Gas-solid phase photo-Fenton catalyst, and preparation method and application thereof

A catalyst, gas-solid phase technology, applied in the field of gas-solid phase photo-Fenton catalyst and its preparation, which can solve the problems of strict reaction conditions, rapid recombination, and high cost of waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] According to an embodiment provided by the present invention, it is a method for preparing a gas-solid phase photo-Fenton catalyst, characterized in that it comprises the following steps:

[0037] S1. Take a microwave reaction tube, add a metal source and ultrasonically disperse it in N'N-dimethylformamide (DMF), add the ligand under constant stirring, and add concentrated hydrochloric acid as a morphology regulator after it is completely dissolved, and stir After mixing, put it into the microwave reaction chamber;

[0038]S2. Control the microwave power in the microwave reaction chamber to 800-1400w, the initial pressure is 0-35bar, and the reaction temperature is 80-200°C. After the reaction is completed, after cooling to room temperature, the material is centrifugally washed and vacuum-dried to obtain a powdered MOF material;

[0039] S3. Then add MOF material to the reaction tube such as polytetrafluoroethylene tube, disperse in the organic solution, stir for 5 minu...

Embodiment 1

[0053] S1. Take a clean quartz microwave reaction tube and place it on the microwave reaction rack, first add 40mL N’N-dimethylformamide (DMF), then add 932mg (4mmol) metal source zirconium tetrachloride (ZrCl 4 , 233 g / mol), after ultrasonic dispersion, 724 mg (4 mmol) of ligand 2-aminoterephthalic acid (NH 2 -H 2 BDC, 181g / mol), after being completely dissolved, add 0.67mL concentrated hydrochloric acid, after stirring evenly, the microwave reaction rack is transferred into the microwave reaction chamber containing 150mL deionized water and seals the reaction chamber;

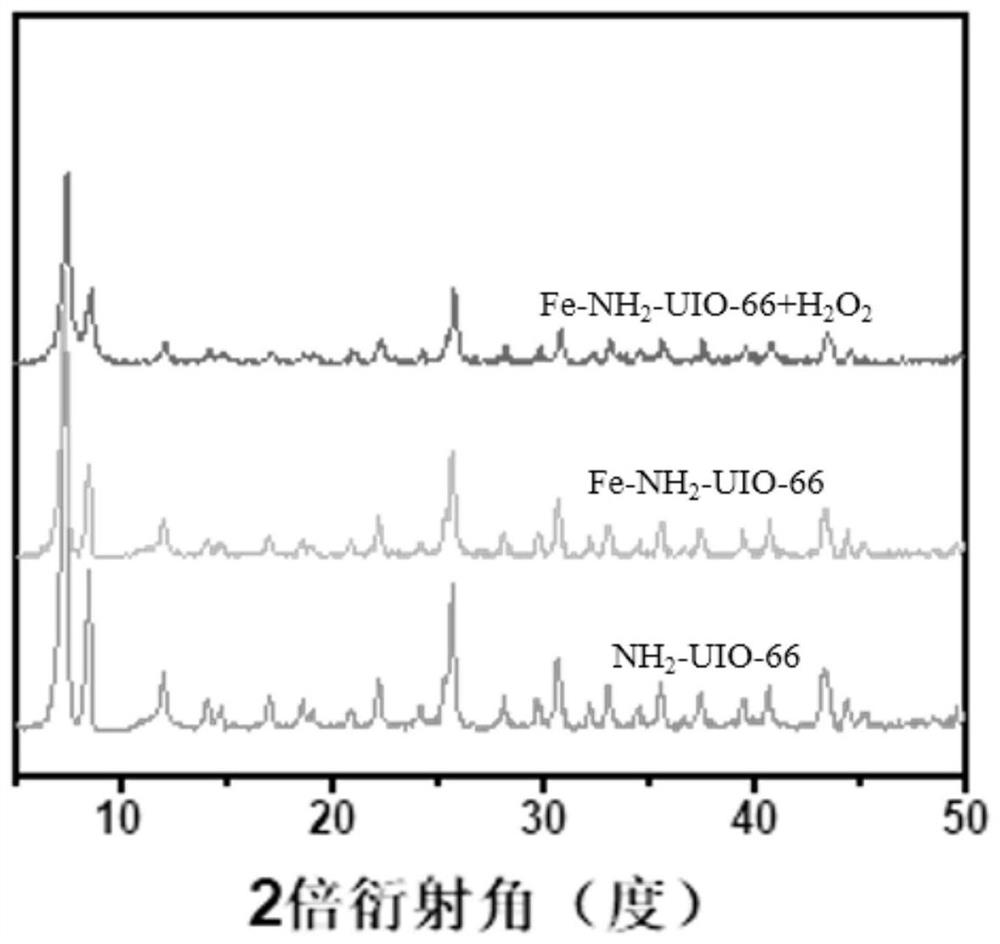

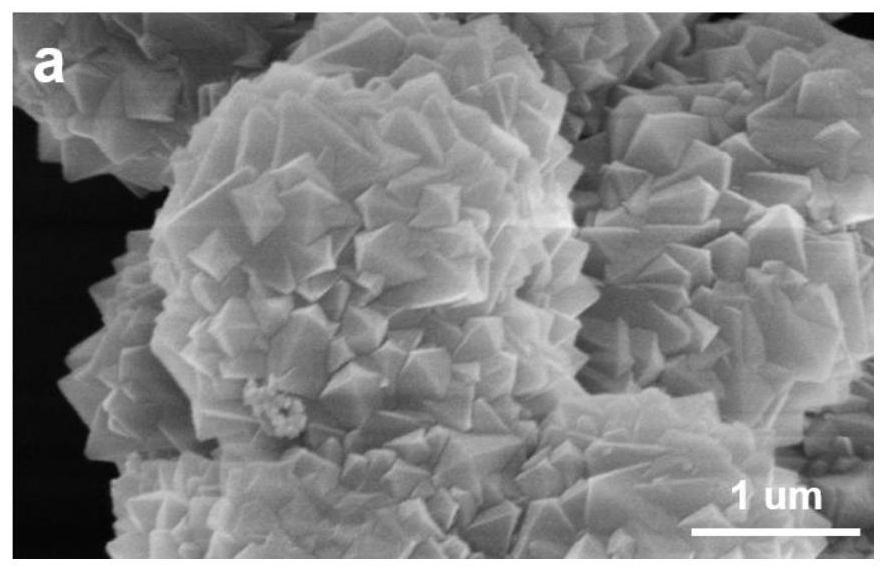

[0054] S2. In the microwave reaction chamber, the heating time is controlled to be 10min, the microwave power is 1200w, the initial pressure is 35bar, the reaction temperature is 120°C, and the reaction time is 45min. After cooling to room temperature, the material is washed 4 times by centrifugation with DMF and methanol respectively. And vacuum dried to obtain 1.2g light yellow powder sample NH 2 -UIO-66 ...

Embodiment 2

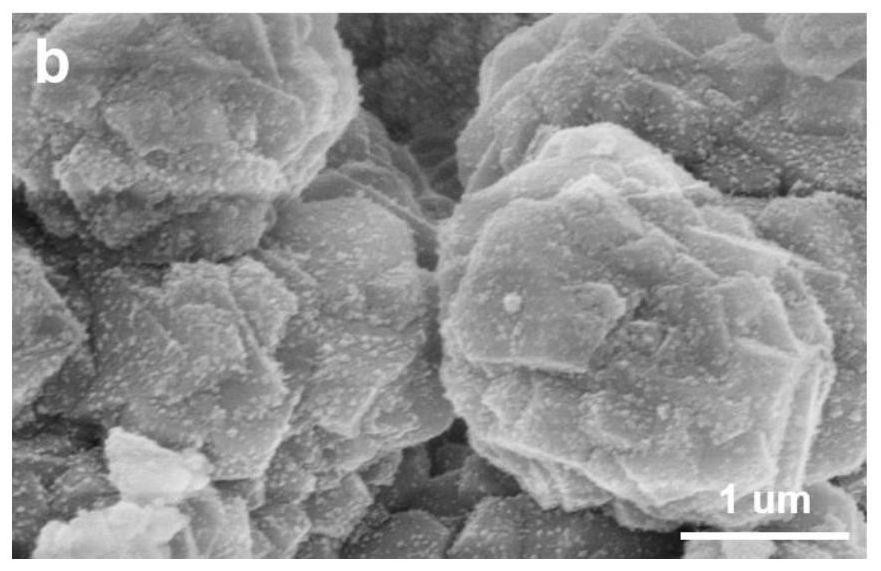

[0064] The steps of this embodiment and embodiment 1 are basically the same, the only difference is:

[0065] In step S1, add 932mg (4mmol) metal source zirconium tetrachloride (ZrCl 4 , 233g / mol), after ultrasonic dispersion, add 362mg (2mmol) ligand 2-aminoterephthalic acid (NH 2 -H 2 BDC, 181 g / mol).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com