Light steel heat preservation integrated board and application and construction method thereof

An integrated panel and light steel technology, applied in thermal insulation, building structure, building thermal insulation materials, etc., can solve the problems of complex high-energy-saving wall structure, rising construction costs, and inconvenient installation and construction, so as to ensure energy-saving and emission-reduction effects, Improve construction efficiency and stabilize installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1 A kind of light steel thermal insulation integrated board

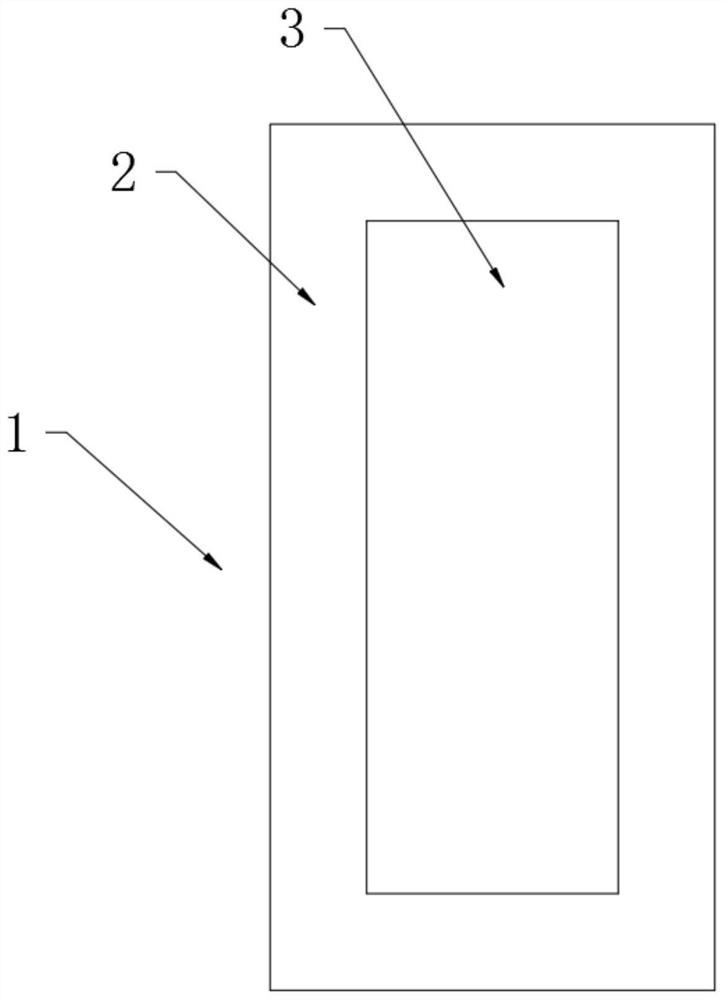

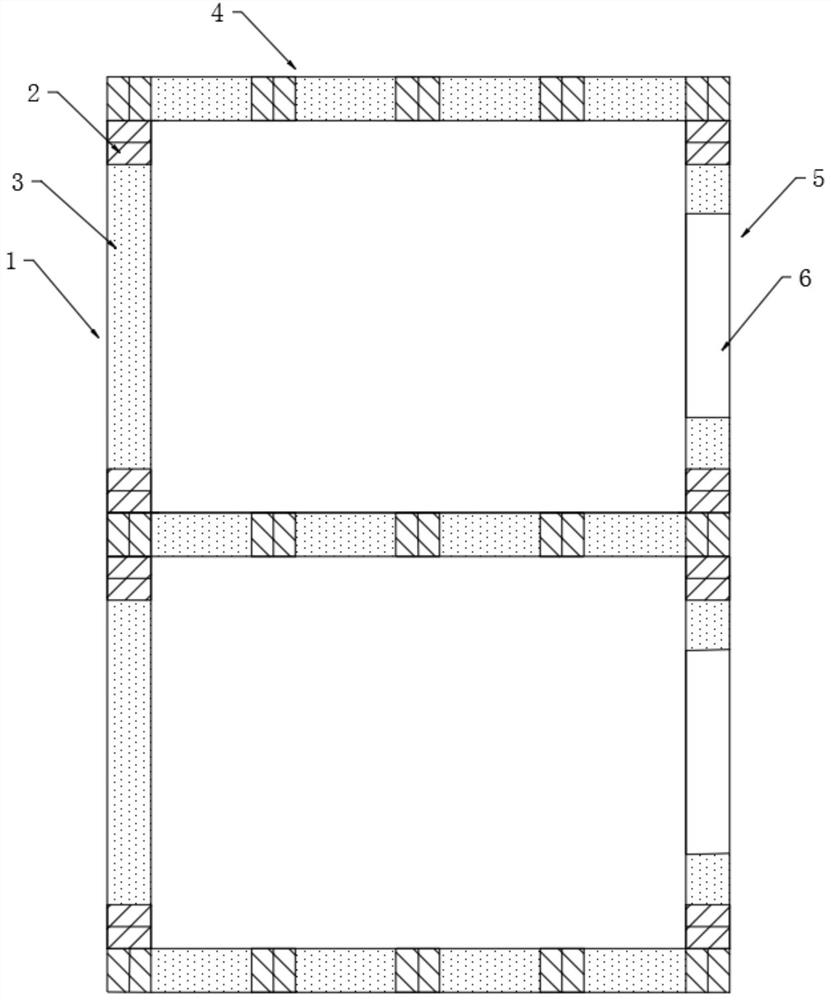

[0054] A light steel insulation integrated board, such as figure 1 As shown, the light steel insulation integrated board 1 includes a thin-walled light steel frame 2 and a graphite polystyrene board 3 . Among them, the graphite polystyrene board 3 is embedded in the thin-walled light steel frame 2, and the graphite polystyrene board 3 and the thin-walled light steel frame 2 are integrally formed by hot pressing, and the graphite polystyrene board 3 and the thin-walled light steel frame 2 have the same thickness. Specifically, the thin-walled light steel frame 2 is composed of C-shaped steel pressed from thin-walled light steel.

Embodiment 2

[0055] Embodiment 2 A kind of light steel thermal insulation integrated board

[0056] A light steel insulation integrated board, such as figure 1 As shown, the difference from Example 1 is that the graphite polystyrene plate 3 includes 100 parts by weight of polystyrene and 1.75-5 parts by weight of natural graphite. The rest of the settings are the same as in Example 1.

Embodiment 3

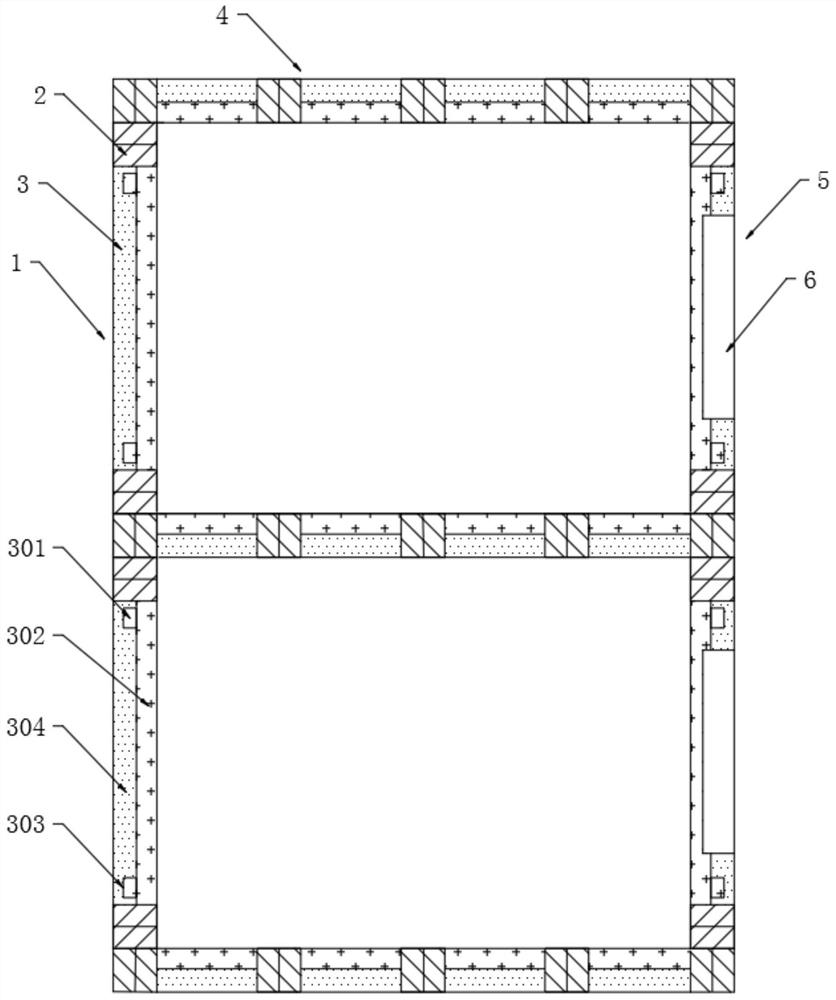

[0057] Example 3 A light steel insulation integrated board

[0058] A light steel insulation integrated board, the difference from Example 1 is that the graphite polystyrene board 3 includes a first graphite polystyrene layer 302 with a raised portion 301 and a second graphite polystyrene layer with a groove portion 303 304. This setting facilitates the mosaic assembly of the graphite polystyrene board 3 in the thin-walled light steel frame 2, and is convenient for thermoforming. The rest of the settings are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com