Novel process for co-production of high-quality rice husk-based activated carbon and wet-process sodium silicate

A high-quality technology based on activated carbon, used in silicates, alkali metal silicates, chemical instruments and methods, etc., to achieve the effects of high thermal energy utilization efficiency, low degree of lattice formation, and easy extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

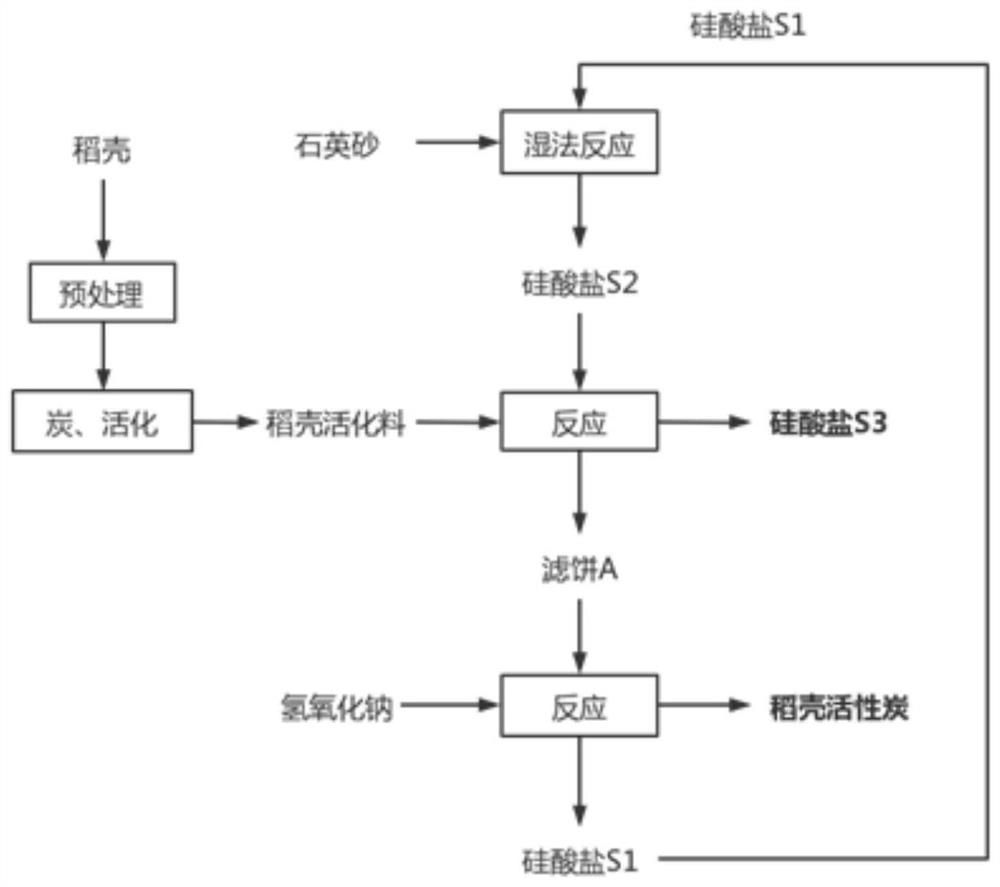

Method used

Image

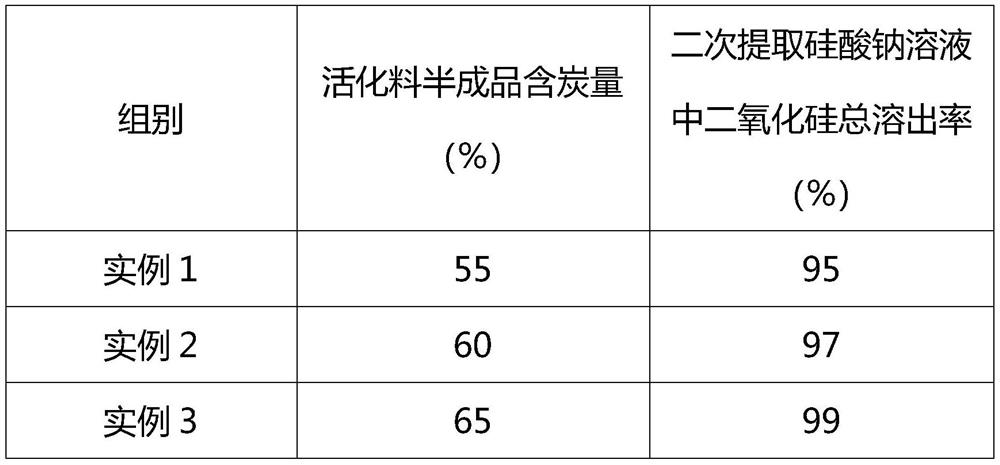

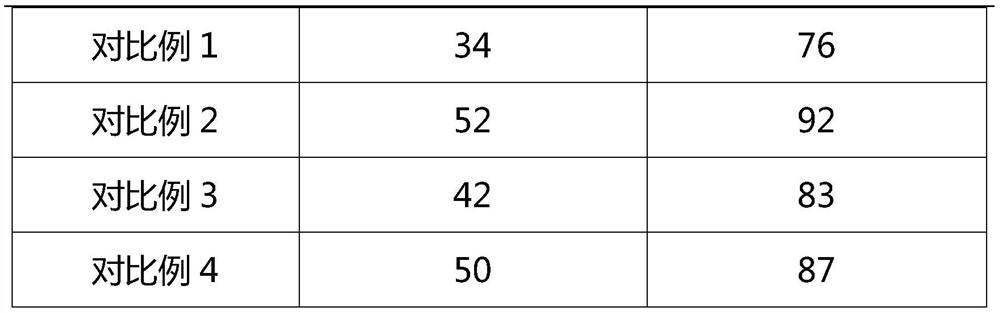

Examples

Embodiment 1

[0034] A new process for the joint production of high-quality rice husk-based activated carbon and wet-process sodium silicate, comprising the following steps:

[0035] A. Rice husk pretreatment:

[0036] The rice husk raw material is screened to remove impurities, such as large specific gravity sand, bricks, metal pieces and other impurities.

[0037] B. Preparation of rice husk activation material:

[0038] Reaction principle: C+H 2 O→CO+H 2

[0039] Rice husks with 12% moisture and 15% ash were put into a carbonization furnace, and a reducing gas at 600°C was introduced for carbonization. The reducing gas came from the high-temperature tail gas of the activation section, and the carbonization time was 2 hours. Use flammable gas anoxic combustion to heat steam to 850°C for activation. The activation time is 2 hours. The steam accounts for 40% of the total activation gas, and the semi-finished activation material is obtained.

[0040] C. Preparation of high modulus sodiu...

Embodiment 2

[0048] A new process for the joint production of high-quality rice husk-based activated carbon and wet-process sodium silicate, comprising the following steps:

[0049] A. Rice husk pretreatment:

[0050] The rice husk raw material is screened to remove impurities, such as large specific gravity sand, bricks, metal pieces and other impurities.

[0051] B. Preparation of rice husk activation material:

[0052] Reaction principle: C+H 2 O→CO+H 2

[0053] Rice husks with 12% moisture and 15% ash were put into a carbonization furnace, and a reducing gas at 600°C was introduced for carbonization. The reducing gas came from the high-temperature tail gas of the activation section, and the carbonization time was 2 hours. Use flammable gas anoxic combustion to heat steam to 900°C for activation. The activation time is 3 hours. The steam accounts for 50% of the total activation gas, and the semi-finished activation material is obtained.

[0054] C. Preparation of high modulus sodiu...

Embodiment 3

[0062] A new process for the joint production of high-quality rice husk-based activated carbon and wet-process sodium silicate, comprising the following steps:

[0063] A. Rice husk pretreatment:

[0064] The rice husk raw material is screened to remove impurities, such as large specific gravity sand, bricks, metal pieces and other impurities.

[0065] B. Preparation of rice husk activation material:

[0066] Reaction principle: C+H 2 O→CO+H 2

[0067] Rice husks with 12% moisture and 15% ash were put into a carbonization furnace, and a reducing gas at 600°C was introduced for carbonization. The reducing gas came from the high-temperature tail gas of the activation section, and the carbonization time was 2 hours. Use flammable gas anoxic combustion to heat the steam to 950°C for activation, the activation time is 4 hours, steam accounts for 60% of the total activation gas, and the semi-finished activation material is obtained.

[0068] C. Preparation of high modulus sodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com