Polypyrrole/polyvinylidene fluoride composite film with sandwich structure, and preparation method thereof

A technology of polyvinylidene fluoride and composite film, which is applied in chemical instruments and methods, conjugated synthetic polymer artificial filaments, synthetic resin layered products, etc., can solve the problems of low breakdown strength and decreased breakdown strength, etc. Achieve the effects of improving breakdown strength, improving dielectric properties, and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

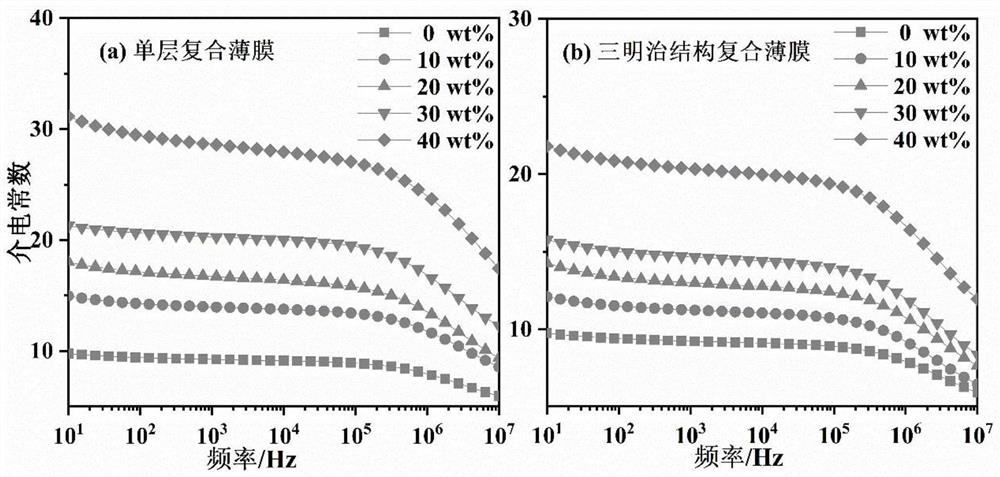

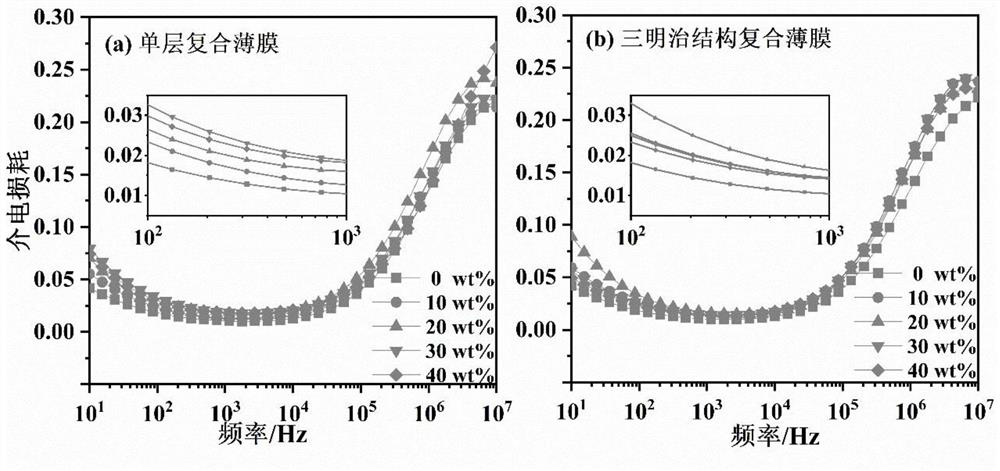

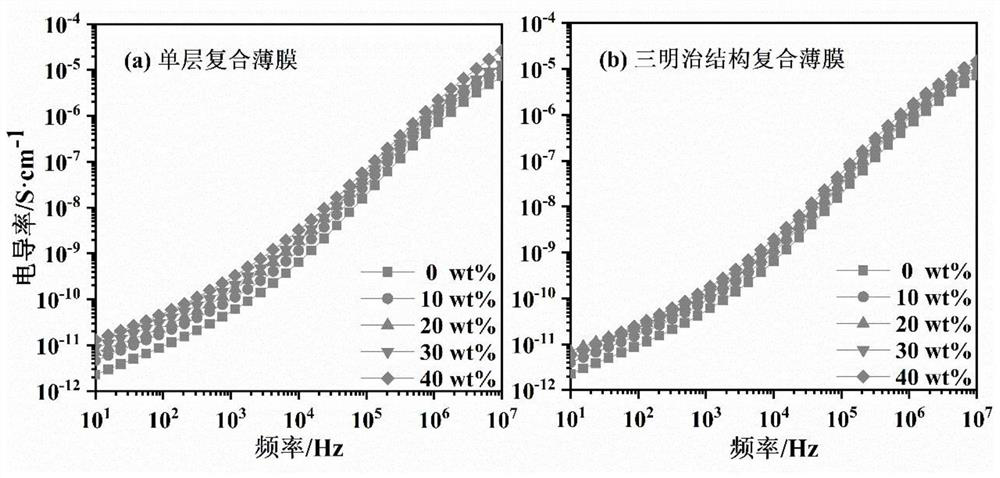

[0030] Embodiment 1. In this implementation, the sandwich structure polypyrrole / polyvinylidene fluoride composite film is divided into three layers, the upper layer and the lower layer are polyvinylidene fluoride films, and the middle layer is a doped polypyrrole / polyvinylidene fluoride composite film.

[0031] Wherein, the content of doped polypyrrole doped in the middle layer accounts for 10wt%, 20wt%, 30wt%, and 40wt% of the middle layer polyvinylidene fluoride respectively;

[0032] The doped polypyrrole is titanium dioxide doped polypyrrole, wherein the content of polypyrrole is 5wt.%, and the content of titanium dioxide is 95wt.%.

[0033] The polyvinylidene fluoride films of the upper and lower layers were prepared by casting film. Put 20g of polyvinylidene fluoride and 120mL N,N dimethylformamide in a three-necked flask, heat and stir at 50°C for 2h, and the obtained Put the glue solution in a vacuum drying oven to evacuate to remove air bubbles, then spread the glue s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com