Solid electrolyte film and preparation method and application thereof

A technology of solid electrolyte and electrolyte, which is applied in the direction of circuits, electrical components, secondary batteries, etc., can solve the problems of uncontrollable film width and thickness, difficult manufacturing process of solid electrolyte film, unstable electrochemical performance, etc., and achieve good biological performance. Effect of compatibility and degradability, good electrochemical stability, and good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

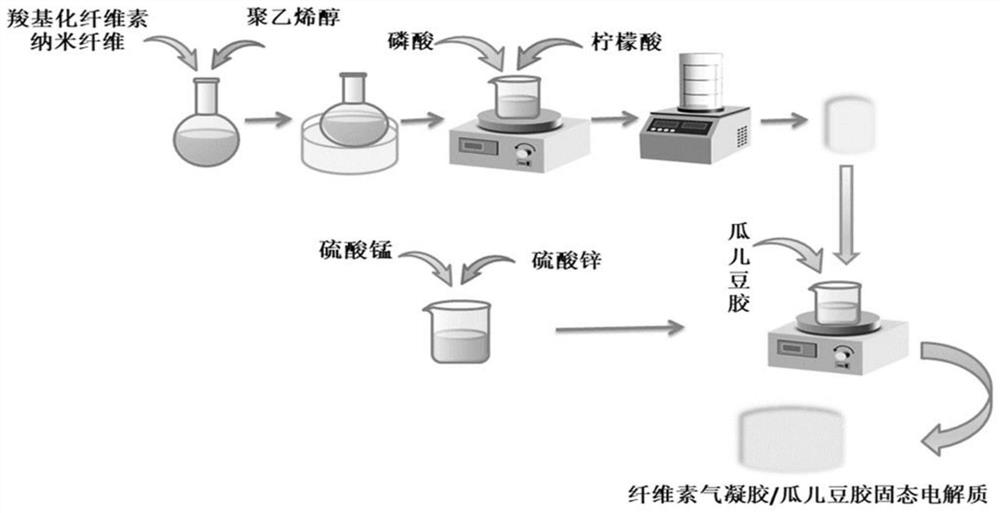

[0042] Step 1, preparation of cellulose airgel: add 20 g of carboxylated cellulose nanofibers to 60 mL of deionized water, then add 0.3 g of polyvinyl alcohol, and place in a constant temperature oil bath at 95°C for 2 hours. After the solution is cooled, quickly add 0.5g of citric acid and 0.5mL of phosphoric acid, and stir until uniform without lumps. Pour the uniform solution into a mold and put it in a refrigerator to freeze at -18°C for 2 hours, and finally freeze-dry it at -45°C and 20 Pa for 48 hours to obtain the cellulose airgel.

[0043] Step 2, preparation of colloidal guar gum electrolyte: ZnSO 4 (AR grade, Sigma) and MnSO 4 (AR grade, Sigma) was added to deionized water and stirred evenly, and ultrasonically removed air bubbles to obtain 10 mL of ZnSO with a concentration of 2 mol / L 4 and 0.1mol / LMnSO 4 mixed solution. Pour 0.6 g of guar gum into the mixed solution while stirring and mix evenly to obtain a colloidal guar gum electrolyte.

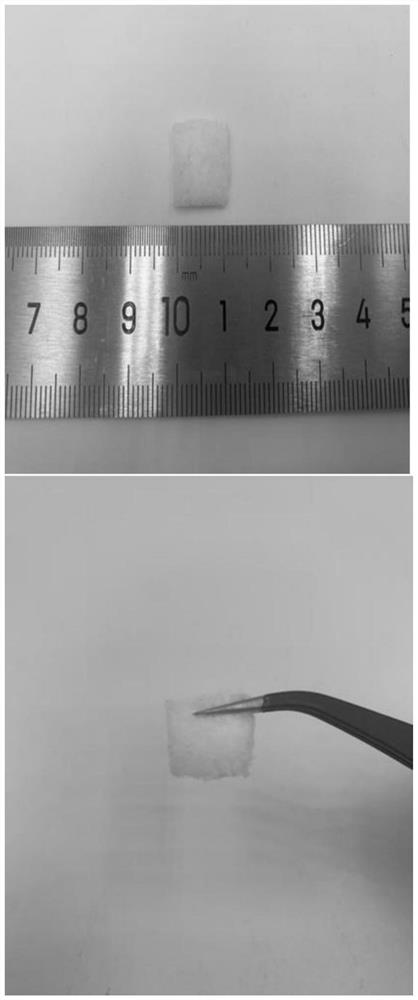

[0044]Step 3, prepa...

Embodiment 2

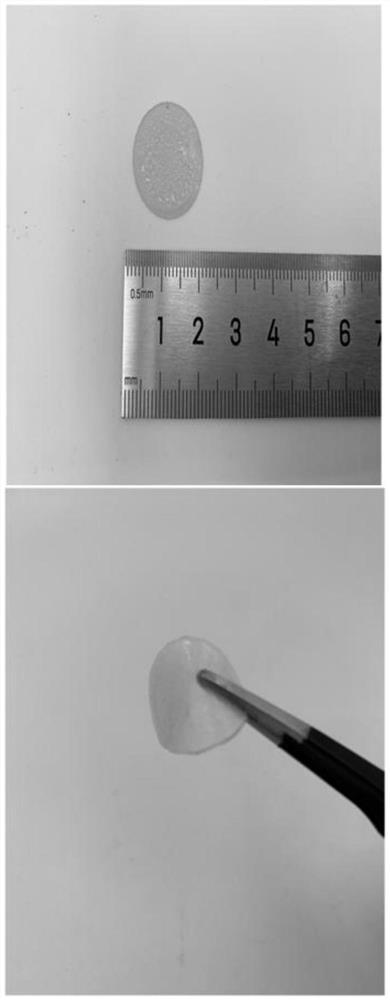

[0055] Same as Example 1, the difference is that step 3 is specifically: inject the colloidal guar gum electrolyte into the cellulose airgel using a syringe, fully mix (at this time, it is in a solid-liquid mixed state), and level it out with a medicine spoon. Spread it on a watch glass to form a film, and dry it to the desired humidity to obtain a solid electrolyte. Cut it into various sizes according to requirements, such as 1cm*1cm*0.06cm, to obtain a solid electrolyte film.

[0056] Results: The solid electrolyte film prepared in this example has no obvious difference from Example 1.

Embodiment 3

[0058] Same as Example 1, the difference is that step 3 is specifically: inject the colloidal guar gum electrolyte into the cellulose airgel using a syringe, then put the mixture (solid-liquid mixed state) into a beaker and stir until uniform Then pour it into a petri dish and spread it into a film to obtain a solid electrolyte. Cut it into various sizes according to requirements, such as 1cm*1cm*0.06cm, to obtain a solid electrolyte film.

[0059] Results: The solid electrolyte film prepared in this example has no obvious difference from Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stress | aaaaa | aaaaa |

| Stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com