Positive pole piece, preparation method thereof and lithium ion battery

A technology for lithium ion batteries and positive electrode sheets, which is applied in electrode manufacturing, secondary batteries, battery electrodes, etc., can solve the problems of large polarization, lithium deposition capacity decline, and lithium cobalt oxide material capacity limitation, and achieves a reduction in polarization. , Improve the overpotential distribution, improve the effect of lithium precipitation and capacity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

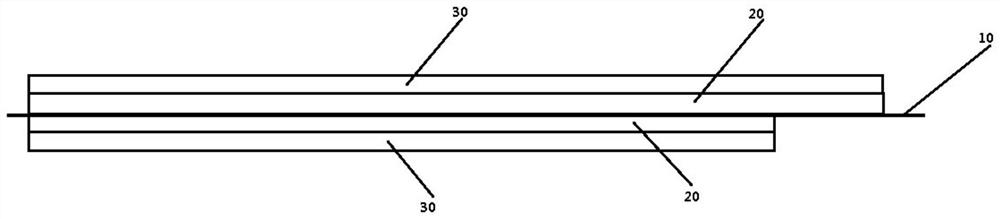

Image

Examples

Embodiment 1

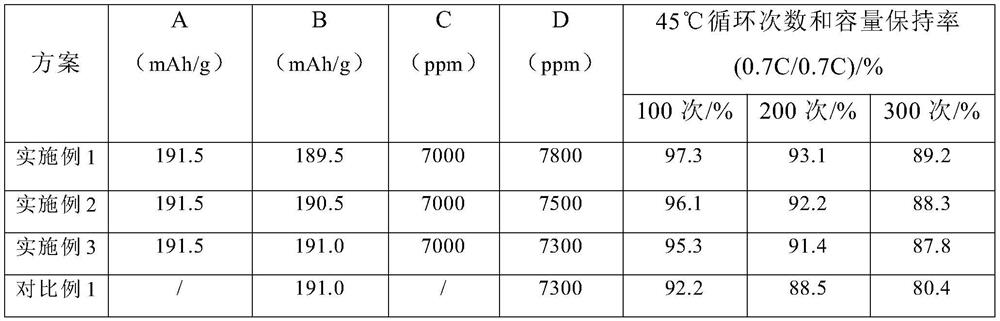

[0032] First, high-voltage lithium cobaltate, conductive carbon black, and polyvinylidene fluoride are mixed according to the mass percentage ratio of 97.2%: 1.5%: 1.3% to obtain the first positive electrode slurry with a gram capacity of high-voltage lithium cobaltate of 189.5mAh / g , the high-voltage lithium cobaltate has a modified element aluminum content of 7800ppm, and the first positive electrode slurry is coated on the long paste surface and the short paste surface of the positive electrode current collector aluminum foil to form the first layer with a thickness of 30um respectively. Active coating; then high-voltage lithium cobaltate, conductive carbon black, and polyvinylidene fluoride are formulated according to the mass percentage ratio of 97.2%: 1.5%: 1.3% to obtain the first high-voltage lithium cobaltate with a gram capacity of 191.5mAh / g Two positive electrode slurries, high-voltage lithium cobaltate with a content of 7000ppm modified element aluminum, the second...

Embodiment 2

[0034] First, high-voltage lithium cobaltate, conductive carbon black, and polyvinylidene fluoride are mixed according to the mass percentage ratio of 97.2%: 1.5%: 1.3% to obtain the first positive electrode slurry with a gram capacity of high-voltage lithium cobaltate of 190.5mAh / g , the high-voltage lithium cobaltate has a modified element aluminum content of 7500ppm, and the first positive electrode slurry is coated on the long paste surface and the short paste surface of the positive electrode current collector aluminum foil to form the first layer with a thickness of 30um respectively. Active coating; then high-voltage lithium cobaltate, conductive carbon black, and polyvinylidene fluoride are formulated according to the mass percentage ratio of 97.2%: 1.5%: 1.3% to obtain the first high-voltage lithium cobaltate with a gram capacity of 191.5mAh / g Two positive electrode slurries, high-voltage lithium cobaltate with a content of 7000ppm modified element aluminum, the second...

Embodiment 3

[0036] First, high-voltage lithium cobaltate, conductive carbon black, and polyvinylidene fluoride are mixed according to the mass percentage ratio of 97.2%: 1.5%: 1.3% to obtain the first positive electrode slurry with a gram capacity of high-voltage lithium cobaltate of 191.0mAh / g , the high-voltage lithium cobaltate has a modified element aluminum content of 7300ppm, and the first positive electrode slurry is coated on the long paste surface and the short paste surface of the positive electrode current collector aluminum foil to form the first layer with a thickness of 30um respectively. Active coating; then high-voltage lithium cobaltate, conductive carbon black, and polyvinylidene fluoride are formulated according to the mass percentage ratio of 97.2%: 1.5%: 1.3% to obtain the first high-voltage lithium cobaltate with a gram capacity of 191.5mAh / g Two positive electrode slurries, high-voltage lithium cobaltate with a content of 7000ppm modified element aluminum Al, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com