Method for improving permeability of areca fiber by using supercritical carbon dioxide technology

A carbon dioxide, supercritical technology, applied in the field of food processing, can solve the problems of high time cost and production cost, no significant increase in permeability, slow penetration of the raw material liquid, etc., so as to reduce production cost, improve chewing safety, No solvent residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

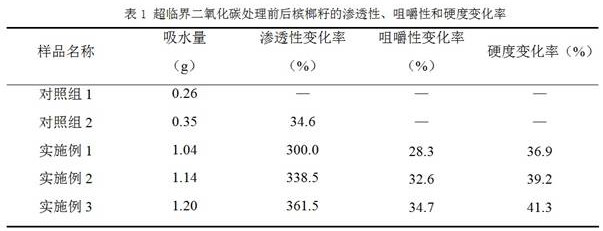

Embodiment 1

[0035] A method for improving the permeability of areca nut fibers by using supercritical carbon dioxide technology, comprising the following steps: transporting betel nut seeds into a supercritical carbon dioxide autoclave, sealing the autoclave, turning on a carbon dioxide feed pump, and filling the autoclave with gaseous Carbon dioxide raises the pressure inside the kettle to 20 MPa, and the mass ratio of betel nut seeds to supercritical carbon dioxide fluid is 1:0.8. Turn on the heating power to start heating, start timing when the temperature in the reactor reaches 35°C, and turn off the heating power after 30 minutes. Ventilate and cool down to below 30°C and open the vent valve of the reactor. The supercritical carbon dioxide is vaporized into gaseous carbon dioxide due to the rapid drop in pressure, and escapes from the fiber structure of the betel nut, which has a fiber softening effect on the betel nut seeds. The collected gas is compressed by the compressor and sent...

Embodiment 2

[0037] A method for improving the permeability of betel nut fibers by using supercritical carbon dioxide technology, comprising the following steps: a method for improving the permeability of areca nut fibers by using supercritical carbon dioxide technology, comprising the steps of: transporting betel nut seeds into a supercritical carbon dioxide high-pressure reactor , seal the reactor, turn on the carbon dioxide feed pump, fill the autoclave with gaseous carbon dioxide to raise the internal pressure to 15 MPa, and the mass ratio of betel nut seeds to supercritical carbon dioxide fluid is 1:0.6. Turn on the heating power supply to start heating, start timing when the temperature in the reactor reaches 50°C, and turn off the heating power supply after 40 minutes. Ventilate and cool down to below 30°C and open the vent valve of the reactor. The supercritical carbon dioxide is vaporized into gaseous carbon dioxide due to the rapid drop in pressure, and escapes from the fiber stru...

Embodiment 3

[0039] A method for improving the permeability of betel nut fibers by using supercritical carbon dioxide technology, comprising the following steps: a method for improving the permeability of areca nut fibers by using supercritical carbon dioxide technology, comprising the steps of: transporting betel nut seeds into a supercritical carbon dioxide high-pressure reactor , seal the reactor, turn on the carbon dioxide feed pump, fill the autoclave with gaseous carbon dioxide to raise the internal pressure to 25 MPa, and the mass ratio of betel nut seeds to supercritical carbon dioxide fluid is 1:1.1. Turn on the heating power supply to start heating, start timing when the temperature in the reactor reaches 45°C, and turn off the heating power supply after 35 minutes. Ventilate and cool down to below 30°C and open the vent valve of the reactor. The supercritical carbon dioxide is vaporized into gaseous carbon dioxide due to the rapid drop in pressure, and escapes from the fiber stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com