Preparation method of sodium alginate-carboxymethyl cellulose gel actuating membrane

A technology of carboxymethyl cellulose and sodium alginate, which is applied in the field of preparation of bionic artificial muscle actuation membranes, can solve problems such as poor biodegradability and biocompatibility, and achieves simple preparation process, improved durability, and membrane formation. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

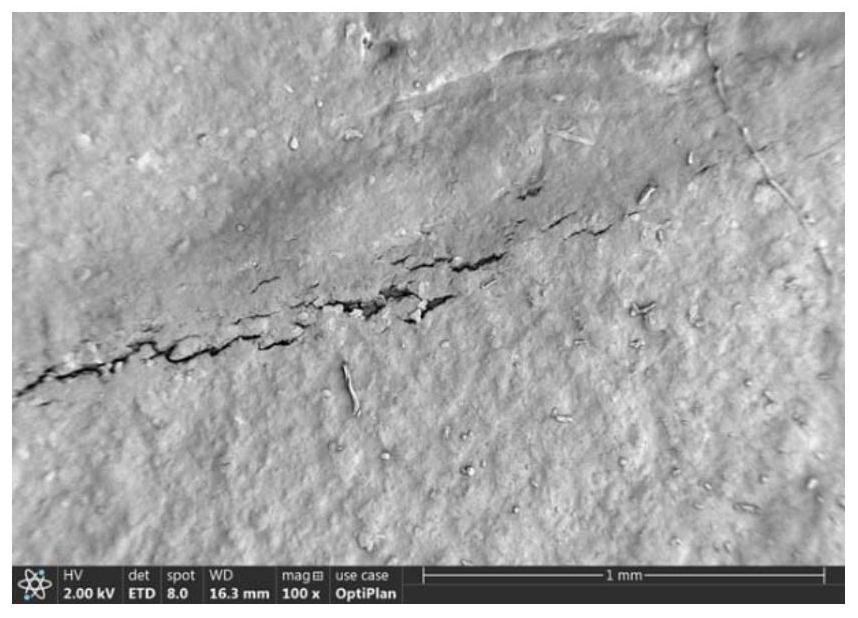

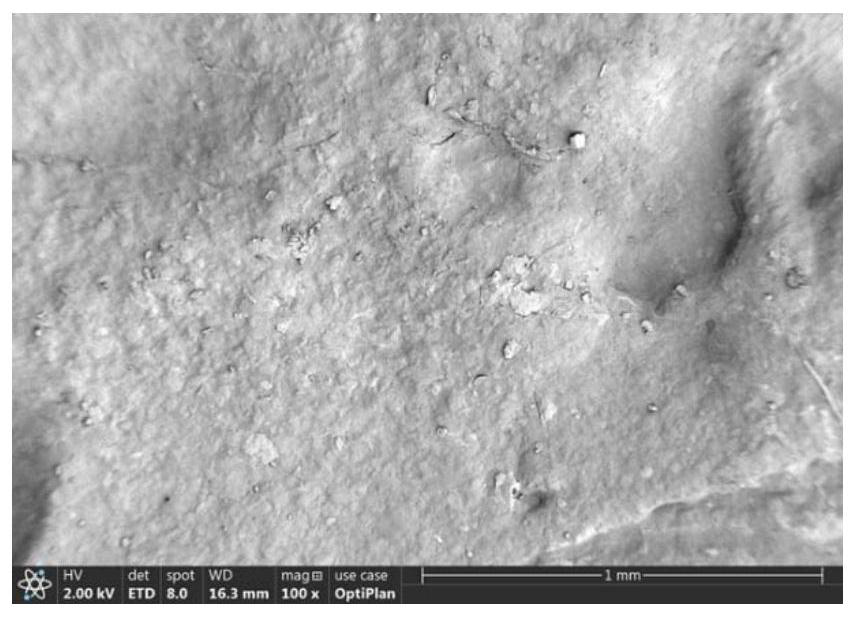

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] The invention is a method for preparing a sodium alginate-carboxymethylcellulose gel actuated film by freeze-drying, the main process of which is as follows:

[0026] Using sodium alginate and carboxymethyl cellulose as the main materials, an actuation membrane suitable for biogel artificial muscles was prepared. The preparation process mainly included the preparation of sodium alginate solution, sodium alginate-carboxymethyl Preparation of cellulose solution, defoaming pretreatment, freeze-drying treatment, cutting and storage.

[0027] (1) Preparation of sodium alginate solution

[0028] Start the heating function of the magnetic stirrer, set the temperature to 50°C, use a graduated cylinder to measure 100ml of distilled water and pour it into a 200ml beaker, and place the beaker in a 500ml large beaker with a water temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com