Alkylphenol modified phenolic resin suitable for hot-melt preimpregnation process and preparation method of alkylphenol modified phenolic resin

A technology of phenolic resin and alkylphenol, which is applied in the field of alkylphenol modified phenolic resin and its preparation, can solve the problems of low quality stability, difficulty in balancing material ablation resistance and mechanical properties, etc., to improve mechanical properties, Reduced crosslink density and carbon residue rate, good film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

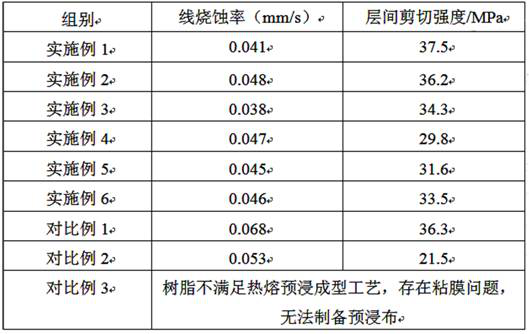

Examples

Embodiment 1

[0037] The alkylphenol-modified phenolic resin suitable for the hot-melt prepreg process described in this embodiment, its preparation raw materials are: phenol, aldehyde and alkaline catalyst;

[0038] Wherein, the phenol is composed of 8% tert-butylphenol by mass percentage, 90% phenol, and 2% bisphenol A; the aldehyde is formaldehyde; the basic catalyst is barium hydroxide;

[0039] The molar ratio of phenol to aldehyde is 1:1.3; the mass of basic catalyst accounts for 1.2% of the total mass of phenol.

[0040] The preparation method of the alkylphenol-modified phenolic resin suitable for the hot-melt prepreg process described in this embodiment comprises the following steps:

[0041] S1. According to the amount of raw materials selected above, add the above-mentioned mixed phenol into the reaction vessel, drop formaldehyde solution into the melted mixed phenol under stirring, heat and stir evenly, add catalyst barium hydroxide to it after cooling;

[0042] S2. The mixture...

Embodiment 2

[0045] The alkylphenol-modified phenolic resin suitable for the hot-melt prepreg process described in this embodiment, its preparation raw materials are: phenol, aldehyde and alkaline catalyst;

[0046] Wherein, phenol is composed of 13% tert-butylphenol, 20% bisphenol A, and 67% phenol by mass percentage; the aldehyde is formaldehyde; the basic catalyst is ammonia;

[0047] The molar ratio of phenol to aldehyde is 1:1.4; the mass of basic catalyst accounts for 1.2% of the total mass of phenol.

[0048] The preparation method of the alkylphenol-modified phenolic resin suitable for the hot-melt prepreg process described in this embodiment comprises the following steps:

[0049] S1. According to the amount of raw materials selected above, add the above-mentioned mixed phenol into the reaction vessel, drop formaldehyde solution into the melted mixed phenol under stirring, heat and stir evenly, add catalyst ammonia water to it after cooling;

[0050] S2. The mixture in step S1 is h...

Embodiment 3

[0053] The alkylphenol-modified phenolic resin suitable for the hot-melt prepreg process described in this embodiment, its preparation raw materials are: phenol, aldehyde and alkaline catalyst;

[0054] Wherein, phenol is composed of 13% tert-butylphenol and 87% phenol by mass percentage; aldehyde is paraformaldehyde; basic catalyst is triethylamine;

[0055] The molar ratio of phenol to aldehyde is 1:1.3; the mass of basic catalyst accounts for 1% of the total mass of phenol.

[0056] The preparation method of the alkylphenol-modified phenolic resin suitable for the hot-melt prepreg process described in this embodiment comprises the following steps:

[0057] S1. According to the amount of raw materials selected above, add the above-mentioned mixed phenol into the reaction vessel, put the paraformaldehyde solution into the melted mixed phenol under stirring, heat and stir evenly, and then add the catalyst triethylamine to it after cooling down ;

[0058] S2. The mixture in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com