Pressure control system and method

A technology of pressure control and control method, which is applied in the direction of fluid pressure control, control/regulation system, electric fluid pressure control, etc. It can solve the problems that affect the production rate of the machine, prone to abnormalities, and gas fluctuations, etc., to achieve The effect of improving equipment utilization rate, increasing machine productivity, and reducing the probability of gas flow rate fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Research has found that the main reason for the above problems lies in the structure of the inflatable device used in the prior art for the loading chamber.

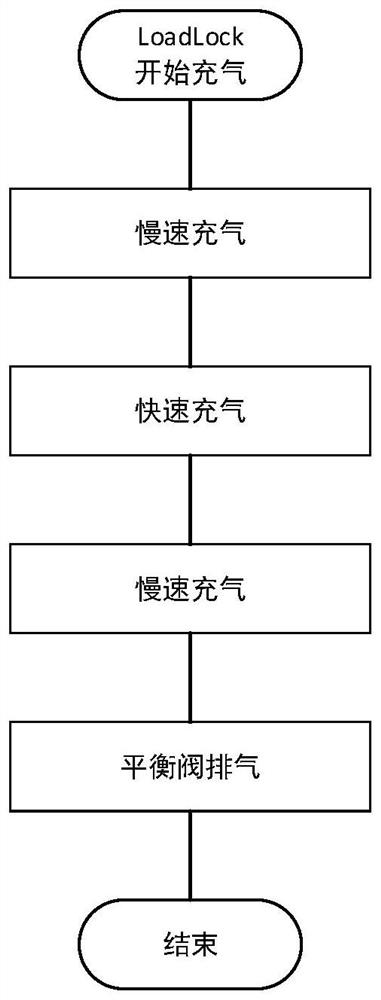

[0034] Concretely, when the loading chamber of the existing machine is inflated, the inflated gas is generally nitrogen (N 2 ), the inflation control process is as follows figure 1shown. When the loading chamber is inflated, first open the slow filling valve to inflate, when the loading chamber reaches a certain pressure, close the slow filling valve, then open the fast filling valve to inflate, when the loading chamber reaches close to atmospheric pressure, close the fast filling valve, Then open the slow filling valve and charge for a certain period of time, then close the slow filling valve, so that the detection pressure of the loading chamber reaches a level slightly higher than the standard atmospheric pressure, and finally open the balance valve to exhaust the chamber outward, so that the pressure of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com