Bionic dry-wet adhesive force self-adjusting dressing and preparation method and application thereof

An adhesion and self-regulating technology, applied in medical science, bandages, etc., can solve the problems of reducing patient experience, difficulty maintaining shape, and dressing softening, etc., and achieve the effect of increasing experience, short reaction time, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

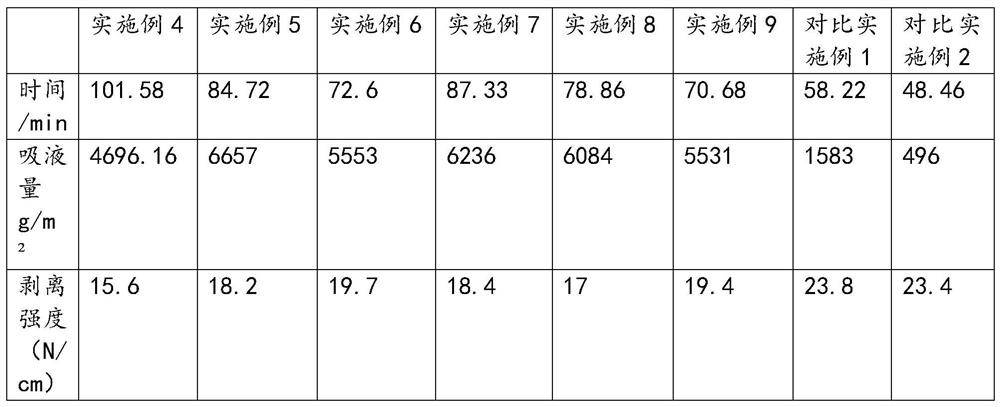

Examples

Embodiment 1

[0040] Microcrystalline Cellulose Pretreatment Method

[0041] Mix 50g of microcrystalline cellulose and 800ml of deionized water evenly under ultrasonic waves, shear in a high-speed shear for 0.5h (8000r / min), centrifuge for 15min (9800r / min), wash three times with absolute ethanol, and then naturally Dry to obtain microcrystalline cellulose with a size of 20-50 μm.

Embodiment 2

[0043] Microcrystalline Cellulose Pretreatment Method

[0044] Mix 50g of microcrystalline cellulose and 800ml of deionized water evenly under ultrasonic waves, shear in a high-speed shear for 1.5h (8000r / min), centrifuge for 10min (9800r / min), wash three times with absolute ethanol, and then naturally Dry to obtain microcrystalline cellulose with a size of 20-50 μm.

Embodiment 3

[0046] Microcrystalline Cellulose Pretreatment Method

[0047]Mix 50g of microcrystalline cellulose and 800ml of deionized water evenly under ultrasonic waves, shear in a high-speed shear for 1h (8000r / min), centrifuge for 10min (9800r / min), wash three times with absolute ethanol, and then dry naturally , to obtain microcrystalline cellulose with a size of 20-50 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com