Low-ignition-energy miniature slapper detonator

A shock-blade detonator and low ignition technology, applied in the direction of detonators, offensive equipment, etc., can solve the problems that it is difficult to meet the miniaturization requirements of smart ammunition, the shock-blade detonator is large in size, and the actual volume is limited, so as to improve energy utilization and detonation Low energy, reducing the effect of detonation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below.

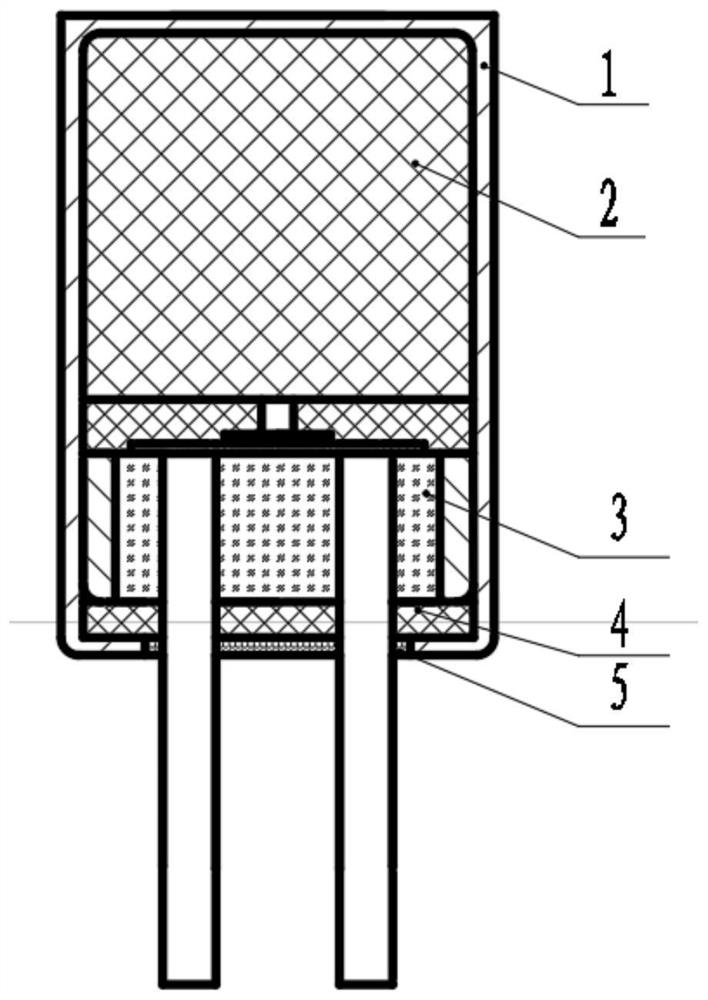

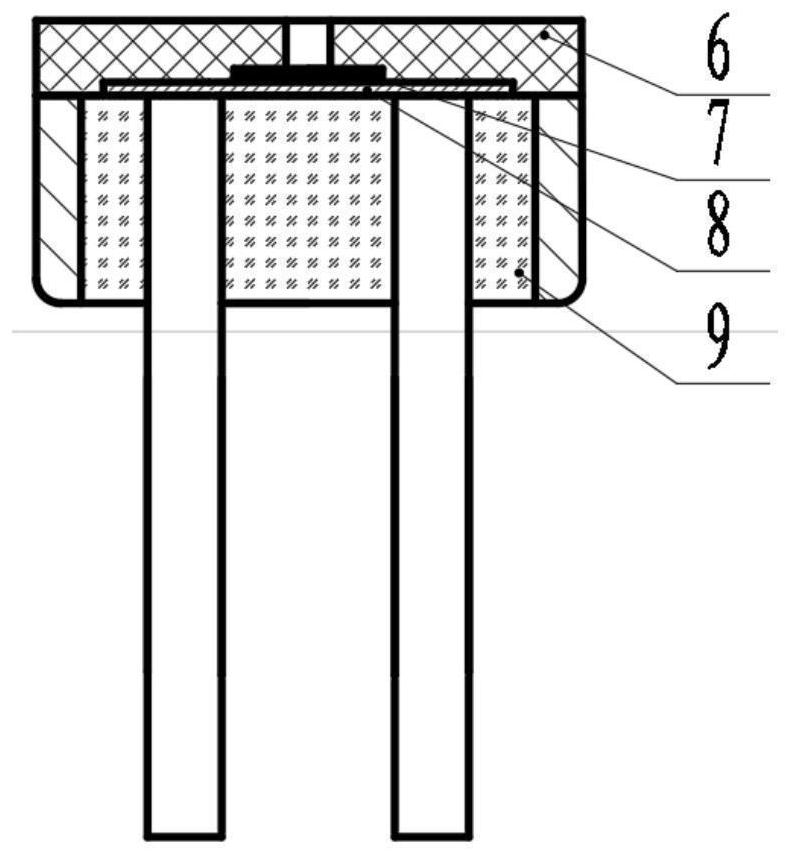

[0016] The present invention proposes a micro-shock plate detonator with low ignition energy, which is mainly composed of a shell 1, a charge 2, a transducer element 3, and a wire breaker 4. The transducer element includes a glass-sealed electrode plug 9, a bridge foil 8, Flyer 7, acceleration chamber 6; the acceleration chamber is provided with a central hole;

[0017] Press-fit the charge (HNS) directly into the casing, the pressure of the charge is 120-140MPa, and the transducer element accelerates the chamber facing the charge and loads it into the casing, the acceleration chamber is in contact with the powder surface, and then installs the splitter 4 to Ensure the distance between the electrode pins of the transducer element, and then use the closing mold to close the mouth, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com