Rotary rock-fill triaxial dry-wet cycle test device and test method

A dry-wet cycle, rockfill technology, applied in measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve problems such as unreal test results and large differences in rockfill particle characteristics. The effect of sufficient drying and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

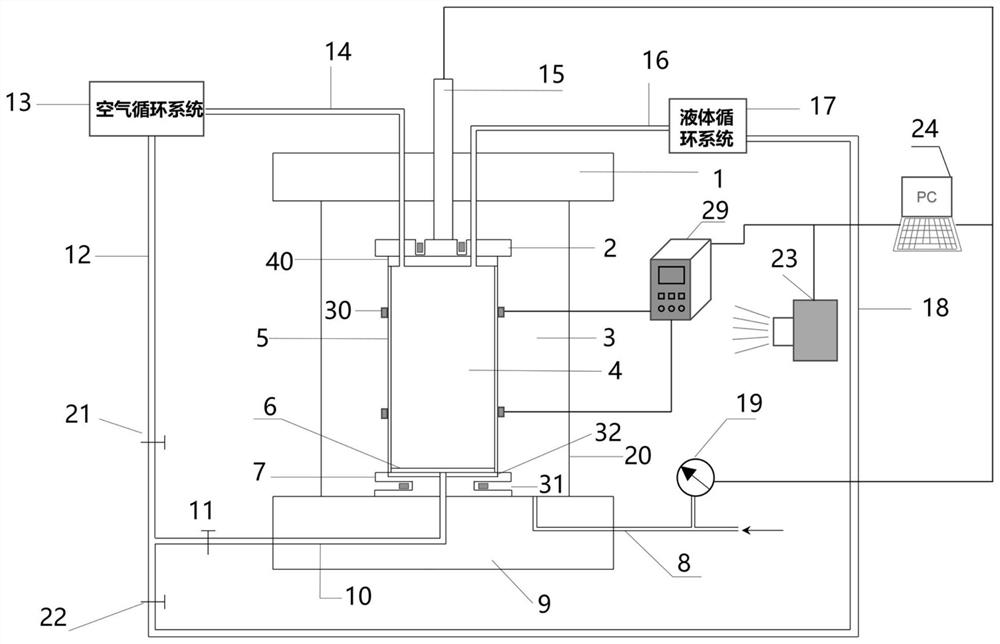

[0059] figure 1 The structure of the apparatus of the present invention is shown. A rotary stones three-axis dry wet circulation test device, including a rotary three-axis, an air circulation system 13, a liquid circulation system 17, a sound emission system, a CT device 23, and a computer control system 24.

[0060] The rotary three-axis includes a pressure chamber 3 and a rotatable three-axis container 4 disposed in the pressure chamber 3.

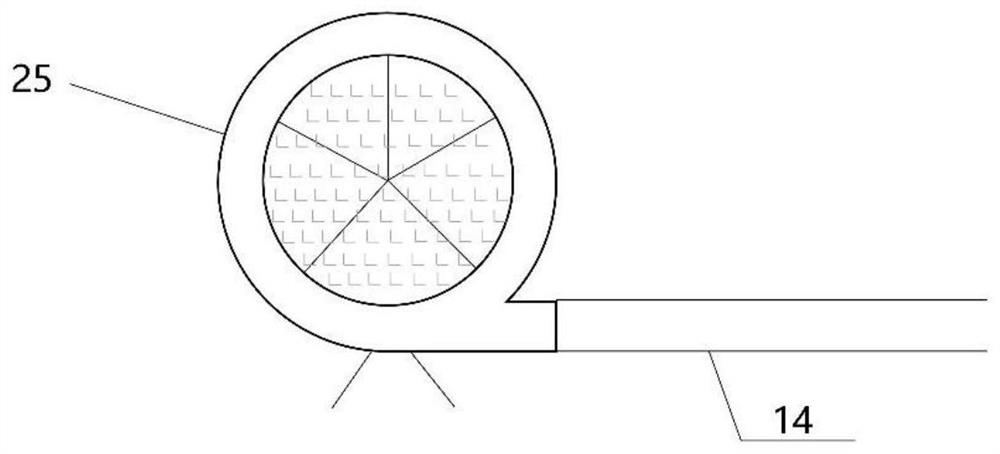

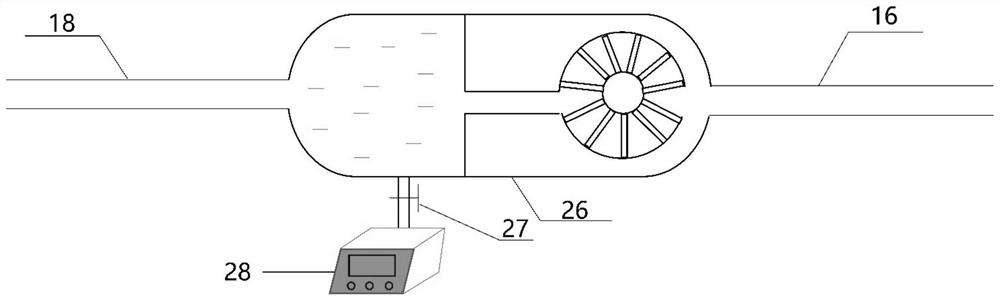

[0061] The three-axis container 4 is provided with a drain exhaust pipe 10 and passes through a three-axis housing base. After the exit is connected to the air circulation system 13 and the liquid circulating system 17, respectively, after the cycle, the gas pipe 14 is performed, respectively. The water pipe 16 is coupled to the top of a triplet container.

[0062] The outer wall of the triaxial container is a rubber film 5. The acoustic emission system includes an acoustic transmitting sensor 30 and an acoustic emission control system 29; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com