Ammonia gas sensing film formed based on HPTS and hydrotalcite nanosheet, and preparation method thereof

A technology for sensing thin films and nanosheets, applied in chemical instruments and methods, fluorescence/phosphorescence, instruments, etc., can solve problems such as time-consuming, slow response time, and high cost, and achieve improved optical performance, thermal stability, and good light transmission and film-forming properties, as well as the effects of excellent reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

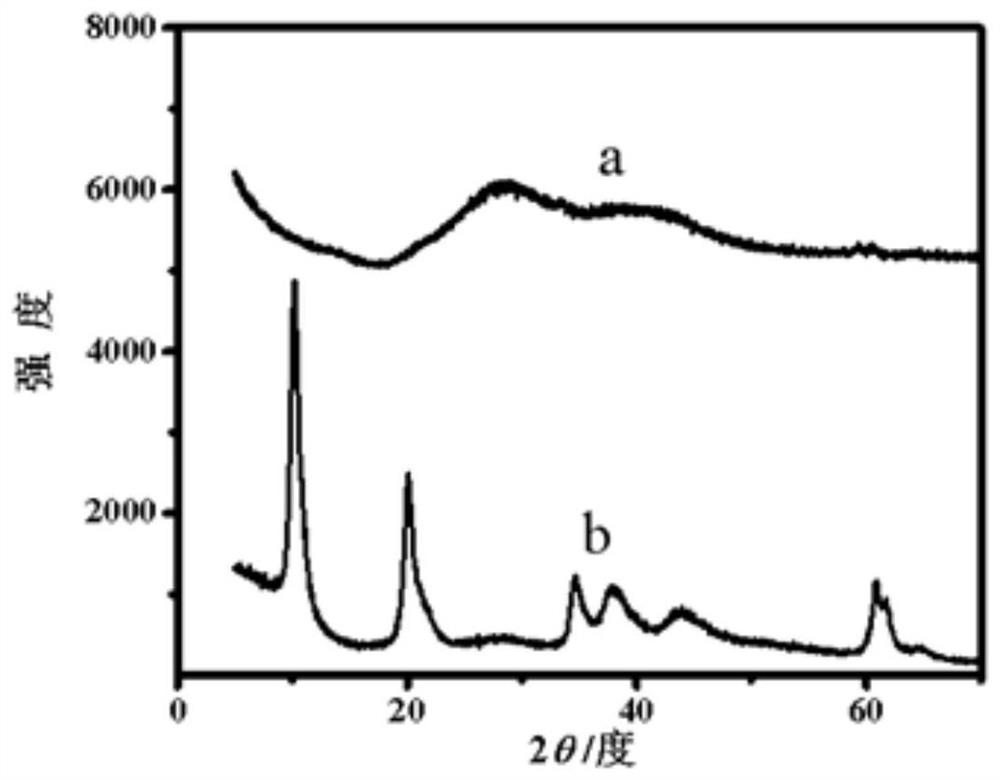

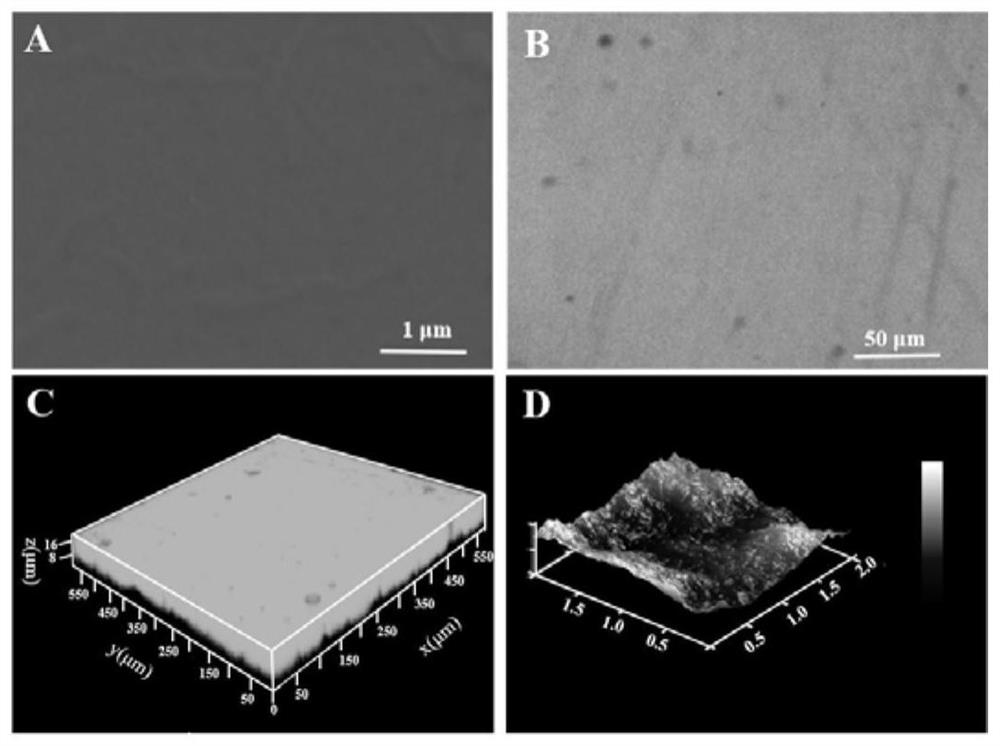

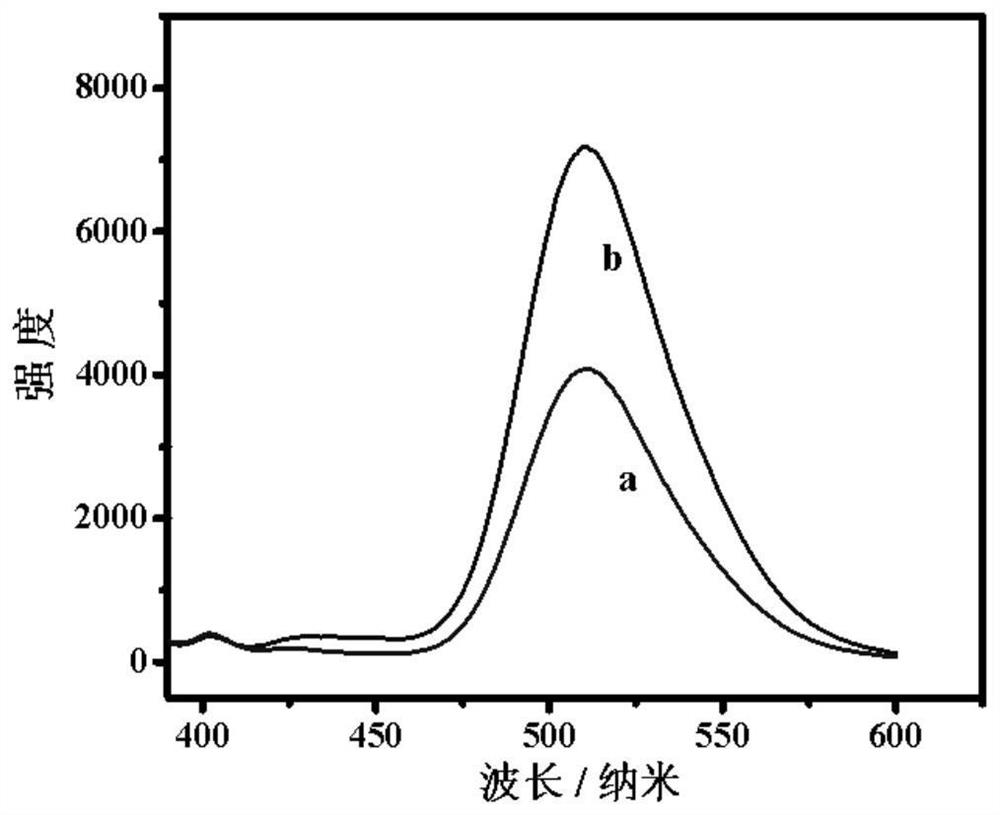

[0021] Step A: Preparation of monolayer hydrotalcite nanosheets

[0022] Hydrotalcite nanosheets were prepared by the double drop method. 0.004mol Mg(NO 3 ) 2 ·6H 2 O and 0.001mol Al(NO 3 ) 3 9H 2 O (the molar ratio is 4:1) is dissolved in the cooled, boiled, N 2 deionized water, made into a mixed salt solution, dissolved in 100mL of water; prepared a NaOH solution with a concentration of 0.25M. NaNO at a concentration of 0.01M 3 Add 100 mL of the solution and 100 mL of N,N dimethylformamide solution with a concentration of 0.01M into a three-necked flask for magnetic stirring to dissolve, and preheat to 80°C. After waiting for the temperature to stabilize, add NaOH solution dropwise to the three-necked flask to adjust the pH=10, then add the mixed salt solution and NaOH solution dropwise to the three-necked flask at the same time to control the pH=10, cool and centrifugally wash after the addition is completed, A colloidal single-layer hydrotalcite nanosheet was obta...

Embodiment 2

[0029] Step A: Preparation of monolayer nanosheet hydrotalcite

[0030] Hydrotalcite nanosheets were prepared by the double drop method. 0.003mol Mg(NO 3 ) 2 ·6H 2 O and 0.001mol Al(NO 3 ) 3 9H 2 O (molar ratio is 3:1) dissolves in cooled, boiled, N 2 , deionized water, made a mixed salt solution and dissolved in 100mL water; prepared a NaOH solution with a concentration of 0.25M. NaNO at a concentration of 0.01M 3 Add 100 mL of the solution and 100 mL of N,N dimethylformamide solution with a concentration of 0.01M into a three-necked flask for magnetic stirring to dissolve, and preheat to 75°C. After waiting for the temperature to be stable, add NaOH solution dropwise to the three-necked flask to adjust the pH=10.5, then add the mixed salt solution and NaOH solution dropwise to the three-necked flask at the same time to control the pH=10, cool and centrifugally wash after the addition is completed, A colloidal single-layer hydrotalcite nanosheet was obtained.

[003...

Embodiment 3

[0036] Step A: Preparation of monolayer nanosheet hydrotalcite

[0037] Hydrotalcite nanosheets were prepared by the double drop method. 0.002mol Mg(NO 3 ) 2 ·6H 2 O and 0.001mol Al(NO 3 ) 3 9H 2 O (mole ratio is 2:1) dissolved in the cooled boiled and passed through N 2 prepared a mixed salt solution in 100mL of deionized water; prepared a NaOH solution with a concentration of 0.25M. NaNO at a concentration of 0.01M 3 Add 100 mL of the solution and 100 mL of N,N dimethylformamide solution with a concentration of 0.01M into a three-neck flask for magnetic stirring to dissolve, and preheat to 70°C. After waiting for the temperature to be stable, add NaOH solution dropwise to the three-necked flask to adjust the pH=10, then add the mixed salt solution and NaOH solution dropwise to the three-necked flask at the same time to control the pH=9.5, cool and centrifugally wash after the addition is completed, A colloidal single-layer hydrotalcite nanosheet was obtained.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com