Preparation method and application of hydrogel flexible touch sensor

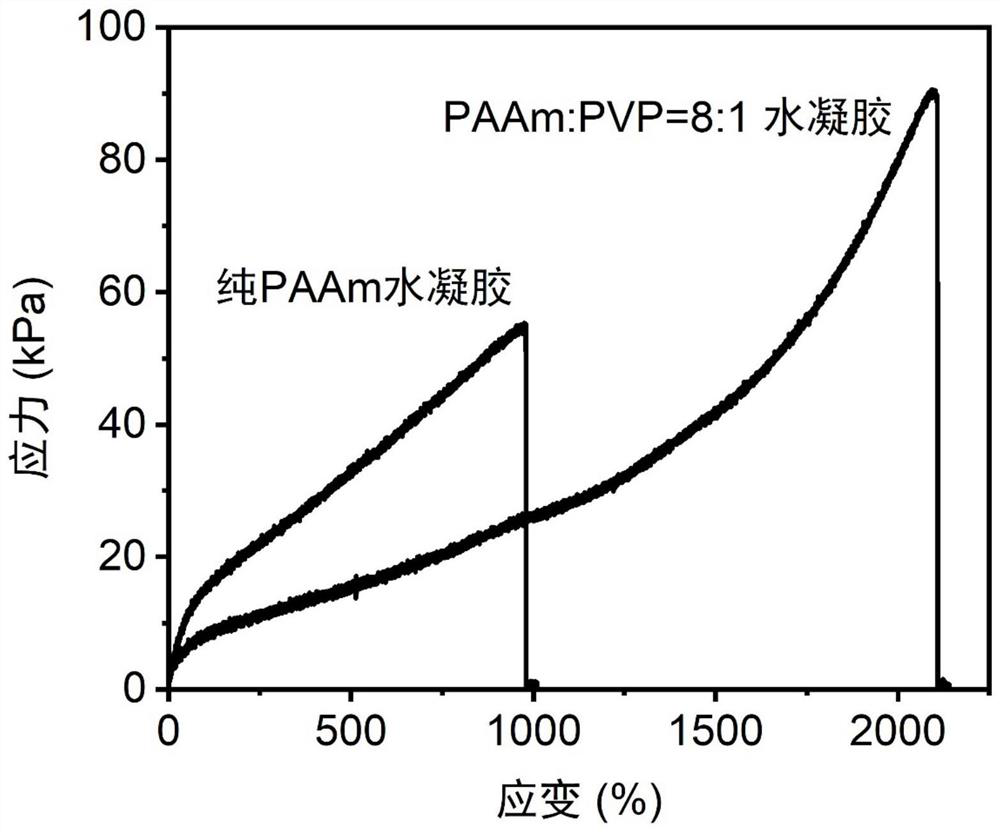

A tactile sensor and hydrogel flexibility technology, applied in the field of flexible wearable sensing, can solve the problems of low stretch rate of hydrogel, low stress sensing performance, insensitive detection of physiological signal changes, etc. Effects of range and detection sensitivity, high sensitivity, excellent elasticity and stretchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

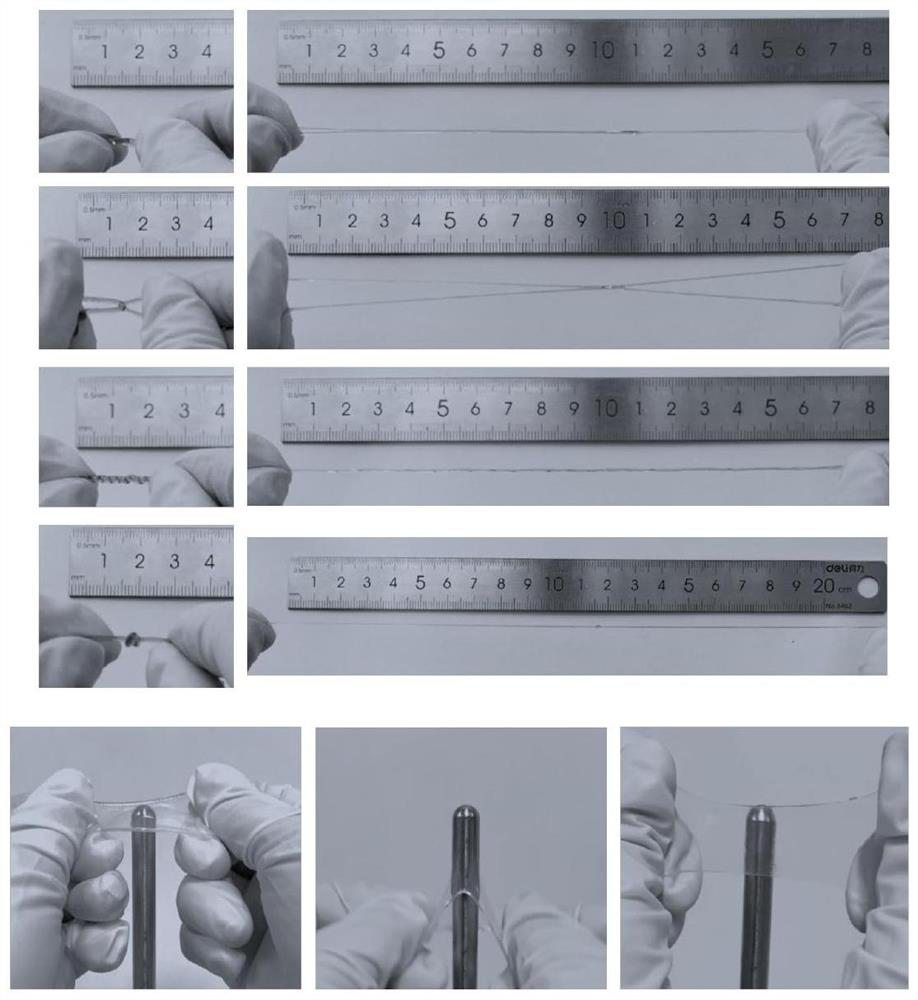

[0030] (1) AAm and PVP were dissolved in deionized water at a molar ratio of 8:1, and stirred with a magnetic stirrer until completely dissolved;

[0031] (2) Dissolve crosslinking agent MBA and photoinitiator APS with 0.1% and 1.5% AAm monomer mass fractions respectively in (1) solution and stir on a magnetic stirrer (temperature ≤ 25° C.) for 3 hours;

[0032] (3) After the solution of (2) is stirred evenly, add PEDOT:PSS with an AAm mass fraction of 0.11%, and place it on a magnetic stirrer and stir slowly until there are no flocs in the solution;

[0033] (4) Take the hydrogel precursor solution in (3) in the PDMS mold, and use a UV lamp with a wavelength of 365nm (optical power density: 535mw cm -2 ) light for 200s to obtain a stretchable conductive hydrogel;

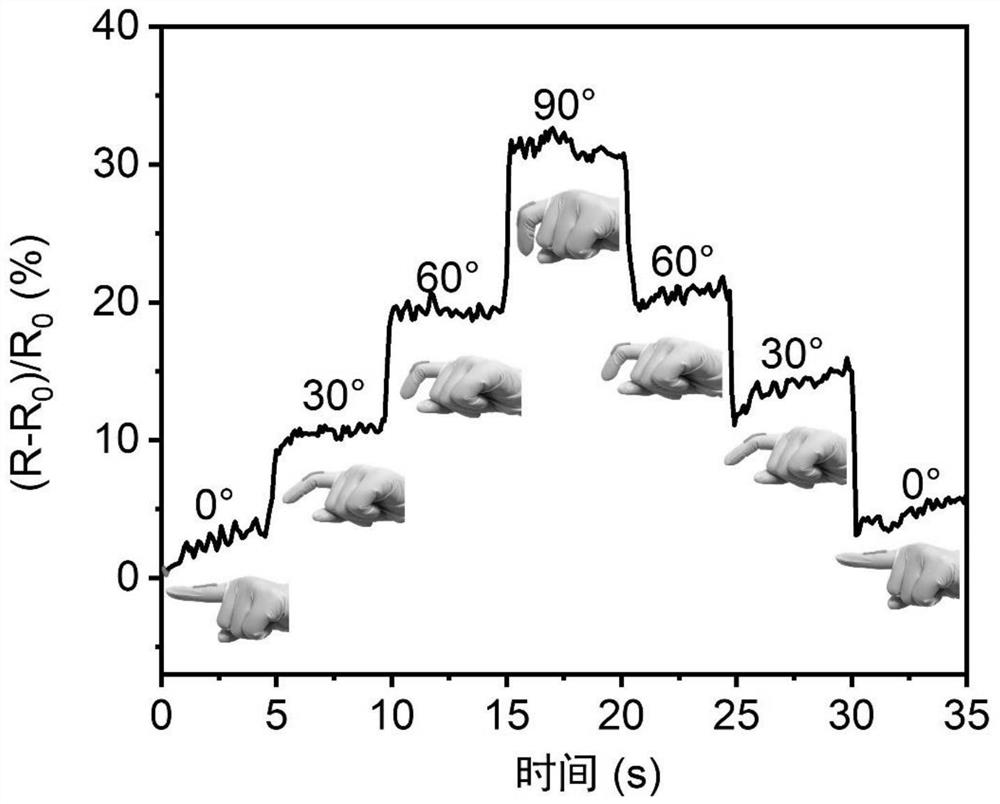

[0034] (5) Take the flexible conductive hydrogel in (4), attach it to the joints of the fingers, straighten the fingers at 30°, 60°, and 90°, then return in the order of 90°, 60°, and 30°, and test Changes in the...

Embodiment 2

[0037] (1) AAm and PVP were dissolved in deionized water at a molar ratio of 8:1, and stirred with a magnetic stirrer until completely dissolved;

[0038] (2) Dissolve crosslinking agent MBA and photoinitiator APS with 0.1% and 1.5% AAm monomer mass fractions respectively in (1) solution and stir on a magnetic stirrer (temperature ≤ 25° C.) for 3 hours;

[0039] (3) After the solution of (2) is stirred evenly, add PEDOT:PSS with an AAm mass fraction of 0.11%, and place it on a magnetic stirrer and stir slowly until there are no flocs in the solution;

[0040](4) Take the hydrogel precursor solution in (3) in the PDMS mold, and use a UV lamp with a wavelength of 365nm (optical power density: 535mw cm -2 ) light for 200s to obtain a stretchable conductive hydrogel;

[0041] (5) Take the flexible conductive hydrogel in (4) and attach it to the wrist and elbow to detect the bending degree and speed of the finger.

[0042] The test results show that the flexible tactile sensor ca...

Embodiment 3

[0044] (1) AAm and PVP were dissolved in deionized water at a molar ratio of 8:1, and stirred with a magnetic stirrer until completely dissolved;

[0045] (2) Dissolve crosslinking agent MBA and photoinitiator APS with 0.1% and 1.5% AAm monomer mass fractions respectively in (1) solution and stir on a magnetic stirrer (temperature ≤ 25° C.) for 3 hours;

[0046] (3) After the solution of (2) is stirred evenly, add PEDOT:PSS with an AAm mass fraction of 0.11%, and place it on a magnetic stirrer and stir slowly until there are no flocs in the solution;

[0047] (4) Take the hydrogel precursor solution in (3) in the PDMS mold, and use a UV lamp with a wavelength of 365nm (optical power density: 535mw cm -2 ) light for 200s to obtain a stretchable conductive hydrogel;

[0048] (5) Take the flexible conductive hydrogel in (4) and attach it to the throat, and repeat the words "Hi", "Hello" and "Hydrogel" in three different syllables in order to distinguish the content of the subjec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com