Mulberry leaf black tea solid beverage preparation method and processing equipment

A technology for mulberry leaf black tea and solid beverages, applied in chemical instruments and methods, tea substitutes, dissolution and other directions, can solve problems such as inconvenience in using black tea, achieve good taste, avoid solvent residue problems, and reduce the intensity of human labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

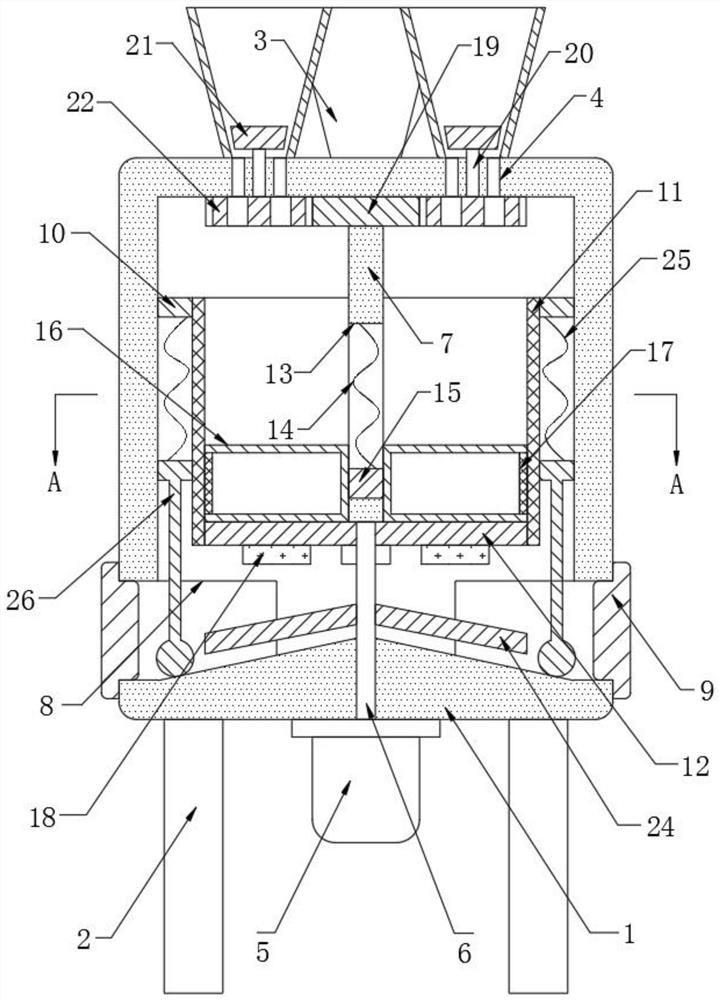

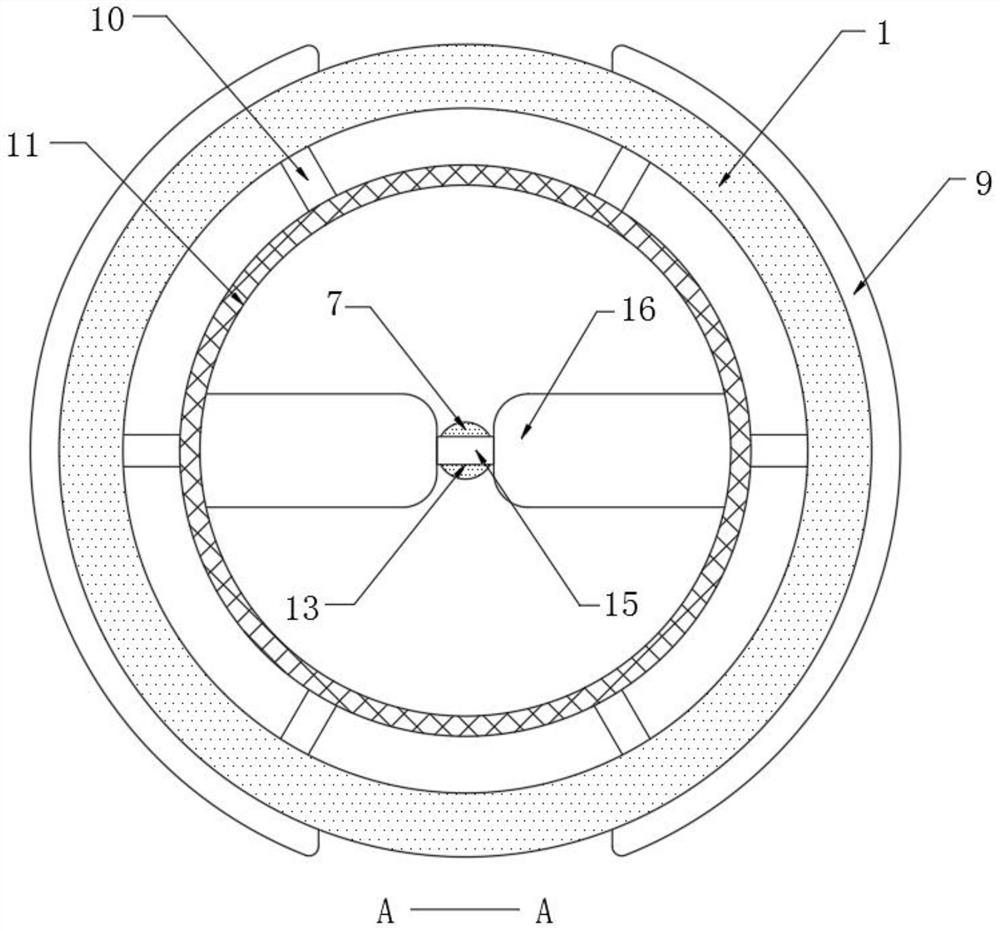

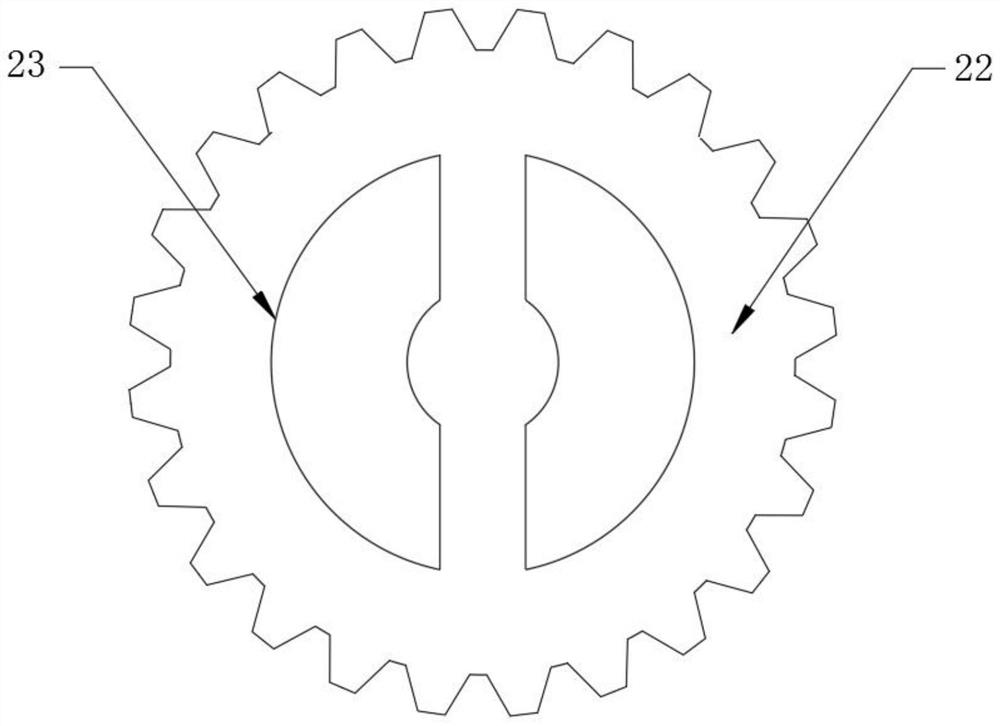

[0037] refer to Figure 1-4 , a method for preparing a solid beverage of mulberry leaf black tea and a processing device thereof, mainly comprising the following processing steps:

[0038] (1) Freeze-drying: firstly, an appropriate amount of mulberry leaf black tea was placed in a vacuum freeze dryer, and dried for 24 hours at a drying temperature of -20° C. and a vacuum of 0.1 MPa to obtain a mulberry leaf black tea freeze-dried product.

[0039] (2) Mechanical pulverization: the freeze-dried mulberry leaf black tea described in step 1 is crushed through a multifunctional pulverizer, and passed through a 100-mesh sieve to obtain mulberry leaf black tea powder.

[0040] (3) Constant temperature extraction: add distilled water twice the mass volume to the mulberry leaf black tea powder described in step 2, extract at a constant temperature for 8 hours at an extraction temperature of 50° C., centrifuge and take the supernatant; repeat the extraction twice and combine the filtra...

Embodiment 2

[0056] The present embodiment provides a kind of preparation method of mulberry leaf black tea solid beverage, mainly comprises the following processing steps:

[0057] (1) Freeze-drying: firstly, an appropriate amount of mulberry leaf black tea is placed in a vacuum freeze dryer, and dried for 24 hours at a drying temperature of -20° C. and a vacuum degree of 0.1 MPa to obtain a mulberry leaf black tea freeze-dried product.

[0058] (2) Mechanical pulverization: the freeze-dried mulberry leaf black tea described in step 1 is crushed through a multifunctional pulverizer, and passed through a 100-mesh sieve to obtain mulberry leaf black tea powder.

[0059] (3) Constant temperature extraction: add 3 times the mass and volume of distilled water to the mulberry leaf black tea powder described in step 2, extract at a constant temperature for 7 hours at an extraction temperature of 60°C, and take the supernatant after centrifugation; repeat the extraction twice and combine the filt...

Embodiment 3

[0066] The present embodiment provides a kind of preparation method of mulberry leaf black tea solid beverage, mainly comprises the following processing steps:

[0067] (1) Freeze-drying: firstly, an appropriate amount of mulberry leaf black tea is placed in a vacuum freeze dryer, and dried for 24 hours at a drying temperature of -20° C. and a vacuum degree of 0.1 MPa to obtain a mulberry leaf black tea freeze-dried product.

[0068] (2) Mechanical pulverization: the freeze-dried mulberry leaf black tea described in step 1 is crushed through a multifunctional pulverizer, and passed through a 100-mesh sieve to obtain mulberry leaf black tea powder.

[0069] (3) Constant temperature extraction: Add 4 times the mass volume of distilled water to the mulberry leaf black tea powder described in step 2, extract at a constant temperature for 6 hours at an extraction temperature of 65°C, and take the supernatant after centrifugation; repeat the extraction twice and combine the filtrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com