Composite sterilization corrosion inhibitor for oil field and preparation method of composite sterilization corrosion inhibitor

A composite corrosion inhibitor technology, applied in the fields of botanical equipment and methods, biocides, chemical instruments and methods, etc., can solve the problems of decreased efficacy, unsatisfactory, and heavy operation workload, and achieves a high level of quality. Capacitive permeability, convenient on-site dosing, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

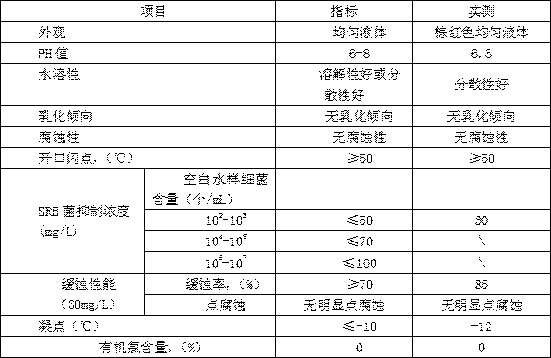

Embodiment 1

[0019] A kind of preparation method of oil field compound type bactericidal corrosion inhibitor, concrete steps are as follows:

[0020] Step 1: Put 25kg of oleic acid, 10kg of naphthenic acid and 18kg of diethylenetriamine into the reactor, raise the temperature to 160 degrees Celsius, turn on the condenser to cool the water, react for 2 hours, observe the water out, during which water should be formed and condensed take over;

[0021] In step 2, the reaction kettle is heated to 190 degrees Celsius, reacted for 2 hours, and then heated to 230 degrees Celsius, and after 4 hours of reaction, there should be basically no more water at this time, and the temperature is lowered to 50 degrees Celsius;

[0022] Step 3, add methanol 30kg again in the reactor, and the reactor was reacted at 42 degrees centigrade for 0.5 hour;

[0023] Step 4, pump 17kg of glacial acetic acid into the dripping tank, slowly drop it, the reaction is an exothermic reaction, control the speed of the dropp...

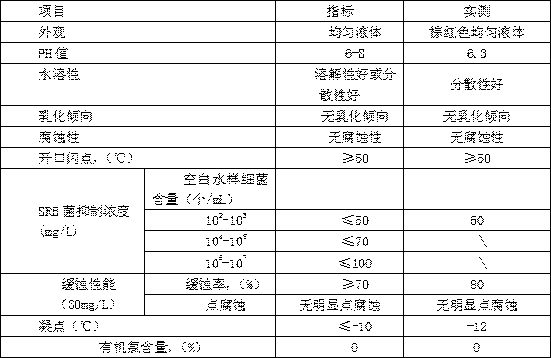

Embodiment 2

[0032] A kind of preparation method of oil field compound type bactericidal corrosion inhibitor, concrete steps are as follows:

[0033] Step 1: Put 30kg of oleic acid, 5kg of naphthenic acid and 18kg of diethylenetriamine into the reaction kettle, raise the temperature to 160 degrees Celsius, turn on the condenser to cool the water, and react for 2 hours, observe the water out, during which there should be water formed and condensed take over;

[0034] In step 2, the reaction kettle is heated to 190 degrees Celsius, reacted for 2 hours, and then heated to 230 degrees Celsius, and after 4 hours of reaction, there should be basically no more water at this time, and the temperature is lowered to 50 degrees Celsius;

[0035] Step 3, add methanol 30kg again in the reactor, and the reactor was reacted at 42 degrees centigrade for 0.5 hour;

[0036] Step 4, pump 17kg of glacial acetic acid into the dripping tank, slowly drop it, the reaction is an exothermic reaction, control the s...

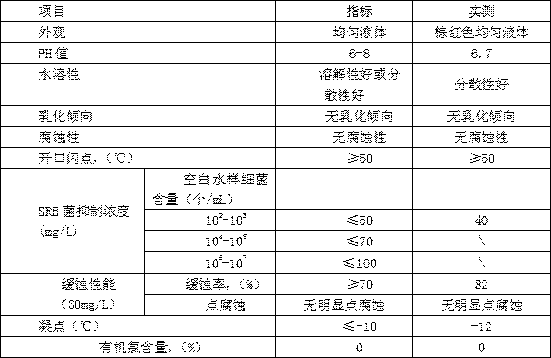

Embodiment 3

[0045] A kind of preparation method of oil field compound type bactericidal corrosion inhibitor, concrete steps are as follows:

[0046] Step 1, put 22kg of oleic acid, 15kg of naphthenic acid and 20kg of diethylenetriamine into the reaction kettle, raise the temperature to 160 degrees Celsius, turn on the condenser to cool the water, and react for 2 hours, observe the water out, during which there should be water formed and condensed take over;

[0047] In step 2, the temperature of the reactor is raised to 190 degrees Celsius, reacted for 2 hours, and then heated to 230 degrees Celsius, and after 4 hours of reaction, there should be basically no more water at this time, and the temperature is lowered to 50 degrees Celsius;

[0048] Step 3, add methanol 25kg again in the reactor, and the reactor was reacted at 42 degrees centigrade for 0.5 hour;

[0049] Step 4: Pump 18 kg of glacial acetic acid into the dripping tank and add slowly, the reaction is an exothermic reaction, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com