Perovskite CsPbI3-based quantum dot and preparation method thereof

A quantum dot and perovskite technology, applied in the field of luminescent materials, can solve the problems of decreased luminous efficiency, difficult to completely coat the surface of perovskite quantum dots, difficult to carboxylic acid, etc., so as to improve quantum yield and reduce luminescence. Defects, the effect of improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

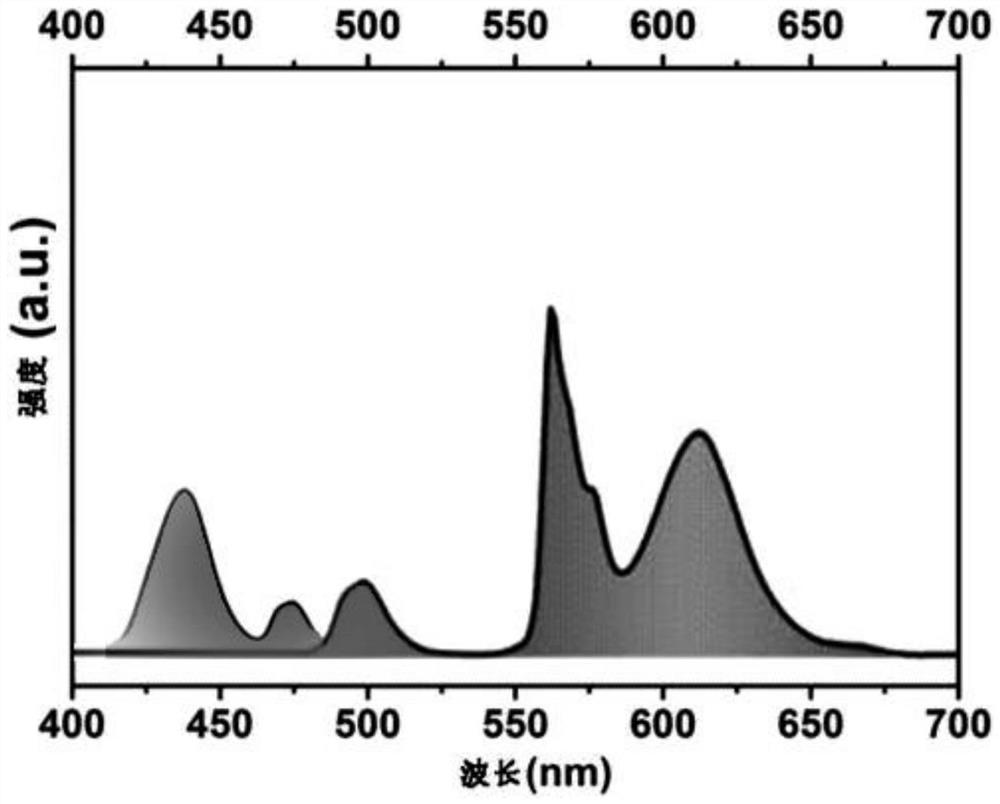

[0027] see figure 1 and image 3 As shown, this embodiment relates to a perovskite-based CsPbI 3 Quantum dot and preparation method thereof, its preparation comprises the following steps:

[0028] Step 1, according to the molecular formula perovskite CsPbI 3 The molar ratio of each element in the quantum dots is 1:1. Dissolve PbX2 powder and CsX powder in 15mL dimethyl sulfoxide to obtain mixed solution I. To mixed solution I, add 1.5mL oleic acid and 2mL oleylamine, and ultrasonically After about 10 minutes, the precursor solution was obtained after the mixed solution I was clarified, and then the precursor solution was added to toluene at a ratio of 1:45 to obtain a toluene solution of all-inorganic perovskite quantum dots.

[0029] Step 2, mix the toluene solution of the all-inorganic perovskite quantum dots or the toluene solution of the all-inorganic perovskite quantum dots CsPb(BrnA1-n)3 with the amphiphilic phospholipid chloroform solution and the oil-soluble nanopar...

Embodiment 2

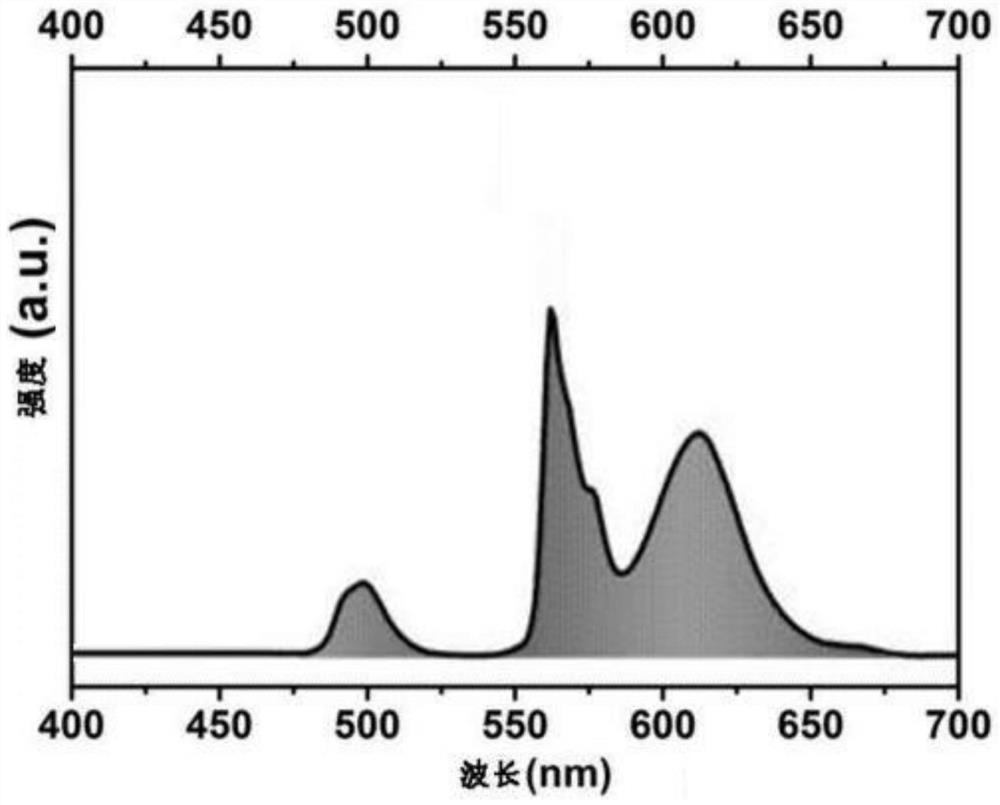

[0032] see figure 2 As shown, this embodiment relates to a perovskite-based CsPbI 3 Quantum dot and preparation method thereof, its preparation comprises the following steps:

[0033]Step 1: Dissolve lead bromide powder and cesium bromide powder in 10 mL of dimethyl sulfoxide at a molar ratio of 1:1, where the concentration of lead bromide is 0.4 mM; then add 1 mL of oleic acid and 0.5 mL of oleylamine to stabilize , sonicate until the solution is clear to obtain a precursor solution; slowly add 0.1 mL of the above precursor to 10 mL of toluene under vigorous stirring at 30 ° C to obtain an all-inorganic CsPbI 3 Perovskite quantum dots;

[0034] Step 2: Take 200 mg of dipalmitoylphosphatidylcholine powder and dissolve it in 20 mL of chloroform to obtain a 10 mg / mL dipalmitoylphosphatidylcholine chloroform solution.

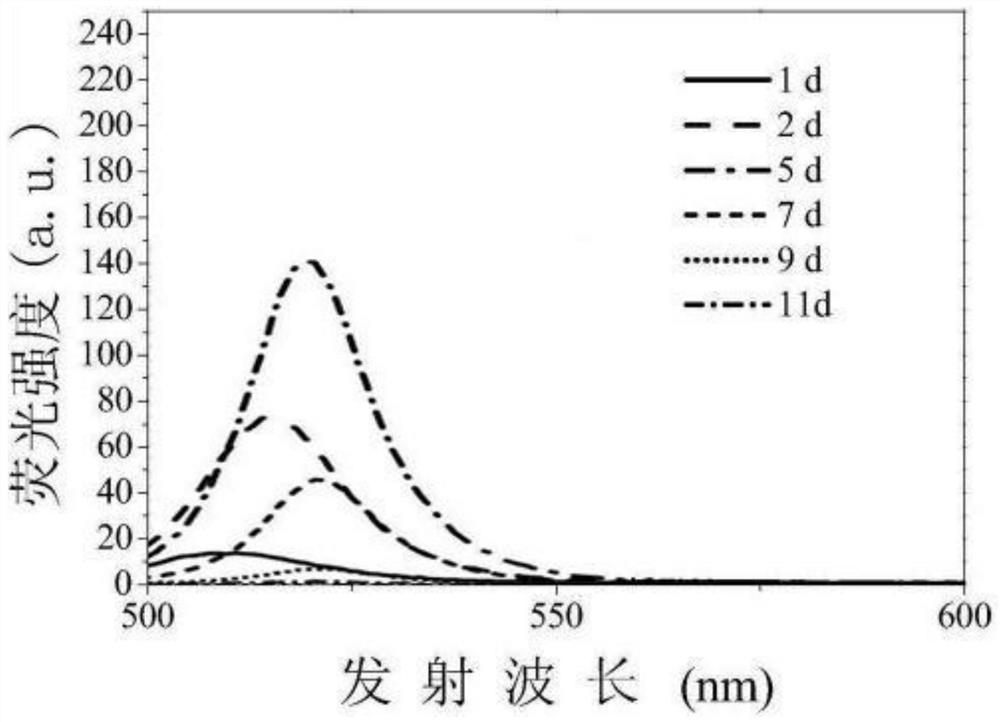

[0035] Step 3, in a 100mL single-necked flask, the all-inorganic CsPbI 3 The toluene solution of perovskite quantum dots and dipalmitoylphosphatidylcholine c...

Embodiment 3

[0039] A perovskite-based CsPbI 3 Quantum dot and preparation method thereof, its preparation comprises the following steps:

[0040] Step 1, take lead bromide powder and cesium bromide powder at a molar ratio of 1:1.5 and dissolve them in 20 mL of dimethyl sulfoxide, wherein the concentration of lead bromide is 0.8 mM; then add 2 mL of oleic acid and 1 mL of oleylamine to stabilize, Sonicate until the solution is clear to obtain a precursor solution; slowly add 0.1mL of the above precursor to 20mL of toluene under vigorous stirring at 30°C to obtain an all-inorganic CsPbI 3 Perovskite quantum dots;

[0041] Step 2: Take 150 mg of dipalmitoylphosphatidylcholine powder and dissolve it in 20 mL of chloroform to obtain a 10 mg / mL dipalmitoylphosphatidylcholine chloroform solution.

[0042] Step 3, in a 100mL single-necked flask, the all-inorganic CsPbI 3 The toluene solution of perovskite quantum dots and the dipalmitoylphosphatidylcholine chloroform solution were fully mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com