Test method for simulating iron bacterial corrosion in water environment

A test method and iron bacteria technology, applied in the field of corrosion, can solve the problems of inability to simulate corrosion products and metabolites, and do not consider the influence of microbial film marine environmental factors, and achieve the effect of facilitating in-situ observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of pure SA solution is to add SA into deionized water at 60°C, stir to dissolve it, and let it stand to remove air bubbles before use. Composite SA solution consists of Fe(OH) 3 The powder is prepared by blending with SA solution. The preparation method of composite SA solution is: Fe(OH) 3 Add the powder into the SA solution, disperse it with a high-speed dispersing homogenizer for 15 minutes, and treat it in an ultrasonic cleaner for 5 minutes as a treatment cycle, with a total of 6 cycles.

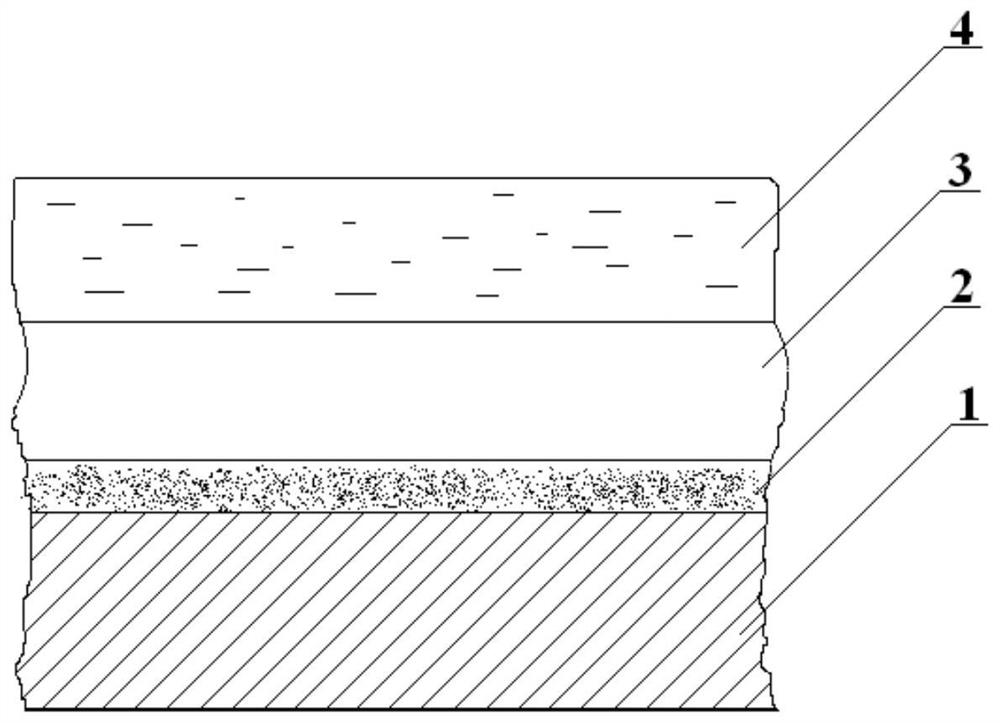

[0027]The preparation method of the simulated microbial film is as follows: apply a 200 μm thick composite SA solution film on the surface of the sample with a wire bar coater or a film applicator conforming to the national standard GB / T 1727, and spray a gel agent on the surface of the liquid film to make the composite SA solution Membrane gel, according to the research needs, the same method can be used to prepare several layers of composite SA gel memb...

Embodiment 1

[0029] Evaluation of IOB corrosion resistance of steel materials based on weight loss method

[0030] The concentration of SA solution is 3wt%. Fe(OH) in composite SA solution 3 The amount of addition is 0.5mol / L; when the simulated microbial film is prepared, the CaCl in the gel 2 The concentration is 8 wt%. Three layers of composite sodium alginate gel films were prepared on the steel substrate, and five layers of pure sodium alginate gel films were prepared on the surface of the composite sodium alginate gel films.

[0031] The test solution is a 3.5wt% NaCl aqueous solution, in which ferric chloride and H 2 o 2 , Fe 3+ Concentration is 0.2mol / L, H 2 o 2 The concentration is 0.05mmol / L; the simulated seawater velocity is 5m / s, and the temperature is 25°C.

[0032] After the sample is soaked in the test solution, the Fe in the test solution 3+ and H 2 o 2 decomposed O 2 The pure SA gel film and the composite SA gel film diffuse to the steel substrate and particip...

Embodiment 2

[0035] Electrochemical Study on IOB Corrosion Process of Iron and Steel Materials

[0036] The concentration of SA solution is 3wt%. Fe(OH) in composite SA solution 3 The added amount is 0.3mol / L. When simulating microbial film preparation, the CaCl in the gel 2 The concentration is 6 wt%. Two layers of composite sodium alginate gel films were prepared on the steel substrate, and three layers of pure sodium alginate gel films were prepared on the surface of the composite sodium alginate gel films.

[0037] The test solution is deionized water to which ferric sulfate and H 2 o 2 , Fe 3+ Concentration is 0.1mol / L, H 2 o 2 The concentration is 0.4mmol / L. The sample was used as the working electrode, and the test solution was used as the electrolyte, and the electrochemical impedance test was performed using an electrochemical workstation. The test temperature is 25°C and the scan range is 10 -2 -10 5 Hz, the amplitude of the sine wave potential is 20mV.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com