Method and device for removing organic sulfur in gas by using compound ionic liquid desulfurizer

An ionic liquid and desulfurization device technology, which is applied in the field of compound ionic liquid desulfurizers, can solve problems such as poor organic sulfur removal effect, and achieve excellent organic sulfur removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

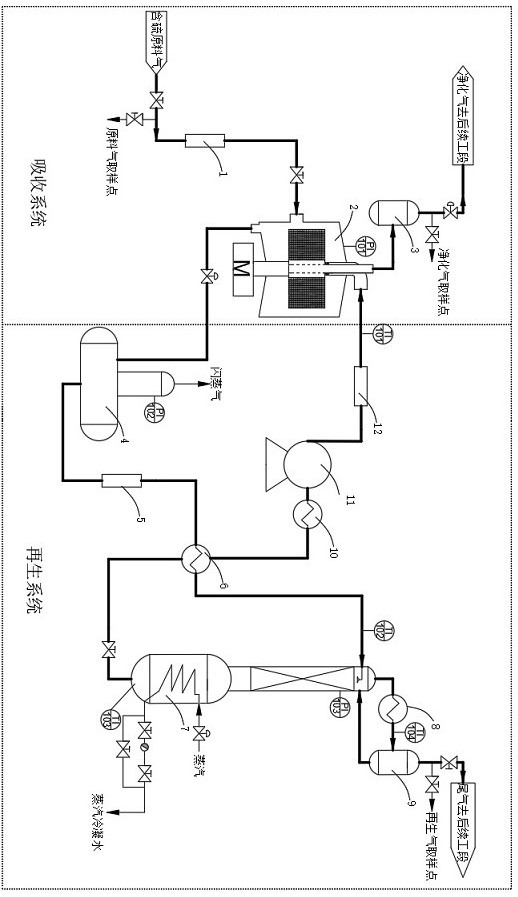

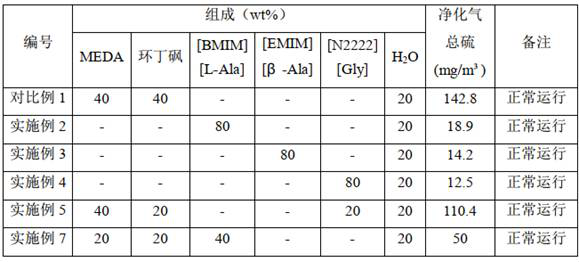

[0032] Configuration comparative example 1-3 and embodiment 1-3 desulfurizer, adopt such as figure 1 The shown desulfurization device performs organic sulfur treatment on a certain sulfur-containing natural gas at 30°C and 0.5 MP. The sour gas components of the sulfur-containing natural gas are mainly common organic Sulfur, with a total sulfur content of 357 mg / m³.

[0033] The result of the operation is as follows:

[0034]

[0035]Note: Among them, [N2222][Gly] is tetraethylamine glycinate, [BMIM][L-Ala] is 1-butyl-3-methylimidazolium L-alanine salt, [EMIM][β-Ala] For 1-ethyl-3-methylimidazole β-alanine salt.

[0036] It can be seen from the results in the above table that compared with the traditional sulfone amine solvent, the desulfurization effect of amino acid ionic liquid is significantly improved, and in the composite desulfurizer, with the increase of the proportion of amino acid ionic liquid, the desulfurization effect continues to improve.

[0037] In the tra...

Embodiment B

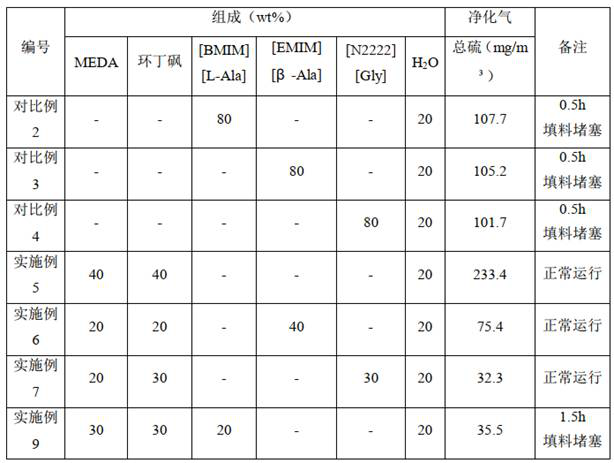

[0039] Configure comparative example 2 and embodiment 5-9 desulfurizer, adopt such as figure 1 The shown desulfurization device treats the associated gas of a sulfur-containing oilfield with organic sulfur at 30°C and 0.5MP. The sour gas component contains 9.2% CO 2 In addition, it is mainly common organic sulfur such as methyl mercaptan, ethanethiol, propylene mercaptan, and carbonyl sulfide, with a total sulfur content of 370 mg / m³.

[0040] The result of the operation is as follows:

[0041]

[0042] Although amino acid ionic liquids can desulfurize gases better than traditional sulfone amine solvents, when the gas contains CO 2 , due to CO 2 Reaction with desulfurization agent will interfere with desulfurization effect. right without CO 2 When the desulfurization of sulfur-containing raw gas is carried out, the desulfurization effect is continuously improved with the increase of the proportion of amino acid ionic liquids, but when carbon dioxide exists, the desulfur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com