Lightweight artificial quartz stone and production process thereof

A technology of artificial quartz stone and production process, applied in the direction of hydraulic material layered products, biocides, layered products, etc., can solve the problems of uneven distribution of lightweight slurry, poor stone stability, uneven distribution of lines, etc. , to achieve the effect of improving the weight advantage, reducing the overall density and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

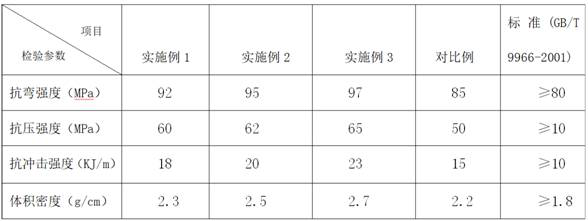

Examples

Embodiment 1

[0029] In the embodiment of the present invention, a lightweight artificial quartz stone is jointly formed by artificial board prefabricated materials and lightweight layer prefabricated materials.

[0030] Among them, the artificial board prefabricated material is composed of the following components by weight: 100-150 parts of white cement, 20-90 parts of silica powder, 200-300 parts of quartz chips, 50-100 parts of stone aggregate, 30-36 parts of water 1.5-3 parts of water reducer, 70-80 parts of resin, 5-10 parts of color paste, 0.1-0.2 parts of curing agent;

[0031] The lightweight layer preform consists of the following components by weight: 6-10 parts of hollow glass microspheres, 20-60 parts of silica powder, and 30-70 parts of resin.

[0032] The processing technology of this artificial quartz stone comprises the following steps:

[0033] S1: Preparation of wood-based panel prefabricated materials, take 100 parts of white cement, 20 parts of silica powder, 200 parts...

Embodiment 2

[0045] In the embodiment of the present invention, a lightweight artificial quartz stone is jointly formed by artificial board prefabricated materials and lightweight layer prefabricated materials.

[0046] Among them, the artificial board prefabricated material is composed of the following components by weight: 100-150 parts of white cement, 20-90 parts of silica powder, 200-300 parts of quartz chips, 50-100 parts of stone aggregate, 30-36 parts of water 1.5-3 parts of water reducing agent, 70-80 parts of resin, 5-10 parts of color paste, 0.1-0.2 parts of curing agent.

[0047] The lightweight layer preform consists of the following components by weight: 6-10 parts of hollow glass microspheres, 20-60 parts of silica powder, and 30-70 parts of resin.

[0048] The processing technology of this artificial quartz stone comprises the following steps:

[0049] S1: Preparation of wood-based panel prefabricated materials, take 130 parts of white cement, 70 parts of silica powder, 25...

Embodiment 3

[0057] In the embodiment of the present invention, a lightweight artificial quartz stone is jointly formed by artificial board prefabricated materials and lightweight layer prefabricated materials.

[0058] Among them, the artificial board prefabricated material is composed of the following components by weight: 100-150 parts of white cement, 20-90 parts of silica powder, 200-300 parts of quartz chips, 50-100 parts of stone aggregate, 30-36 parts of water 1.5-3 parts of water reducing agent, 70-80 parts of resin, 5-10 parts of color paste, 0.1-0.2 parts of curing agent.

[0059] The lightweight layer preform consists of the following components by weight: 6-10 parts of hollow glass microspheres, 20-60 parts of silica powder, and 30-70 parts of resin.

[0060] The processing technology of this artificial quartz stone comprises the following steps:

[0061] S1: Preparation of wood-based panel prefabricated materials, take 150 parts of white cement, 90 parts of silica powder, 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com