Method for preparing cream-flavor composite aromatic base through two-step enzymolysis combined fermentation

A fragrance-based and milk-flavored technology, which is applied to bacteria, dairy products, cream preparations, etc. used in food preparation, can solve the problem that the antagonism of bacteria and enzymes cannot maximize the benefits, and the single lack of protein source nutrition and flavor substances is not enough. Green, safe and natural, etc., to make up for high production costs, expand nutritional value, flavor and taste types, and speed up the rate of aroma production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

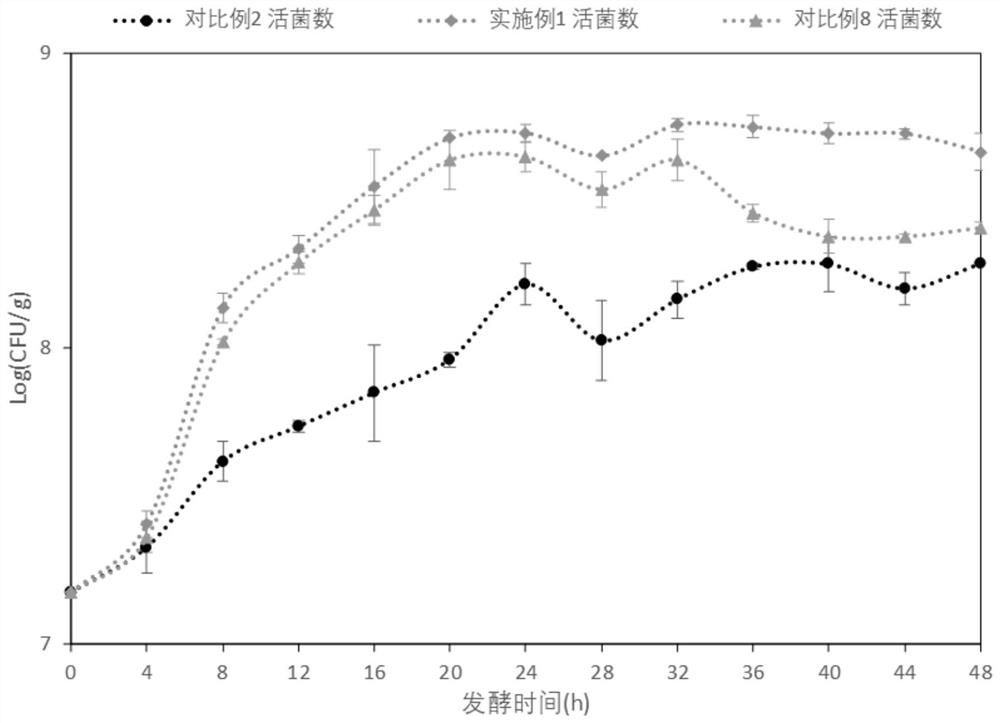

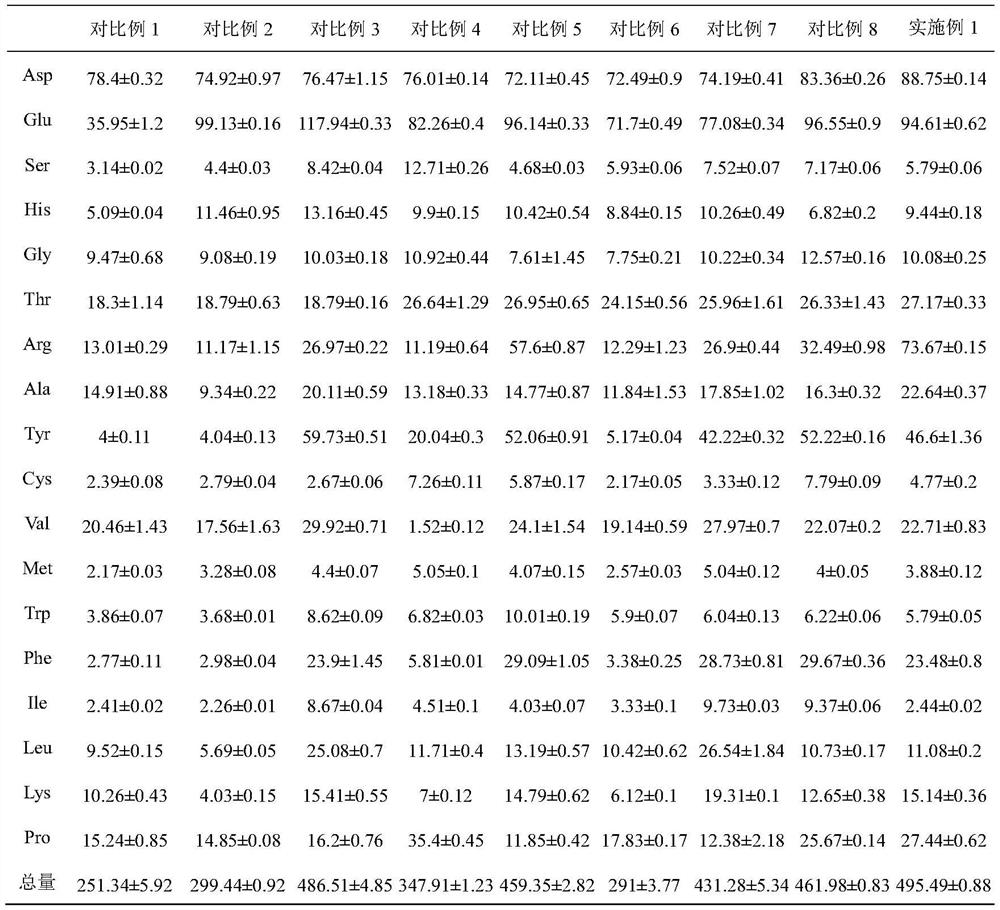

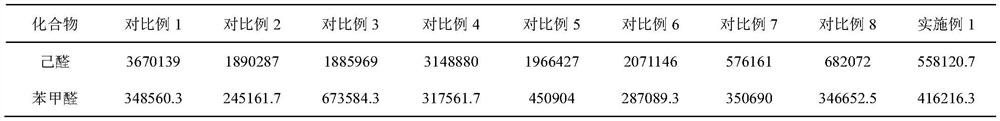

[0059] Embodiment 1: the preparation of milky compound fragrance base

[0060] A method for preparing a milk-flavored compound fragrance base by using soybean protein instead of butter two-step enzymatic hydrolysis combined with fermentation, the steps are as follows:

[0061] (1) After fully mixing 100g of cream and 5g of soybean protein, add 7.5g of water to obtain a liquid substrate with a mass concentration of 40%, and homogenize the prepared substrate. The homogeneous conditions are 75°C, 20Mpa, After homogenization, sterilize at 95°C for 15 minutes, and cool down the substrate to 25°C;

[0062] (2) Preparation of Lactobacillus suspension

[0063] Pick a single colony of Lactobacillus bulgaricus and inoculate it in 1 mL of mMRS liquid medium. After anaerobic cultivation at 30°C for 18 hours, the seed liquid is prepared, and the seed liquid is transferred to the mMRS liquid medium at an inoculation amount of 2% (v / v). , after culturing for 24 hours, the fermentation brot...

Embodiment 2

[0066] Embodiment 2: the preparation of milky compound fragrance base

[0067] A method for preparing a milk-flavored compound fragrance base by using soybean protein instead of butter two-step enzymatic hydrolysis combined with fermentation, the steps are as follows:

[0068] (1) After fully mixing 120g cream and 50g soybean protein, add 45.43g water to obtain a liquid substrate with a mass concentration of 70%, and homogenize the prepared substrate. The homogeneous conditions are 75°C, 20Mpa, After massaging, sterilize at 90°C for 17 minutes, and cool down the substrate to 30°C;

[0069] (2) Preparation of Lactobacillus suspension

[0070] Single colonies of Lactococcus lactis and Lactobacillus casei were picked out, respectively inoculated in 1mL mMRS liquid medium, and after anaerobic culture at 30°C for 18 hours, the seed liquid was prepared, and the seed liquid was mixed with 2% (v / v) The inoculation amount was transferred to mMRS liquid medium, and after culturing for...

Embodiment 3

[0073] Embodiment 3: the preparation of milky compound fragrance base

[0074] A method for preparing a milk-flavored compound fragrance base by using soybean protein instead of butter two-step enzymatic hydrolysis combined with fermentation, the steps are as follows:

[0075] (1) After fully mixing 150g butter and 150g soybean protein, add 804g water to prepare a liquid substrate with a mass concentration of 25%, and homogenize the prepared substrate. The homogenization conditions are 75°C, 20Mpa, homogeneous After the end, sterilize at 85°C for 20 minutes, and cool down the substrate to 30°C;

[0076] (2) Preparation of Lactobacillus suspension

[0077] Pick single colonies of Lactobacillus paracasei and Lactobacillus plantarum to inoculate, respectively inoculate in 1mL mMRS liquid medium, and prepare seed liquid after anaerobic culture at 30°C for 18 hours, and inoculate the seed liquid with 2% (v / v) The amount of inoculum was transferred to the mMRS liquid medium, and aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com