Porous Ag@Cu2O nano cell material, preparation method and application thereof

A nano-cell technology, applied in the fields of materials science and electrochemistry, to suppress the hydrogen evolution reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

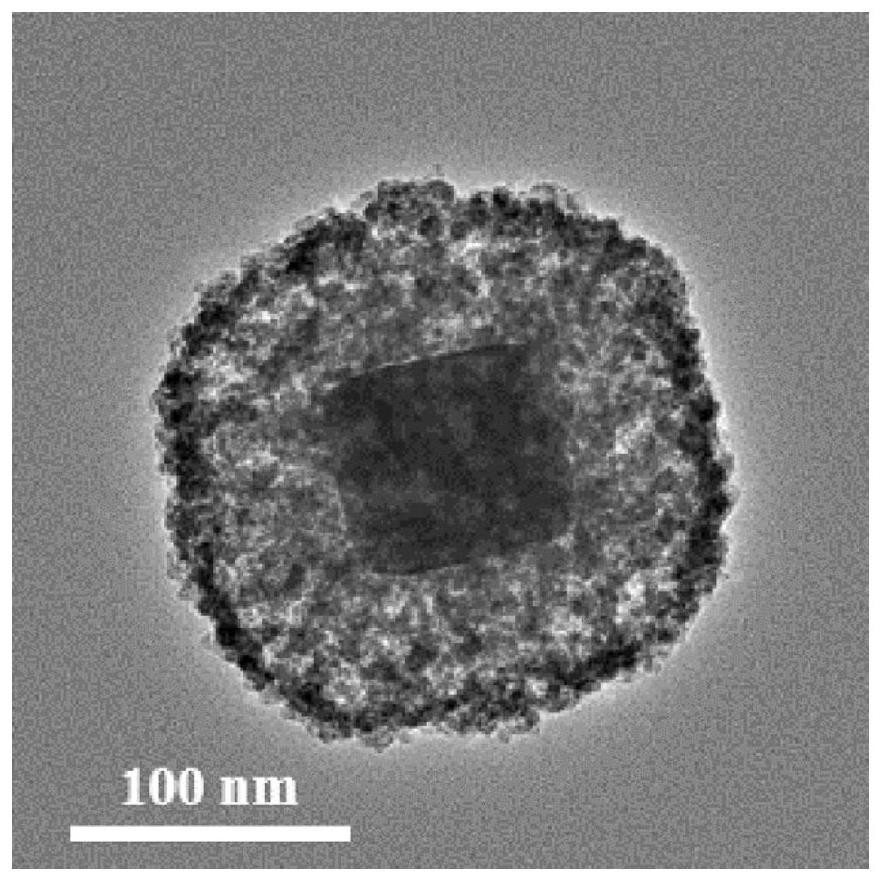

[0038] The present invention also provides the porous Ag@Cu 2 The preparation method of O nanometer cell material, comprises the following steps:

[0039] (1) Synthetic silver nanocube;

[0040] (2) Preparation of growth solution: disperse the silver nanocubes prepared in step (1) in polyvinylpyrrolidone aqueous solution, stir and mix evenly at high speed, then add copper nitrate trihydrate and ammonium sulfate, and stir to reach equilibrium;

[0041] (3) Porous Ag@Cu 2 The formation of 0 nano-compartment: sodium hydroxide aqueous solution is added dropwise to the growth solution prepared in the step (2), after the dropwise addition, continue to stir, then ascorbic acid is added dropwise in the above-mentioned solution, stop after a certain hour of rapid stirring, Obtain the porous Ag@Cu 2 O nanocompartment material.

[0042] In one embodiment of the present invention, the size of the silver nanocubic particles described in step (1) is 60-80 nm, preferably 68-72 nm, more p...

Embodiment 1

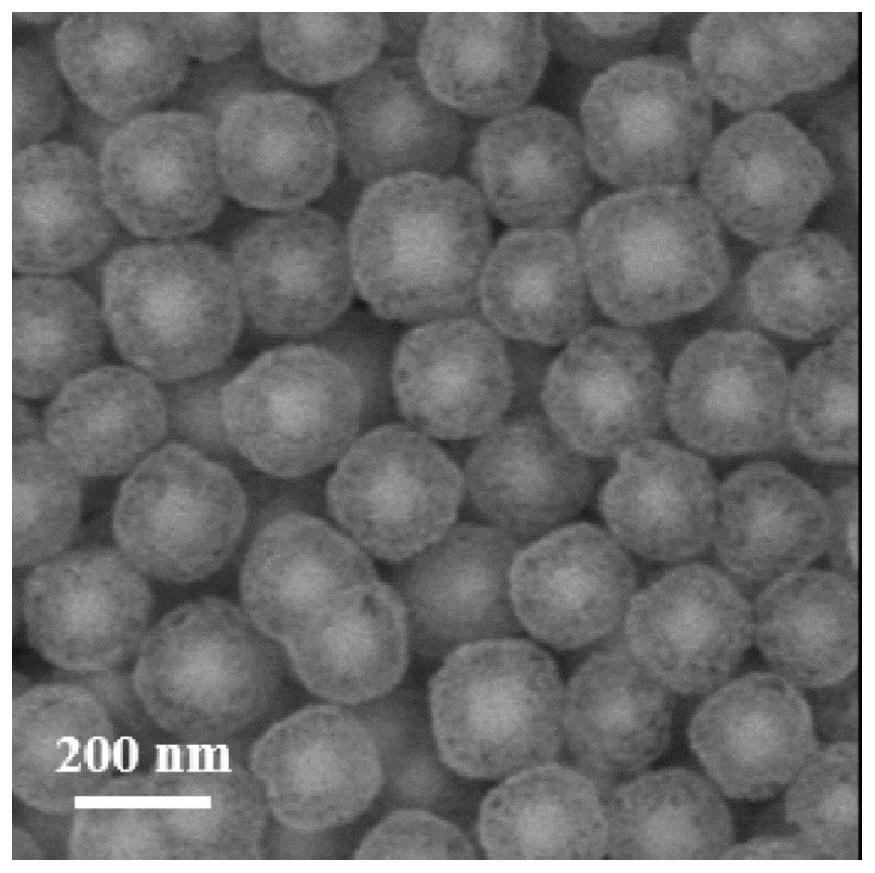

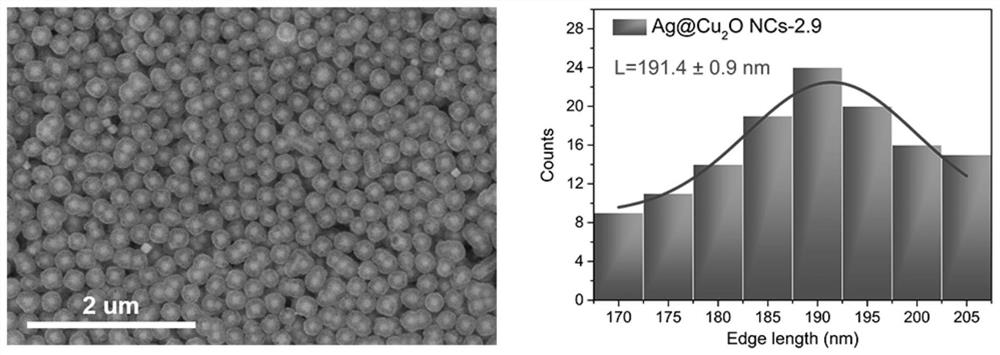

[0057] Preparation of a Porous Ag@Cu for Electrocatalytic Carbon Dioxide Reduction 2 O nano-compartment catalyst material:

[0058] (1) Add 5ml of ethylene glycol (EG) to a 25ml reaction flask in advance, and heat it at 105°C for 10 minutes, then add 250μl of EG solution of 60mM hydrochloric acid;

[0059] (2) After the above solution was stirred for 5 minutes, within 10 seconds, 5ml of 200mM AgNO 3 The EG solution was added thereto. After stirring for another 5 minutes, inject 5 ml of 120 mM polyvinylpyrrolidone (PVP) EG solution within 10 s;

[0060] (3) After the reaction was exposed to the air for 6 hours, the vial was capped and sealed, and the temperature was raised to 140° C. for another 10 minutes. The whole process of mechanical stirring is always kept at 1000rpm to achieve effective gas exchange;

[0061] (4) After the reaction was completed, the reaction was immediately quenched in an ice bath for 20 minutes, and the collected product was washed successively wit...

Embodiment 2

[0070] Preparation of a Porous Ag@Cu for Electrocatalytic Carbon Dioxide Reduction 2 O nano-compartment catalyst material:

[0071] (1) Add 5ml of ethylene glycol (EG) to a 25ml reaction flask in advance, and heat it at 105°C for 10 minutes, then add 250μl of EG solution of 60mM hydrochloric acid;

[0072] (2) After the above solution was stirred for 5 minutes, within 10 seconds, 5ml of 200mM AgNO 3 The EG solution was added thereto. After stirring for another 5 minutes, inject 5 ml of 120 mM polyvinylpyrrolidone (PVP) EG solution within 10 s;

[0073] (3) After the reaction was exposed to the air for 6 hours, the vial was capped and sealed, and the temperature was raised to 140° C. for another 10 minutes. The whole process of mechanical stirring is always kept at 1000rpm to achieve effective gas exchange;

[0074] (4) After the reaction was completed, the reaction was immediately quenched in an ice bath for 20 minutes, and the collected product was washed successively with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com