High-strength low-shrinkage PETG-G material for 3D printer consumables and preparation method thereof

A technology of PETG-G and 3D printer, which is applied in the field of PETG-G material and its preparation, and can solve the problems of limiting PETG application, high temperature of wire drawing and printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

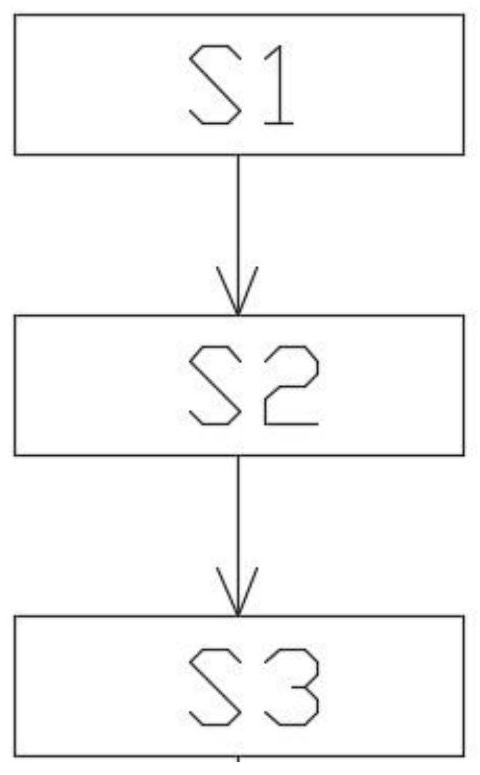

[0053] Described a kind of preparation method for the PETG-G material of high strength and low shrinkage of 3D printer consumables, it comprises the steps:

[0054] S1. Stir the PETG resin, PBAT resin, ABS resin and diffusion oil evenly with a high-speed mixer, so that the diffusion oil is evenly dispersed on the surface of the resin;

[0055] S2, adding compatibilizer, antioxidant, lubricant and stirring evenly to obtain the mixed material;

[0056] S3. The uniformly mixed material is added from the main feeding port of the extruder, and the material is melted, extruded, drawn, water-cooled, pelletized, and dried to obtain high-strength and low-shrinkage PETG-G pellets.

[0057] In the step (S1), the stirring speed is 300-500 rpm, and the stirring time is 5-10 minutes; in the step (S3), the extruder is a SJ35 type twin-screw extruder, and the extrusion speed is 200~ 350 rpm, the temperature of each heating zone is independently 170-195°C. After step (S3), it is processed in...

Embodiment 1

[0068] Pour 1800 grams of PETG (Korean SK company, the brand name is K2012), 1200 grams of PBAT resin (Zhuhai Wantong Chemical Co., Ltd., the brand name is PBAT0120), and 150 grams of ABS resin into the high mixer, add 15 grams of diffusion oil, and use 300 Stir at a stirring rate of rev / min for 5min, so that the diffusion oil is evenly dispersed on the surface of the resin pellets; compatibilizer styrene-acrylonitrile-maleic anhydride copolymer 60 grams, lubricant interacid amide 9 grams, antioxidant 10103 gram into a high-mixer and stir evenly; use a stirring speed of 500 rpm to stir for 10 minutes, let it stand for 5 minutes, and then add a twin-screw machine to extrude.

[0069] The extrusion conditions of the twin-screw machine are: the temperature of each temperature section of the extruder from the feed port to the discharge die is 170°C, 175°C, 175°C, 180°C, 180°C, 180°C, 185°C, 185°C , 190°C, 190°C, 190°C, the extruder speed is 250 rpm. After the material is melted, ...

Embodiment 2

[0072] Pour 2100 grams of PETG (Korean SK company, the brand is K2012), 900 grams of PBAT resin (Zhuhai Wantong Chemical Co., Ltd., the brand is PBAT0120), 180 grams of ABS resin into the high mixer, add 15 grams of diffusing oil, and use 300 Stir at a stirring rate of rev / min for 5min, so that the diffusion oil is evenly dispersed on the surface of the resin pellets; compatibilizer styrene-acrylonitrile-maleic anhydride copolymer 60 grams, lubricant interacid amide 9 grams, antioxidant 10103 gram into a high-mixer and stir evenly; use a stirring speed of 500 rpm to stir for 10 minutes, let it stand for 5 minutes, and then add a twin-screw machine to extrude.

[0073] The extrusion conditions of the twin-screw machine are: the temperature of each temperature section of the extruder from the feed port to the discharge die is 170°C, 175°C, 175°C, 180°C, 180°C, 180°C, 185°C, 185°C , 190°C, 190°C, 190°C, the extruder speed is 250 rpm. After the material is melted, extruded, drawn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com