Vibration reduction connecting structure of boxboard type building, boxboard type steel structure building and construction method of boxboard type steel structure building

A vibration connection and steel structure technology, applied in building components, building structure, processing of building materials, etc., can solve problems such as noise and transmission vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

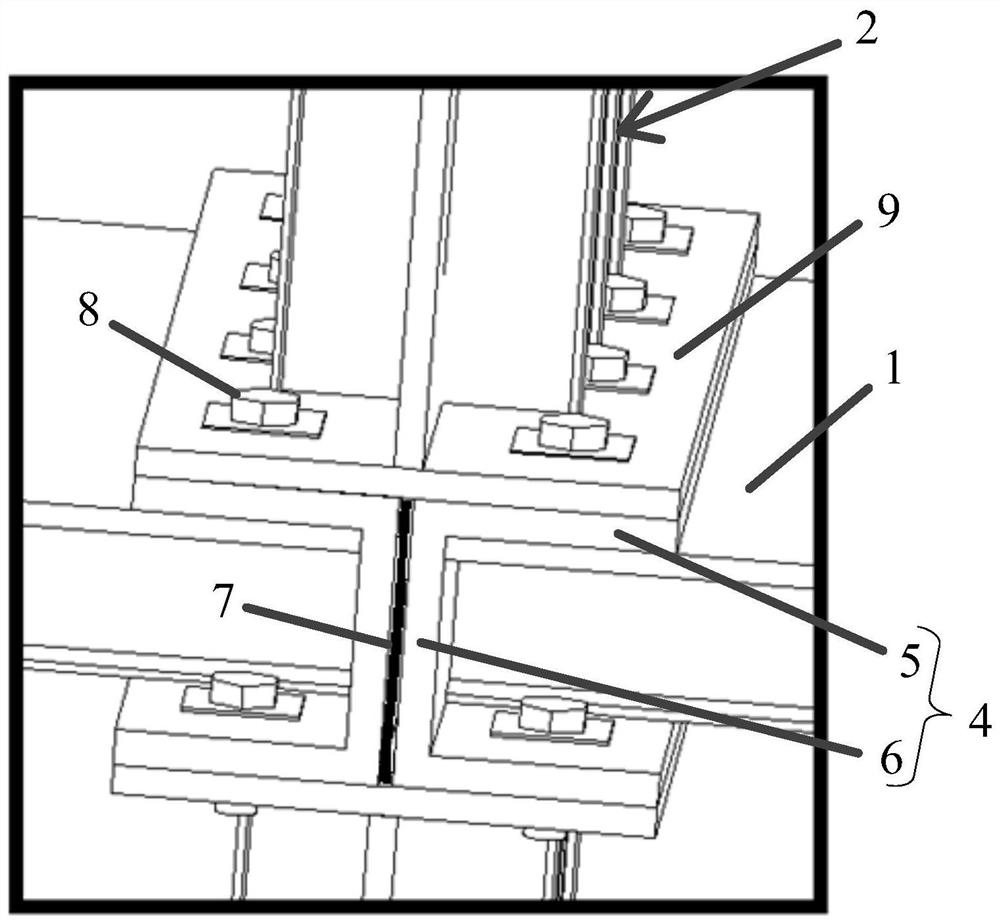

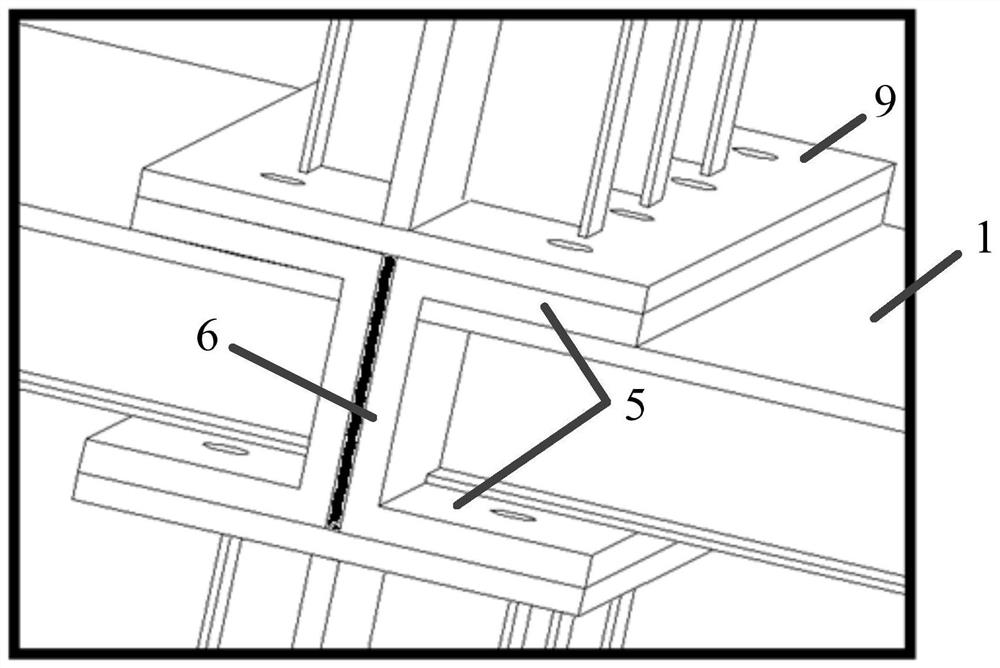

[0047] In this embodiment, a vibration-damping connection structure of a box-slab building is provided, such as image 3 and Figure 4 shown, which includes:

[0048] Steel floor slabs 1, the steel floor slabs 1 are arranged along the horizontal direction, and at least two adjacent steel floor slabs 1 are arranged on the same horizontal plane to form a floor of a box-slab steel structure building;

[0049] A steel support wallboard 2, the steel support wallboard 2 is a plate-shaped support structure arranged along the vertical direction; and the steel support wallboard 2 is fixedly connected to the steel floor 1;

[0050] The I-shaped connection assembly 3, the I-shaped connection assembly 3 is an I-shaped member composed of two U-shaped connectors 4 of U-shaped structure; the U-shaped connector 4 includes: at least two first Connecting plate 5, and the second connecting plate 6 that connects adjacent described first connecting plate 5; Solidly connected; the steel floor 1 ...

Embodiment 2

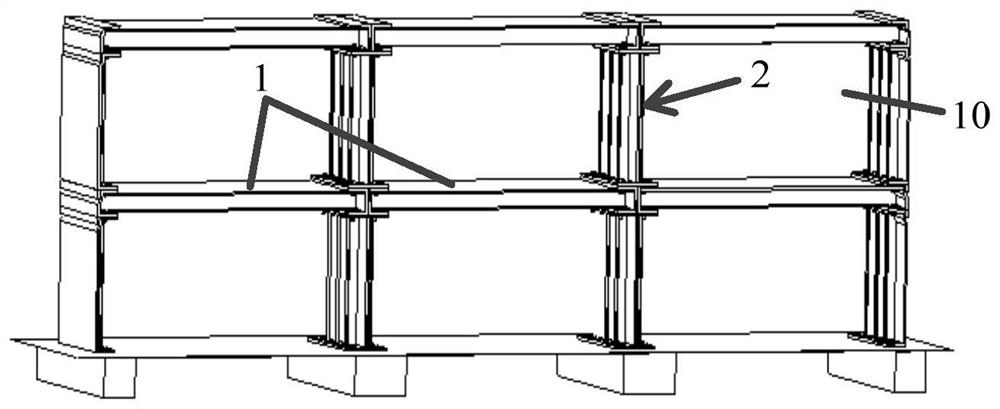

[0057] A box-slab steel structure building, such as figure 2 As shown, it includes: a vibration-damping connection structure, the I-shaped connection structure is arranged on the roof position and the middle layer position of the box-slab steel structure building; and the roof plate and the foundation foundation.

[0058] Vibration-absorbing connection structures, such as image 3 and Figure 4 shown, including:

[0059] Steel floor slabs 1, the steel floor slabs 1 are arranged along the horizontal direction, and at least two adjacent steel floor slabs 1 are arranged on the same horizontal plane to form a floor of a box-slab steel structure building;

[0060] A steel support wallboard 2, the steel support wallboard 2 is a plate-shaped support structure arranged along the vertical direction; and the steel support wallboard 2 is fixedly connected to the steel floor 1;

[0061] The I-shaped connection assembly 3, the I-shaped connection assembly 3 is an I-shaped member compos...

Embodiment 3

[0064] A construction method for a vibration-damping connection structure, comprising the following steps:

[0065] S1, prefabricated steel floor slab 1, steel support wall panel 2 and I-shaped connection component 3 in the factory;

[0066] S2, prefabricating the steel floor 1 to the I-shaped connection assembly 3 in the factory;

[0067] S3, filling the vibration-damping filling part 7 in the accommodating space surrounded by the adjacent second connecting plate 6 and the connecting end 9 of the supporting wall plate, and the I-shaped member is connected to the assembly through a thread 8. Fasten the steel floor slab 1 and the steel support wall panel 2 together to build a box-slab steel structure building.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com