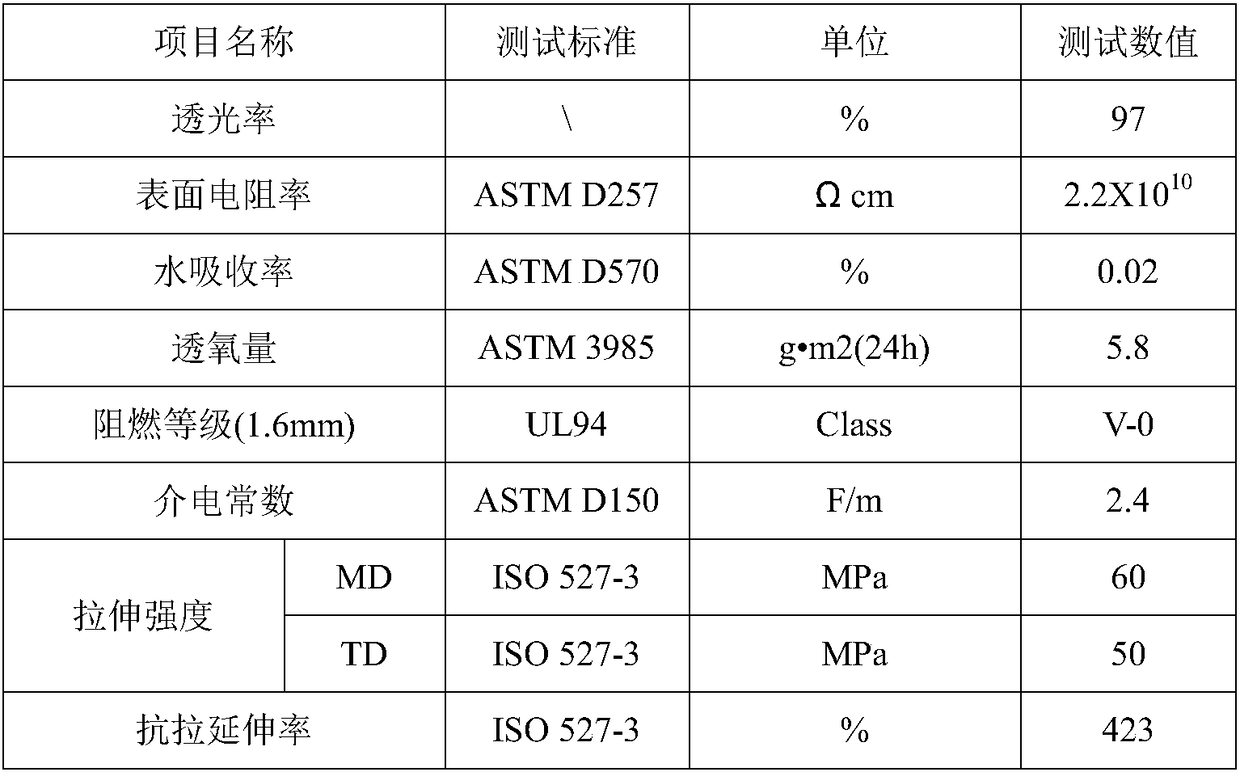

[0037] In this embodiment, a kind of insulating antistatic and flame retardant film dedicated to aviation comprises polyethylene, mica powder, antistatic agent, ten-scented diphenyl ether, antimony trioxide, dispersant, and thermal stabilizer; by weight percentage, the The composition of the raw material is: 37% polyethylene, 5% mica powder, 5% antistatic agent, 15% diphenyl ether, 30% antimony trioxide, 3% dispersant, and 5% heat stabilizer. The obtained material properties are as follows:

[0038]

Embodiment 2

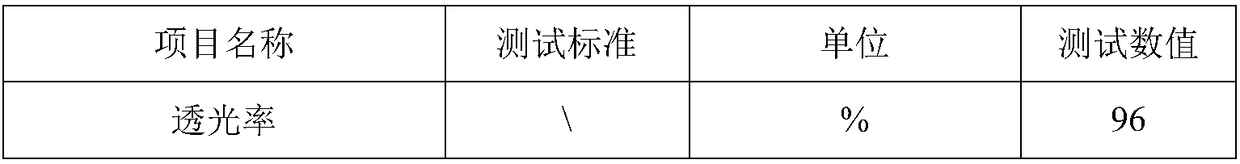

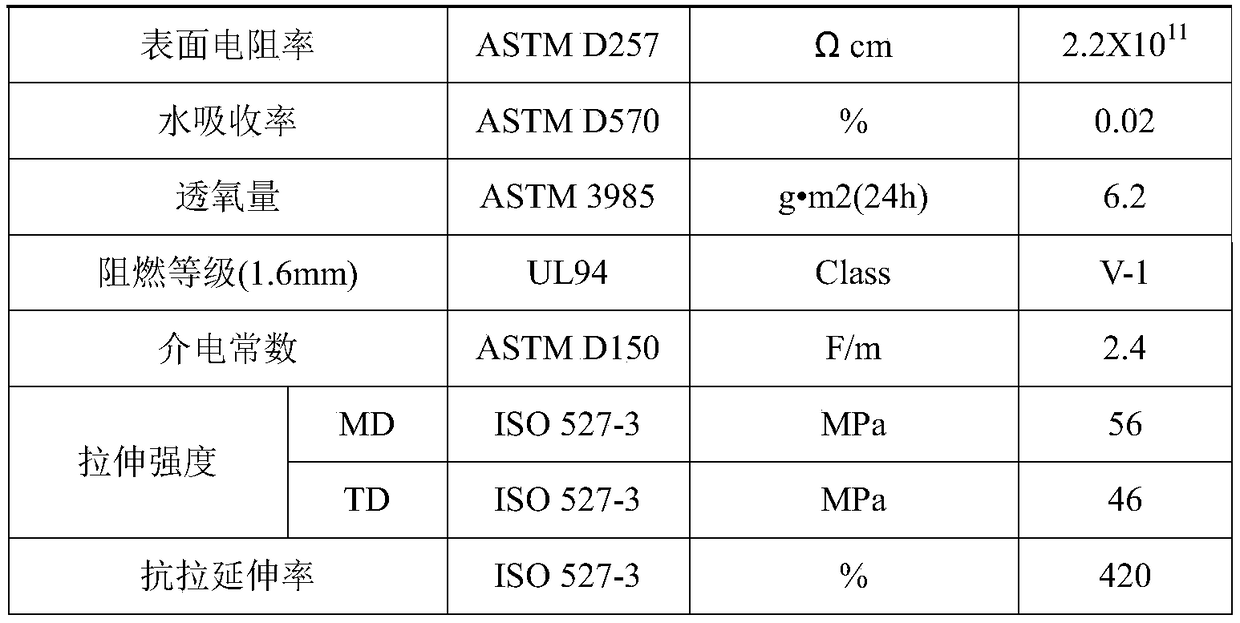

[0040] In this embodiment, an insulating, antistatic and flame retardant film dedicated to aviation includes polyethylene, mica powder, antistatic agent, decathin diphenyl ether, antimony trioxide, dispersant, and heat stabilizer;

[0041] In terms of weight percentage, the components of the raw materials are: 35% polyethylene, 4% mica powder, 6% antistatic agent, 10% deca-diphenyl ether, 35% antimony trioxide, 4% dispersant, heat Stabilizer 6%. The obtained material properties are as follows:

[0042]

[0043]

Embodiment 3

[0045] In this embodiment, an insulating, antistatic and flame retardant film dedicated to aviation includes polyethylene, mica powder, antistatic agent, decathin diphenyl ether, antimony trioxide, dispersant, and heat stabilizer;

[0046] In terms of percentage by weight, the components of the raw materials are: 36% polyethylene, 5% mica powder, 5% antistatic agent, 13% ten-olfactory diphenyl ether, 32% antimony trioxide, 3% dispersant, heat Stabilizer 6%. The obtained material properties are as follows:

[0047]

[0048] It can be seen from the tables in Example 1, Example 2 and Example 3 that the special insulating antistatic flame retardant film for aviation prepared by the present invention has better light transmission, insulation, antistatic properties and high mechanical strength.

[0049] Process as follows:

[0050] 1) Feeding; place the ingredients in the hoppers respectively;

[0051] 2) Batching: The materials are proportioned according to the formula ratio,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com