A fatty acid/sebs stretchable composite film with enhanced triboelectric output, its preparation method and application

A fatty acid, composite membrane technology, applied in triboelectric generators, applications, chemical instruments and methods, etc., can solve problems such as poor triboelectric performance, achieve excellent flexibility, expand practical application fields, and easily achieve large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

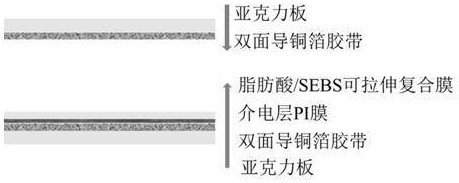

[0032] A method for preparing a fatty acid / SEBS stretchable composite film with enhanced triboelectric output, comprising the following steps:

[0033] 1) Dissolve 4 g of hydrogenated styrene-butadiene block copolymer (SEBS) in 16 g of solvent toluene, wherein the mass fraction of SEBS is 20 wt.%; then add 0.02 g of oleic acid to the above solution; mix After being uniform, the casting solution for preparing the oleic acid / SEBS stretchable composite film is obtained;

[0034] Wherein, the content of oleic acid is 0.5 wt.% of SEBS quality;

[0035] 2) A 1000 μm squeegee rod was used to scrape a film on a glass substrate, and after drying at room temperature, an oleic acid / SEBS stretchable composite film with a thickness of about 350 μm was obtained.

Embodiment 2

[0037] A method for preparing a fatty acid / SEBS stretchable composite film with enhanced triboelectric output, comprising the following steps:

[0038] 1) Dissolve 3 g of SEBS in 17 g of solvent toluene, wherein the mass fraction of SEBS is 15 wt.%; then add 0.06 g of n-decanoic acid to the above solution; mix well to prepare n-decanoic acid / SEBS Casting solution for stretching composite film;

[0039] Wherein, the content of n-decanoic acid is 2.0 wt.% of SEBS quality;

[0040] 2) Use a 500 μm squeegee bar to draw a film on a glass substrate. After drying at room temperature, a n-decanoic acid / SEBS stretchable composite film with a thickness of about 165 μm is obtained.

Embodiment 3

[0042] A method for preparing a fatty acid / SEBS stretchable composite film with enhanced triboelectric output, comprising the following steps:

[0043] 1) Dissolve 5 g of SEBS in 15 g of solvent toluene, wherein the mass fraction of SEBS is 25 wt.%; then add 0.075 g of stearic acid to the above solution; after mixing evenly, the stearic acid / SEBS can be prepared Casting solution for stretching composite film;

[0044] Wherein, the content of stearic acid is 1.5 wt.% of SEBS quality;

[0045] 2) Use a 250 μm squeegee bar to draw a film on a glass substrate, and after drying at room temperature, a stearic acid / SEBS stretchable composite film with a thickness of about 100 μm is obtained.

PUM

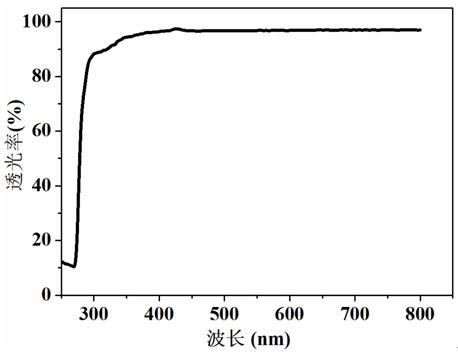

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com