Method for regulating and controlling work hardening capability of amorphous/amorphous nano multilayer film

A nano-multilayer, work-hardening technology, applied in metal material coating process, coating, ion implantation plating and other directions, can solve the problems of reducing the strength of amorphous alloys, difficult to achieve, etc., to achieve simple operation, easy implementation, interface clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

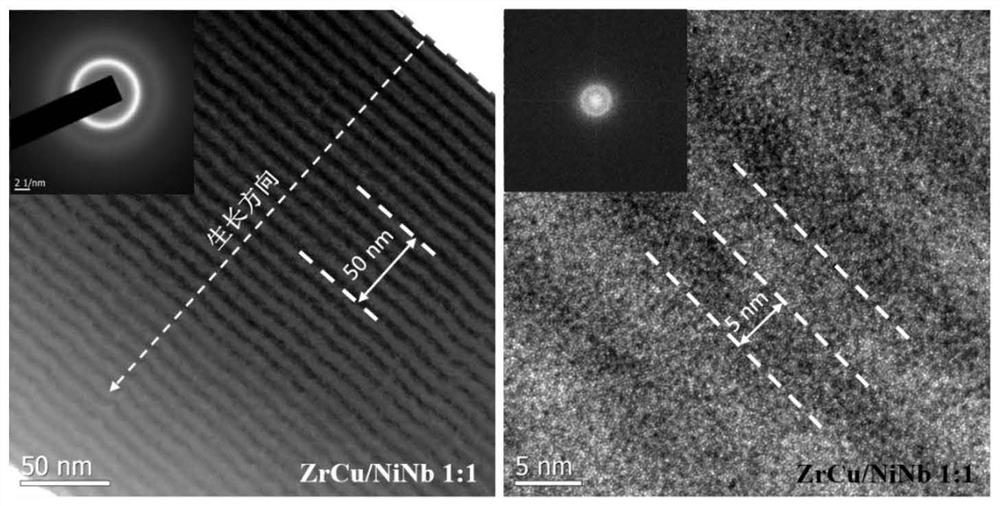

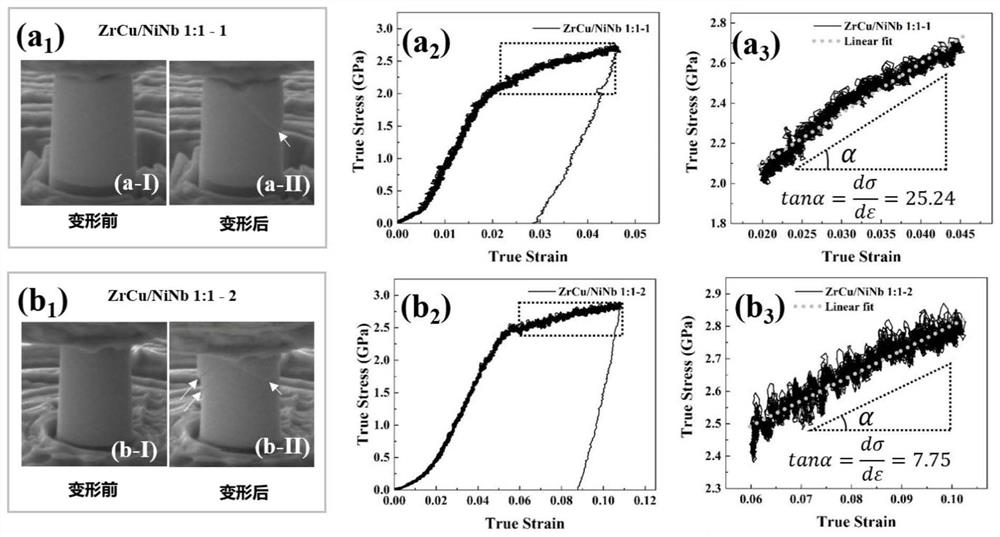

[0026] The present invention is a method for adjusting and controlling the work hardening ability of amorphous / amorphous nano-multilayer film. In the magnetron sputtering process, a slow rate deposition process is adopted to change the Zr by controlling the sputtering time. 50 Cu 50 layer and Ni 50 Nb 50 The thickness of the single layer of the layer, Zr with different work hardening ability is obtained 50 Cu 50 / Ni 50 Nb 50 multilayer film. Compared with Zr 50 Cu 50 layer and Ni 50 Nb 50 The multilayer films with layer thicknesses of 15 ± 1.2 nm and 5 ± 0.4 nm were significantly improved. It specifically includes the following steps:

[0027] 1) The single-sided polished single-crystal silicon (100) substrate is ultrasonically cleaned with acetone, alcohol and distilled water respectively, then dried by a hair dryer, placed on the substrate stage of an ultra-high vacuum magnetron sputtering equipment, and prepared for coating; In the best embodiment of the present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com