Preparation method and application of lysine functionalized layered double hydroxide adsorbent

A hydroxide, lysine technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve problems such as poor adsorption performance and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

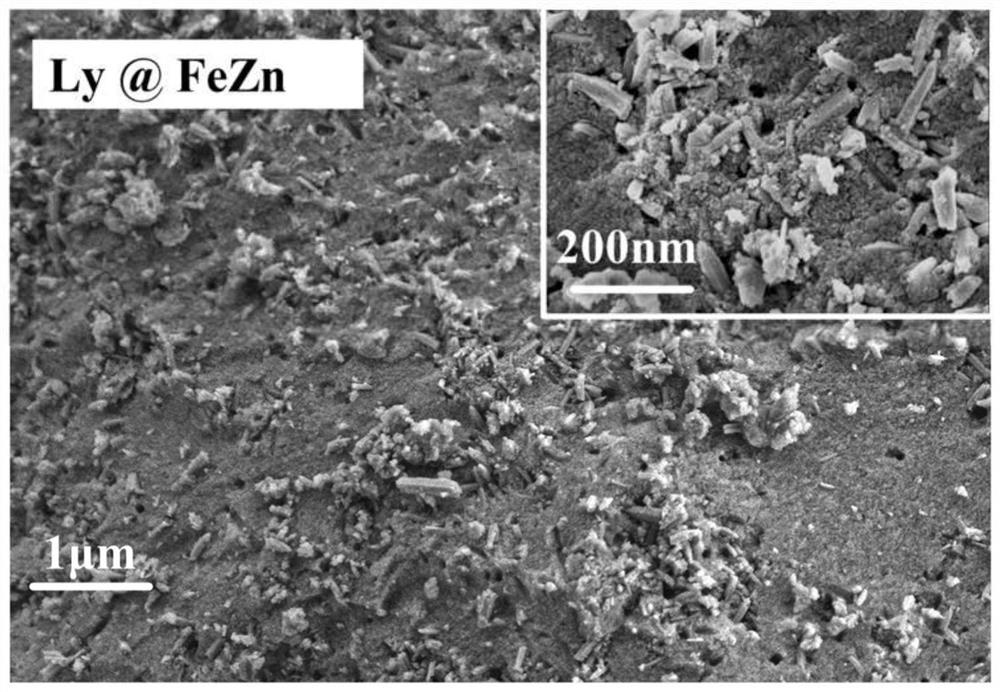

Image

Examples

Embodiment 1

[0029] A preparation method of Ly@FeZn adsorbent, comprising the steps of:

[0030] a) 3mmol Fe(NO 3 ) 3 9H 2 O and 6mmol Zn(NO 3 ) 2 ·6H 2 O was dissolved in 100mL deionized water;

[0031] b) adjusting the pH value of the above mixed solution to 10 with a concentration of 1M NaOH;

[0032] c) 5.8mmol lysine was slowly added to the mixture and stirred for 5 minutes;

[0033] d) sealing the obtained mixed solution in an autoclave lined with polytetrafluoroethylene, adjusting the oven temperature to 60° C., and hydrothermally reacting for 24 hours;

[0034] e) Take out the mixed solution after the reaction, pour out the supernatant, pour the remaining mixture into a centrifuge tube, adjust the speed of the centrifuge to 4000rpm, centrifuge for 3 minutes, and separate the solid;

[0035] f) The separated solid was washed three times with deionized water, and finally dried in an oven at 60 °C for 12 hours to obtain Ly@FeZn adsorbent.

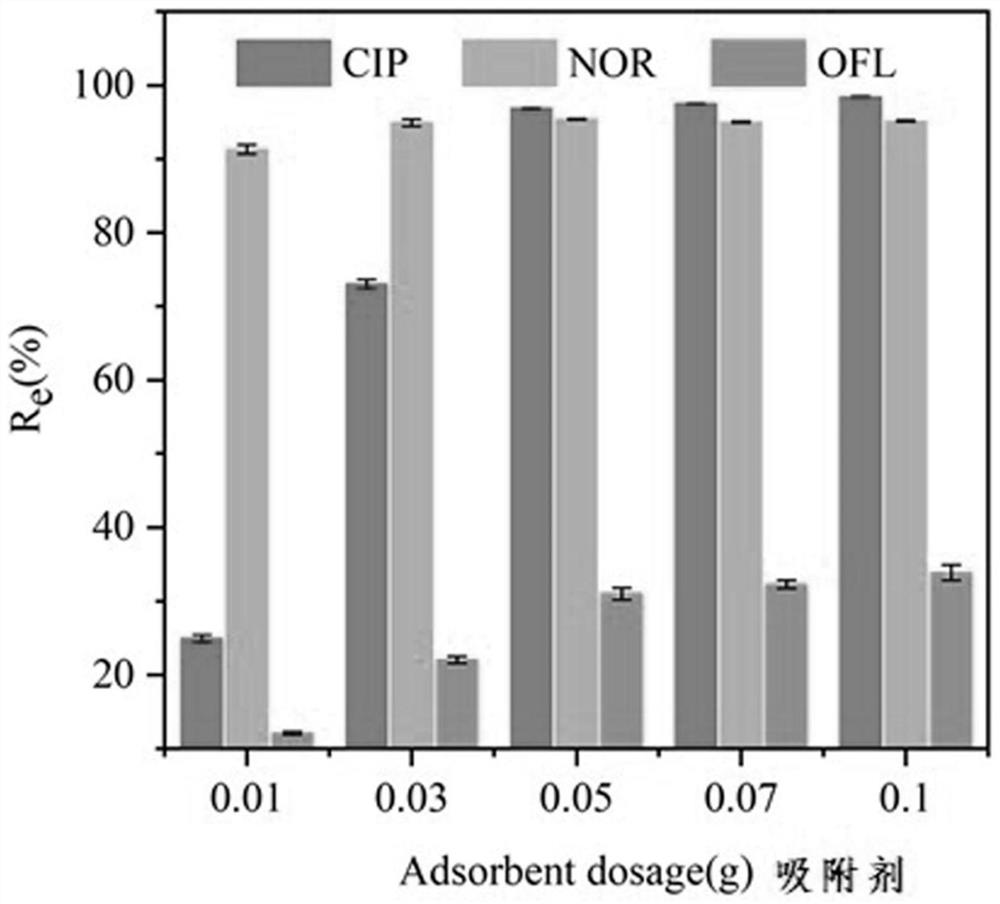

[0036] Experiments showed that the ...

Embodiment 2

[0038] A preparation method of Ly@FeZn adsorbent, comprising the steps of:

[0039] a) 3mmol Fe(NO 3 ) 3 9H 2 O and 6mmol Zn(NO 3 ) 2 ·6H 2 O was dissolved in 100mL deionized water;

[0040] b) adjusting the pH value of the above mixed solution to 10 with a concentration of 1M NaOH;

[0041] c) 5.8mmol lysine was slowly added to the mixture and stirred for 5 minutes;

[0042]d) sealing the obtained mixed solution in an autoclave lined with polytetrafluoroethylene, adjusting the oven temperature to 60° C., and hydrothermally reacting for 24 hours;

[0043] e) Take out the mixed solution after the reaction, pour out the supernatant, pour the remaining mixture into a centrifuge tube, adjust the speed of the centrifuge to 4000rpm, centrifuge for 3 minutes, and separate the solid;

[0044] f) The separated solid was washed three times with deionized water, and finally dried in an oven at 60 °C for 12 hours to obtain Ly@FeZn adsorbent.

[0045] Experiments showed that the r...

Embodiment 3

[0047] A preparation method of Ly@FeZn adsorbent, comprising the steps of:

[0048] a) 3mmol Fe(NO 3 ) 3 9H 2 O and 6mmol Zn(NO 3 ) 2 ·6H 2 O was dissolved in 100mL deionized water;

[0049] b) adjusting the pH value of the above mixed solution to 10 with a concentration of 1M NaOH;

[0050] c) 5.8mmol lysine was slowly added to the mixture and stirred for 5 minutes;

[0051] d) sealing the obtained mixed solution in an autoclave lined with polytetrafluoroethylene, adjusting the oven temperature to 60° C., and hydrothermally reacting for 24 hours;

[0052] e) Take out the mixed solution after the reaction, pour out the supernatant, pour the remaining mixture into a centrifuge tube, adjust the speed of the centrifuge to 4000rpm, centrifuge for 3 minutes, and separate the solid;

[0053] f) The separated solid was washed three times with deionized water, and finally dried in an oven at 60 °C for 12 hours to obtain Ly@FeZn adsorbent.

[0054] Experiments showed that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com