Polyester dyeing process

A process and polyester technology, applied in the field of polyester dyeing process, can solve the problems of poor dyeability of polyester fibers, cumbersome, and increase the burden of sewage treatment, and achieve the effect of saving energy consumption, saving energy and production costs, and saving work content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Noodle type: warp knitted jacquard sandwich jacquard mesh;

[0032] Fabric specification: 250g / m 2

[0033] Yarn Composition: 100% Polyester

[0034] Fabric color: black;

[0035] Fabric dyeing process:

[0036] First, pre-treat the fabric. The process is as follows: put the fabric in the dye vat and add water, then heat up to 80°C at 2°C / L, add pre-treatment additives in the water and continue to heat up to 110°C, then treat for 10 minutes, then Drainage; the former assistant auxiliary agent includes refining agent 0.6g / L, sodium hydroxide 2.5g / L, sodium carbonate 2.5g / L, sodium hydrosulfite 1.2g / L, degreasing agent 1.2g / L; pretreatment ends Afterwards, the temperature is lowered and the liquid is drained, and then the dyeing process is carried out;

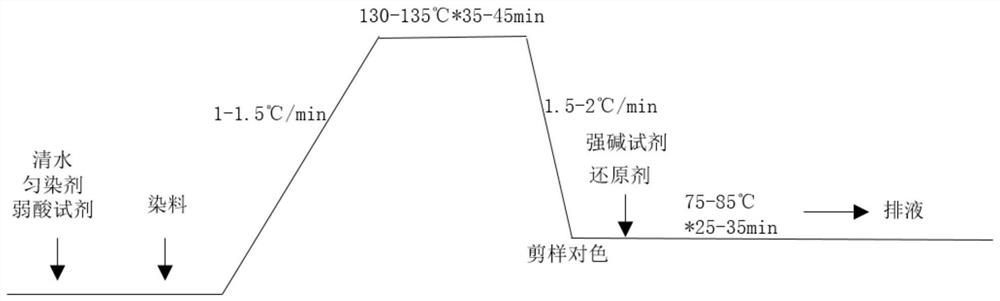

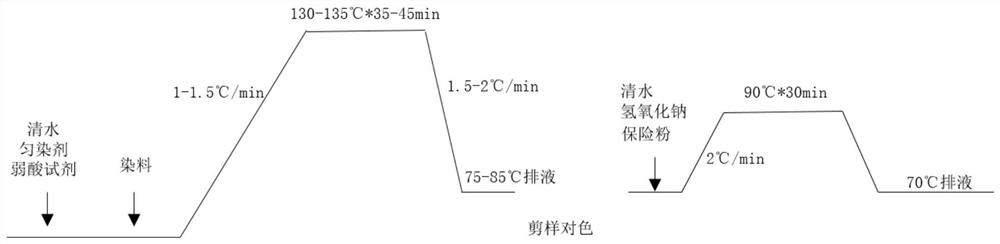

[0037] Add clear water to the dyeing vat, the bath ratio is 1:6, then add leveling agent 1.1g / L, glacial acetic acid 1.1g / L, add 5% disperse dye (owf) after the dyeing vat runs at room temperature for 10 minutes, and...

Embodiment 2

[0039] Surface type: weft-knitted double-sided fabric;

[0040] Fabric specification: 200g / m 2

[0041] Yarn composition: 100% polyester;

[0042] Fabric color: gray;

[0043] Fabric dyeing process:

[0044] First, pre-treat the fabric. The process is as follows: put the fabric in the dye vat and add water, then raise the temperature to 85°C at 2°C / L, add pre-treatment additives in the water and continue to heat up to 110°C, then treat for 10 minutes, then Drainage; the former assistant auxiliary agent includes refining agent 0.8g / L, sodium hydroxide 3g / L, sodium carbonate 2.5g / L, hydrosulfite 1.5g / L, degreasing agent 1.5g / L; Cool down and drain, and then carry out the dyeing process;

[0045]Add clear water to the dyeing vat, the bath ratio is 1:8, then add leveling agent 1.3g / L, glacial acetic acid 1.0g / L, add 4% (owf) disperse dye after the dyeing vat runs at room temperature for 10 minutes, and add 4% (owf) of disperse dye at 1°C / L Raise the temperature to 130°C and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com