A method for improving the catalytic activity of an electrode for CO2 electrochemical reduction

A catalytic activity, electrochemical technology, applied in the direction of electrodes, electrolytic components, electrolytic process, etc., can solve the problems of mass transfer polarization, etc., to achieve the effect of sufficient supply, improved selectivity, and increased production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

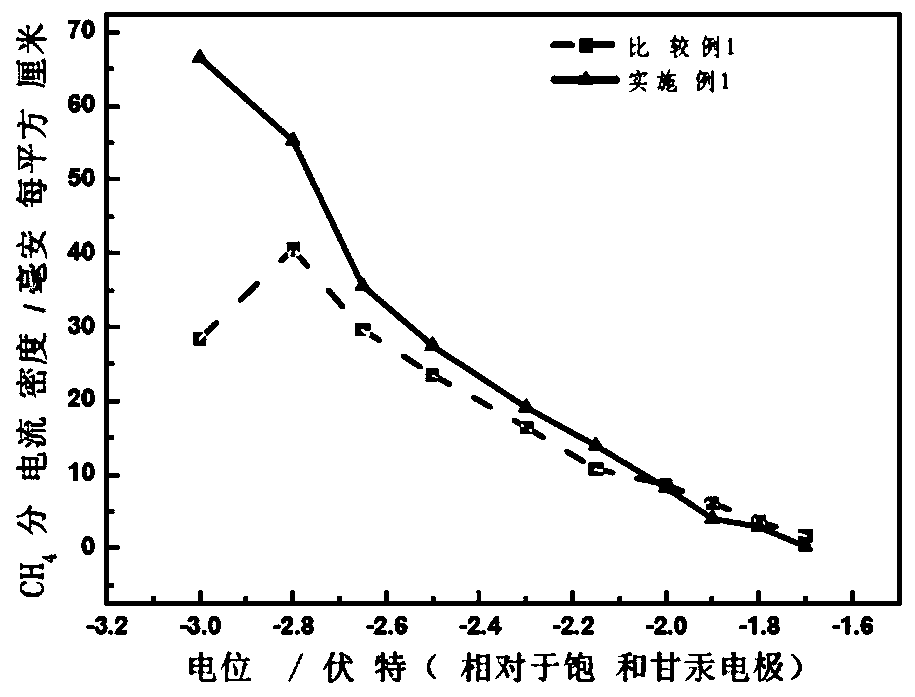

Embodiment 1

[0023] 1. Electrode material pretreatment: copper content ≥ 99.5%, thickness 100 microns, area 10 cm 2 The copper sheet is used as the electrode material. First, soak it in concentrated hydrochloric acid with a volume fraction of 36% to 38% at room temperature for 20 minutes to remove surface impurities, then rinse it with a large amount of deionized water until it is neutral, and use high-purity nitrogen blow dry;

[0024] 2. Preparation of the surface modifier solution: using analytically pure ethanol as the solvent and polycarbonate (PC) as the solute, a solution with a PC mass concentration of 5 mM was prepared.

[0025] 3. Surface modification of Cu sheet electrode: At room temperature, use a pipette to absorb 1ml of the surface modifier solution prepared in step 2, drop-coat it on the surface of the Cu sheet electrode that will be treated in step 1, and let it stand for 20s, and the Cu sheet electrode will appear Surface dry, control high purity N 2 The flow rate does ...

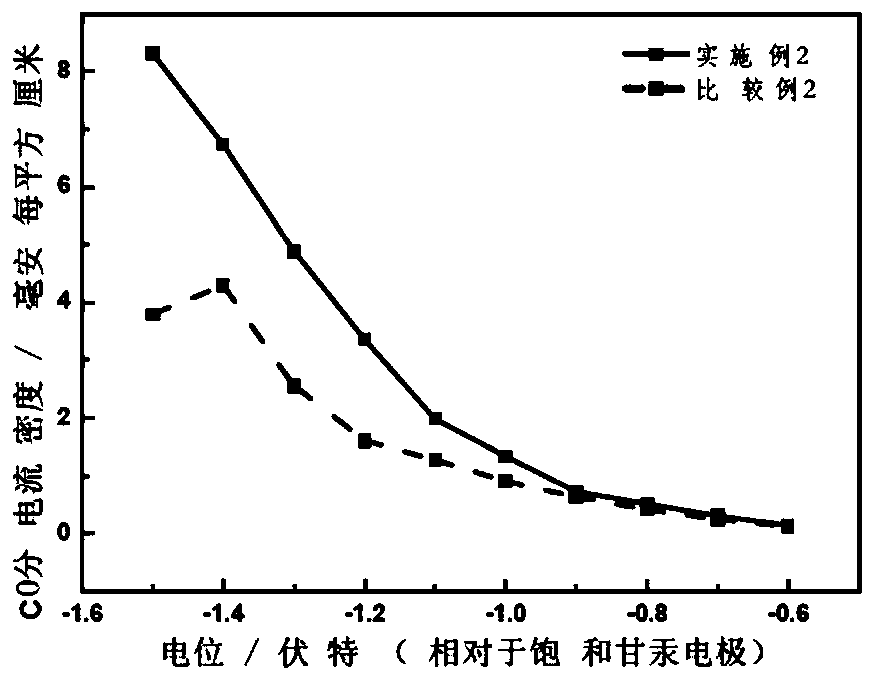

Embodiment 2

[0029] 1. Electrode material pretreatment: Silver content ≥ 99.5%, thickness 50 microns, area 10 cm 2 The silver sheet was used as the electrode material. First, it was soaked in phosphoric acid with a mass fraction of 85% at room temperature as the working electrode, the Pt sheet was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode. Use a potentiostat, control the electrolysis voltage to 1V and treat for 10 minutes to remove impurities such as surface scale, then rinse with a large amount of deionized water until neutral, and dry with high-purity argon;

[0030] 2. Preparation of the surface modifier solution: use analytically pure isopropanol as the solvent and dimethyl carbonate as the solute to prepare a surface modifier solution with a mass concentration of 20 mM.

[0031] 3. Surface modification of the Ag sheet electrode: At room temperature, use a straw to absorb 1ml of the surface modifier solution prepared in step ...

Embodiment 3

[0035] 1. Preparation of Au electrode supported by porous carbon paper: with a thickness of 0.10mm and an area of 5cm 2 The TGP-H-090 carbon paper is used as a porous conductive material, and it contains 5mM HAuCl 4 , 0.5M H 2 SO 4 In the plating solution, at 5mAcm -2 , Deposit a thin layer of Au particles on the surface of carbon paper under the condition of 30min, the loading of Au is about 0.3mg cm -2 . After taking out the electrode, rinse the surface with a large amount of deionized water, and dry it with high-purity Ar for later use;

[0036] 2. Electrode material pretreatment: use the loaded Au obtained in step 1 as the electrode material, first soak it in phosphoric acid with a mass fraction of 85% at room temperature as the working electrode, and use the Pt sheet as the counter electrode, and saturate calomel electrode as a reference electrode. Use a potentiostat, control the electrolysis voltage to 4V and treat for 5 minutes to remove impurities such as surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com