A Side Pump Combiner for High Power Fiber Laser Systems

A fiber laser, high-power technology, applied in the direction of lasers, laser components, cladding optical fibers, etc., can solve the problems of light field distribution, light spot roundness easily disturbed, light spot deterioration, etc., to avoid heat accumulation damage to optical fiber, reduce stress Sensitivity, effect of optimizing beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

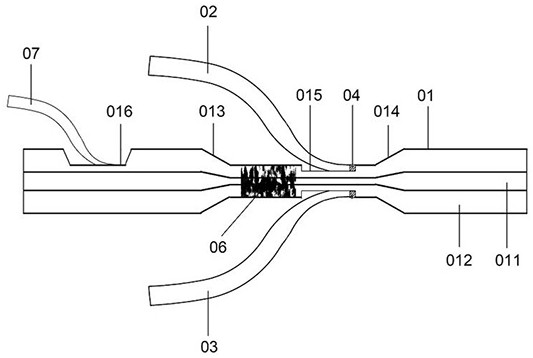

[0019] figure 1 The structure of the side-pump beam combiner used in the high-power fiber laser system provided by the embodiment of the present invention is shown, and only the parts related to the embodiment of the present invention are shown for convenience of description.

[0020] like figure 1 As shown, the side-pump beam combiner for high-power fiber laser systems provided in this embodiment includes a signal fiber 01, the signal fiber includes a core 011 and a cladding 012, and the middle part of the signal fiber is tapered to form A tapered area, the tapered area includes a flat area and a tapered area located at both ends of the flat area, in the figure, the two tapered areas are marked as 013 and 014, and the cladding part of the flat area is formed with a first A cladding corrosion zone 015, the side wall end surface of the first cladding corrosion zone 015 is bonded with a number of pumping fibers through the refractive index matching bonding solution 04, there ar...

Embodiment 2

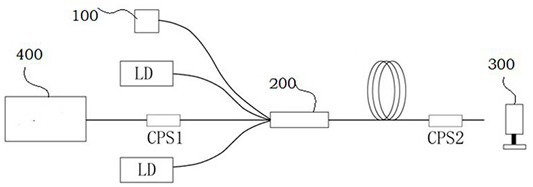

[0040] This embodiment provides an application scenario of the beam combiner, such as figure 2 As shown, the (2+1)×1 beam combiner 200 is used as a forward beam combiner for the fiber amplifier, the output fiber size of the seed source 400 is 20 / 400, and passes through a 20 / 400-30 / 400 mode field matcher (MFA ) into the beam combiner. The core-to-cladding ratio of the LD tail fiber of the amplified semiconductor laser is 200 / 220, which is consistent with the size of the pump fiber of the beam combiner. The pump light is coupled into the cladding of the active fiber through the beam combiner. A cladding light stripper is fused at the output end to filter the cladding laser to improve the beam quality. A power meter 300 is shown for measuring the output power of the entire device. The test system 100 has multiple uses: 1) a power meter is placed behind it to monitor the backward optical power; 2) a spectrometer can be used to observe nonlinear effects (mainly stimulated Brillo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com