Rare earth recovery system and recovery process thereof

A recovery system and rare earth technology, applied in the direction of improving process efficiency, etc., can solve the problems of low extraction rate and low extraction purity, achieve high extraction rate, reduce waste, and improve filter press efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a structure of a rare earth recovery system.

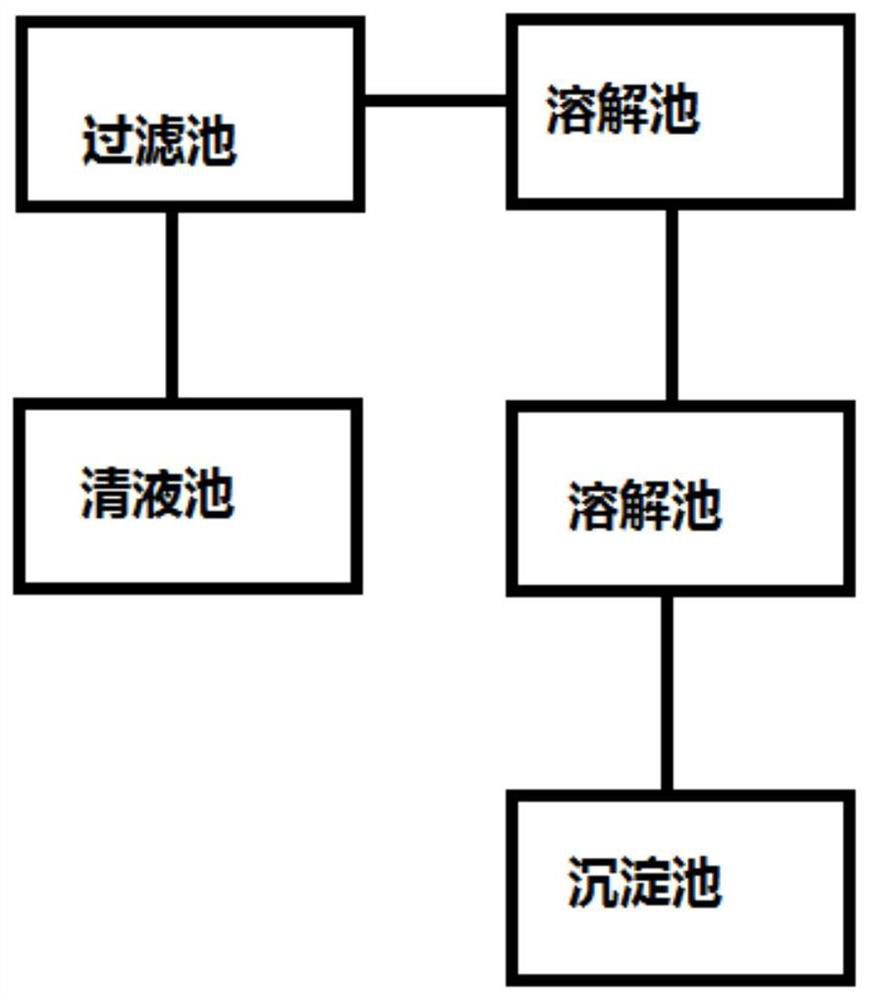

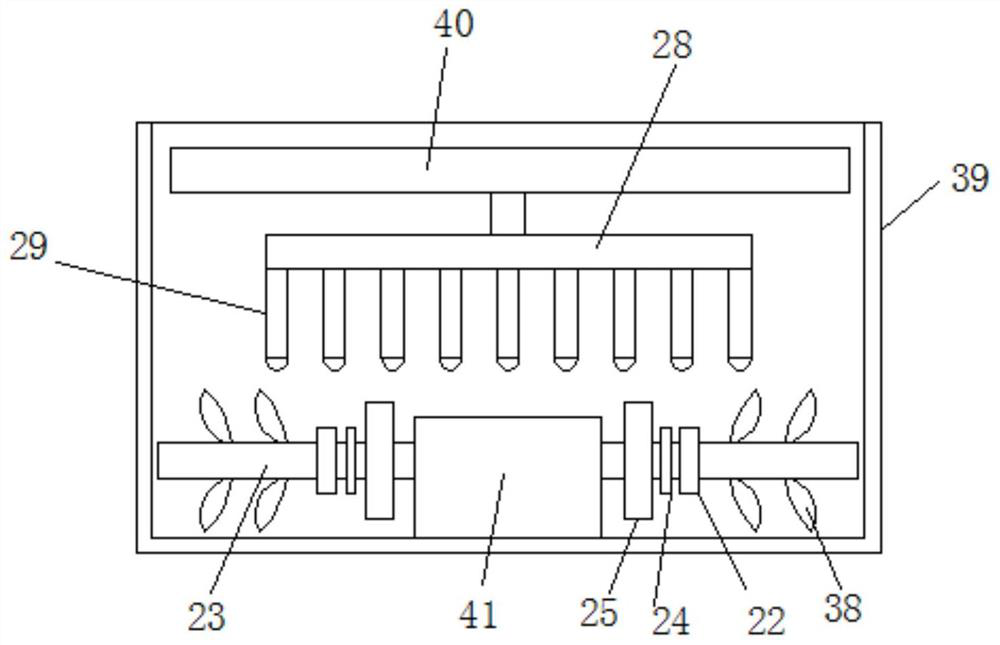

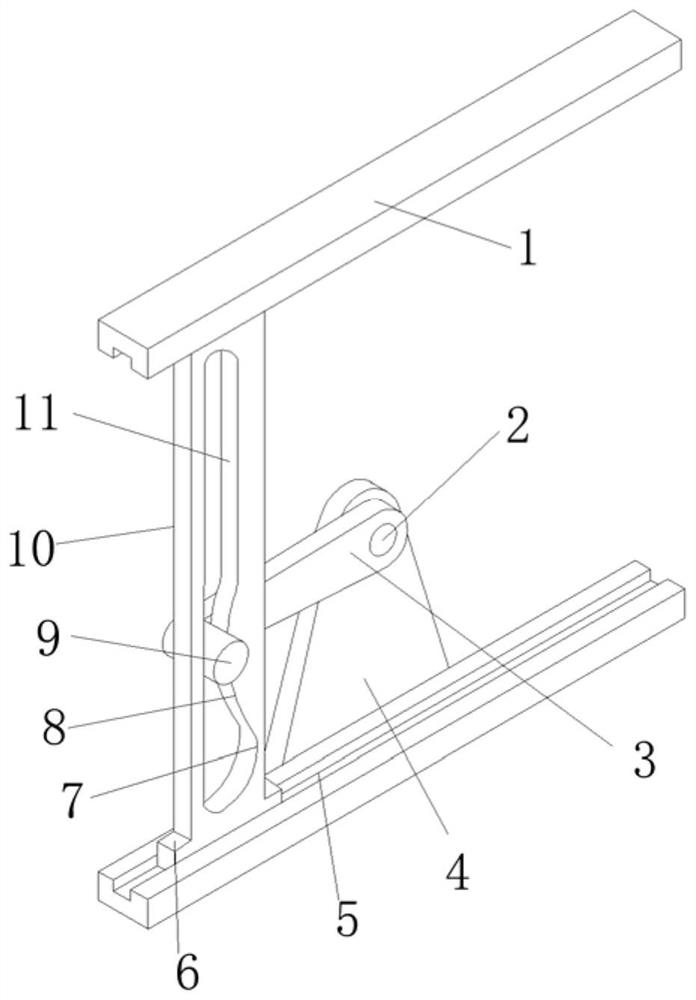

[0048] Such as figure 1 As shown, a rare earth recovery system includes a filter tank, a clear liquid tank, a sedimentation tank and two dissolution tanks 39, such as figure 2 As shown, the dissolution tank 39 includes a filter press device and a mixing device with a linkage structure, and the filter press device includes a filter press drive mechanism 40 and a filter press rod 29, and the filter press drive mechanism 40 is located at the The inside of the dissolving tank 39, and the filter press driving mechanism 40 is used to drive the filter press rod 29 to press filter the filtrate in the dissolving tank 39;

[0049] The mixing device is located at the inner bottom surface of the dissolving tank 39, and comprises a linkage assembly 41 equipped with a cam 15 and a stirring blade 38 arranged on the side of the linkage assembly 41 for stirring the filtrate in the dissolving tank 39, and the cam 1...

Embodiment 2

[0058] This embodiment provides a rare earth recovery process, using the rare earth recovery system provided in Example 1, comprising the following steps:

[0059] S1: Collect 250m 3 Leach the mother liquor of rare earth mine (test pH=4.8), put the mother liquor into the mixing tank, start stirring, add magnesium oxide (industrial grade, 85% MgO) while pouring the mother liquor, test the pH value of the supernatant, if pH<6.7 Magnesium oxide is then added until the pH of the supernatant reaches 6.7;

[0060] S2: Drain the mixed sediment slurry to the filter tank, and filter it in the filter tank, then drain the clear liquid above the filter tank to the clear liquid tank, and discharge the rare earth mud sediment at the bottom of the filter tank from the sludge discharge port to the dissolution tank ;

[0061] S3: Slowly add oxalic acid and polyethylene glycol solution with a mass ratio of 1:2 to the rare earth mud precipitate in the dissolution tank, adjust the pH value to 5...

Embodiment 3

[0065] This embodiment provides a rare earth recovery process, using the rare earth recovery system provided in Example 1, comprising the following steps:

[0066] S1: Collect 250m 3 Leach the mother liquor of rare earth mine (test pH=4.8), pour the mother liquor into the mixing tank, start stirring, add magnesium oxide (industrial grade, 85% MgO) while pouring the mother liquor, test the pH value of the supernatant, if the pH<7.2 Magnesium oxide is then added until the pH of the supernatant reaches 7.2;

[0067] S2: Drain the mixed sediment slurry to the filter tank, and filter it in the filter tank, then drain the clear liquid above the filter tank to the clear liquid tank, and discharge the rare earth mud sediment at the bottom of the filter tank from the sludge discharge port to the dissolution tank ;

[0068] S3: Slowly add oxalic acid and polyethylene glycol solution with a mass ratio of 1:10 to the rare earth mud precipitate in the dissolution tank, adjust the pH valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com