Nickel black-graphene composite photothermal conversion film and preparation method thereof

A graphene composite, photothermal conversion technology, applied in graphene, chemical instruments and methods, optics, etc., can solve the problems of high cost and limited wide application, and achieve the effect of simple preparation process and wide light absorption wavelength range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

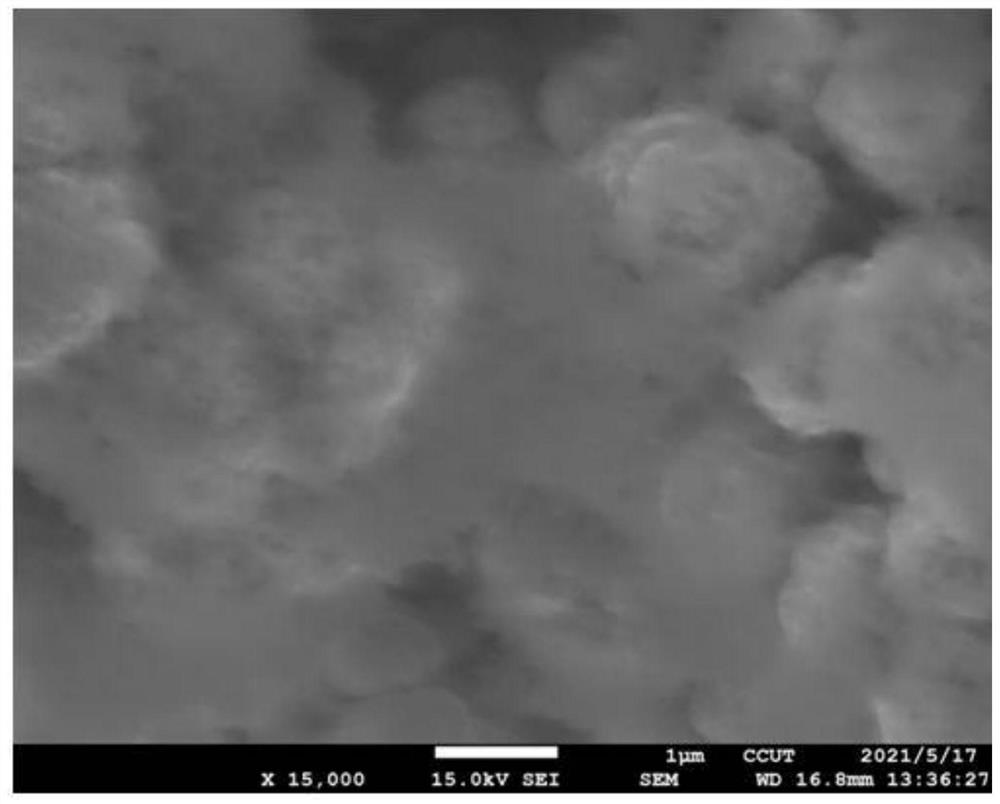

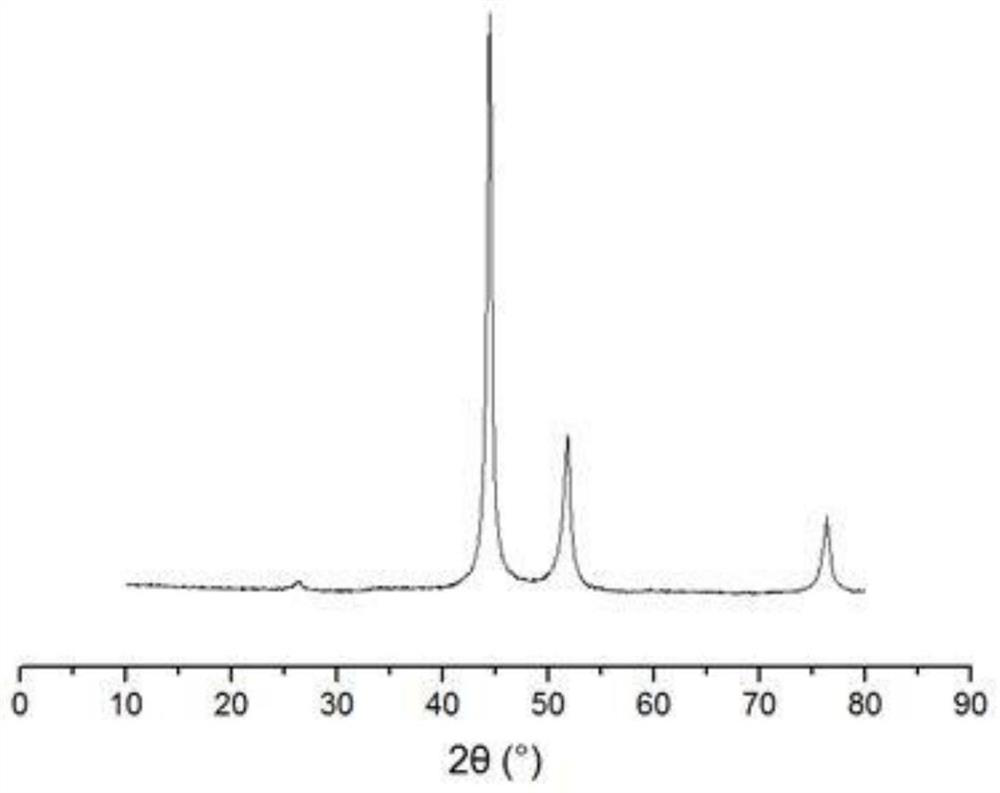

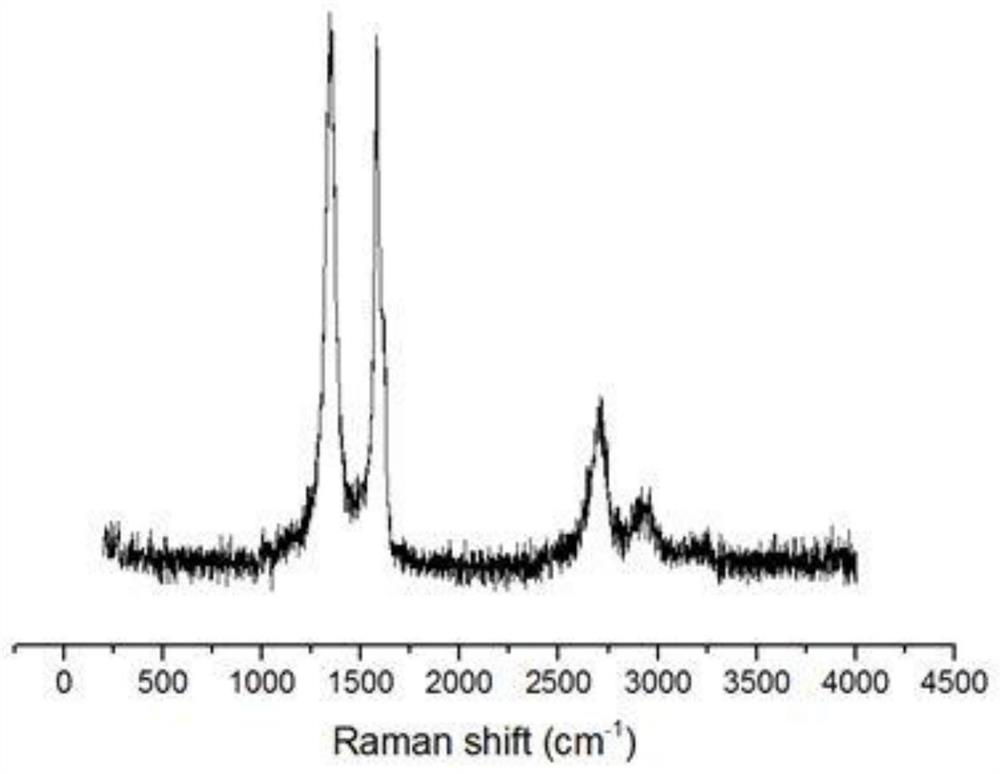

[0031] Add 1.32g of ammonium sulfate and 0.42g of nickel sulfate to 200ml of deionized water, and keep stirring at room temperature until fully dissolved to form an electrolyte solution; connect the foamed nickel to the cathode and the graphite foil to the anode, and connect the connected Adjust the electrode distance and put it into the electrolyte; turn on the switch of the external DC power supply, and react at 13V for 10 minutes; wash the plated nickel black-graphene light-to-heat conversion film in deionized water, take it out and bake it in an oven at 60°C Let dry for 12 hours. Placed on the evaporation cup under the light of 1 sun, the light-vapor energy conversion efficiency is 136.94%, and the vapor permeability is 2.00 kg / m 2 h.

Embodiment 2

[0033] Add 1.32g of ammonium sulfate and 0.42g of nickel sulfate to 200ml of deionized water, and keep stirring at room temperature until fully dissolved to form an electrolyte solution; connect the foamed nickel to the cathode and the graphite foil to the anode, and connect the connected Adjust the electrode distance and put it into the electrolyte; turn on the switch of the external DC power supply, and react at 13V for 20 minutes; wash the plated nickel black-graphene photothermal conversion film in deionized water, take it out and bake it in an oven at 60°C Let dry for 12 hours. Placed on the evaporation cup under the light of 1 sun, the light-vapor energy conversion efficiency is 138.49%, and the vapor permeability is 2.02 kg / m 2 h.

Embodiment 3

[0035] Add 1.32g of ammonium sulfate and 0.42g of nickel sulfate to 200ml of deionized water, and keep stirring at room temperature until fully dissolved to form an electrolyte solution; connect the foamed nickel to the cathode and the graphite foil to the anode, and connect the connected Adjust the distance between the electrodes and put them into the electrolyte; turn on the switch of the external DC power supply, and react at 13V for 30 minutes; wash the plated nickel black-graphene light-to-heat conversion film in deionized water, take it out and bake it in an oven at 60°C Let dry for 12 hours. Placed on the evaporation cup under the light of 1 sun, the light-steam energy conversion efficiency is 162.48%, and the vapor permeability is 2.37 kg / m 2 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com