A flame-retardant high-tear-resistant liquid silicone resin

A technology of liquid silicon and MQ silicone resin, which is applied in the field of silicone resin, can solve the problems of insufficient storage stability, flame retardancy and tear resistance, etc., and achieve improved flame retardancy, excellent tear resistance, and good physical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

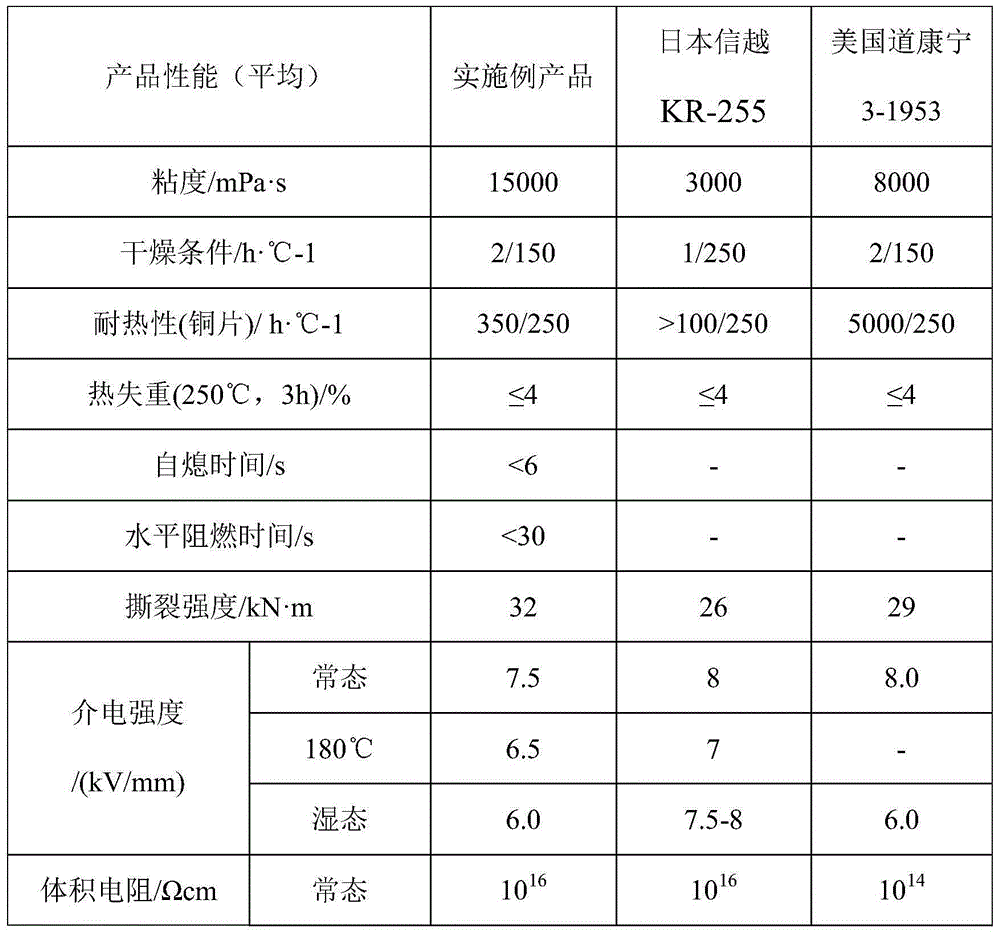

[0023] Embodiment 1. Preparation of a flame-retardant and high-tear-resistant liquid silicone resin

[0024] A flame-retardant and high-tear-resistant liquid silicone resin, in parts by weight, comprising 100 parts of MQ silicone resin, 50 parts of linear phenyl vinyl siloxane as reactive diluent, and linear phenyl modified phenyl vinyl siloxane as crosslinking agent. 5 parts of hydrogen siloxane, 5 parts of fumed silicon dioxide as the reinforcing agent, and 0.01 part of dimethyl fumarate as the temperature-sensitive inhibitor.

[0025] The ratio of the M link to the Q link in the above-mentioned MQ silicone resin is 0.6.

[0026] The specific surface area of the above-mentioned fumed silica is 160m 2 / g.

[0027] The linear phenyl vinyl siloxane comprises the following steps: 50 parts of bis(methylphenyl vinyl) disiloxane and 150 parts of diphenyl dimethoxysilane are put into the reactor, Raise the temperature to 85°C, add an appropriate amount of 30 parts of water and ...

Embodiment 2

[0033] 3) After passing the physical performance test of the banburying material, grind to remove its blocky material, then add the inhibitor dimethyl fumarate, and the crosslinking agent linear phenyl-modified hydrogen-containing siloxane, stir for 2 hours, and press filter to obtain Liquid silicone. Embodiment 2, preparation of a flame-retardant high-tear-resistant liquid silicone resin

[0034] A flame-retardant and high-tear-resistant liquid silicone resin, in parts by weight, comprising 150 parts of MQ silicone resin, 100 parts of linear phenyl vinyl siloxane as reactive diluent, and linear phenyl modified phenyl vinyl siloxane as crosslinking agent. 10 parts of hydrogen siloxane, 20 parts of fumed silica as a reinforcing agent, and 0.15 parts of dimethyl fumarate as a thermosensitive inhibitor.

[0035] The ratio of the M link to the Q link in the above-mentioned MQ silicone resin is 0.8.

[0036] The specific surface area of the above-mentioned fumed silica is 300m ...

Embodiment 3

[0043] 3) After passing the physical performance test of the banburying material, grind to remove its blocky material, then add the inhibitor dimethyl fumarate, and the crosslinking agent linear phenyl-modified hydrogen-containing siloxane, stir for 2 hours, and press filter to obtain Liquid silicone. Embodiment 3. Preparation of a flame-retardant and high-tear-resistant liquid silicone resin

[0044] A flame-retardant and high-tear-resistant liquid silicone resin, in parts by weight, including 120 parts of MQ silicone resin, 80 parts of linear phenyl vinyl siloxane as reactive diluent, and linear phenyl modified phenyl vinyl siloxane as crosslinking agent. 6 parts of hydrogen siloxane, 10 parts of fumed silica as a reinforcing agent, and 0.08 parts of dimethyl fumarate as a thermosensitive inhibitor.

[0045] The ratio of the M link to the Q link in the above-mentioned MQ silicone resin is 0.7.

[0046] The specific surface area of the above-mentioned fumed silica is 240m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com