High-quality milk and preparation method thereof

A high-quality, creamy technology, applied in the direction of dairy products, milk preservation, milk preparations, etc., can solve the problems of pathogenic bacteria residue, low safety, loss of nutrients, etc., achieve less loss of active substances and ensure freshness The effect of high speed and high flow retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

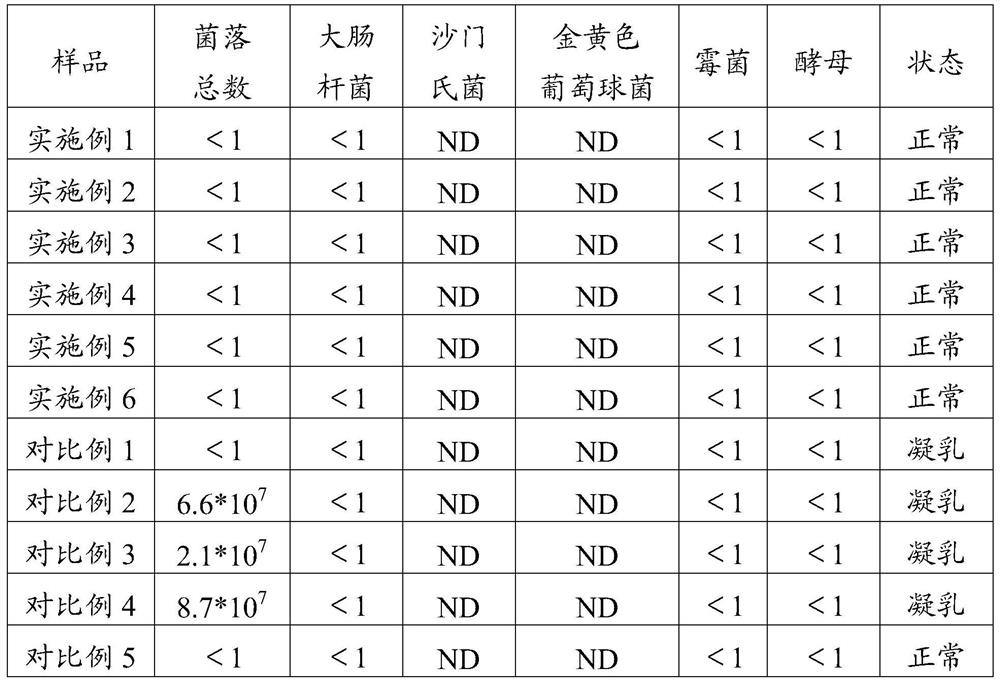

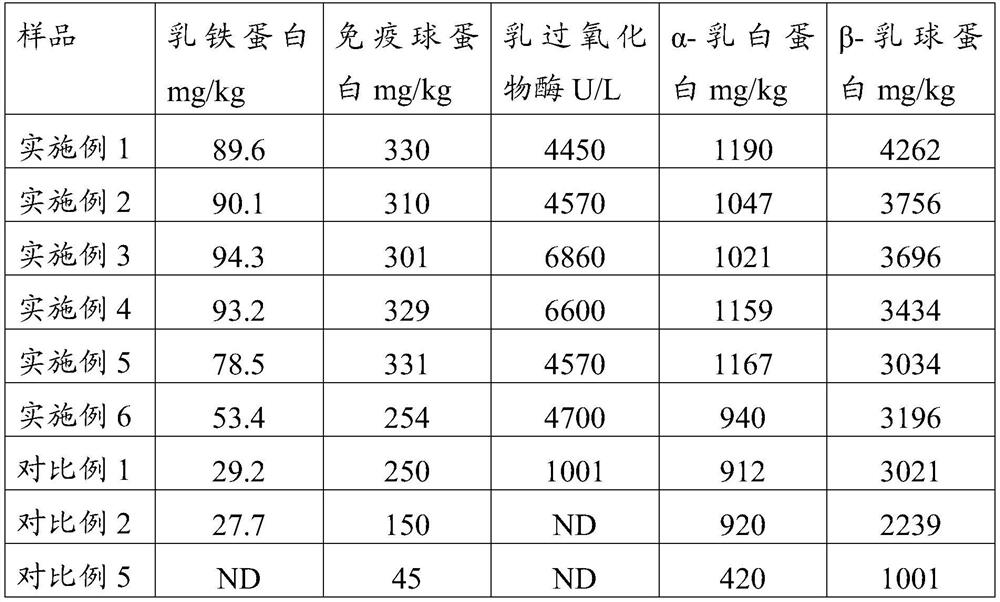

Examples

preparation example Construction

[0032] In a specific embodiment, a method for preparing high-nutrition milk that retains rich nutritional active substances is provided, that is, lactoferrin, immunoglobulin, α-lactalbumin, β-lactoglobulin, milk Peroxidase etc. are preserved, and this preparation method comprises the following steps:

[0033] Step (1) cold cleansing milk:

[0034] Pass the raw milk through cold clean milk (centrifugation) at 2-15°C (such as 2°C, 3°C, 4°C, 5°C, 6°C, 7°C, 8°C, 9°C, 10°C, 12°C, 15°C). Milk cleaner: Tetra Pak, model: OCM-15), to obtain feed liquid, the temperature is preferably 2-10°C.

[0035] By adopting the cold cleaning milk process, the heat load of raw materials is reduced, and the product has low content of heat-sensitive substances and high content of active substances.

[0036] Step (2) degassing:

[0037] The feed liquid obtained in step (1) is preheated and then degassed. Preheating conditions are preferably 55-65°C (eg 55°C, 56°C, 58°C, 60°C, 62°C, 64°C, 65°C), 5-3...

Embodiment 1

[0061] (1) The raw milk is cooled and cleaned at 2°C to obtain a feed liquid;

[0062] (2) Preheat the obtained feed liquid to 55°C after 5s, and degas at 55°C, and the degassing pressure is -0.04Mpa;

[0063] (3) The degassed feed liquid is centrifugally degreased at 55°C to obtain cream and skim milk; the fat content of the obtained cream is 45g / 100g, and the fat content of the obtained skim milk is ≤0.06g / 100g.

[0064] (4) The resulting cream was sterilized at 115°C for 15s and then cooled to 30°C for 10s.

[0065] (5) Remove the spores in the skim milk by using a bacteria-removing separator at 55°C to remove the spores in the skim milk. The separation centrifugal force is 5000g. It is 4bar, and the filtration temperature is 55°C.

[0066] (6) Mix the filtrate of step (4) and step (5) online, the mixing temperature is 55°C, homogenize at 55°C, the homogenization pressure is 230bar, heat up to 72°C after 10s, at 72°C After tube sterilization for 15s, after cooling down t...

Embodiment 2

[0069] (1) The raw milk is cooled and cleaned at 4°C to obtain a feed liquid;

[0070] (2) Preheat the obtained feed liquid to 60°C after 10s, and degas at 60°C, and the degassing pressure is -0.06Mpa;

[0071] (3) The degassed feed liquid is centrifugally degreased at 60°C to obtain cream and skim milk, and the cream can be used for other purposes; the fat content of the obtained skim milk is ≤0.06g / 100g.

[0072] (4) Remove the spores in the skim milk with the obtained skim milk under the condition of 60°C using a sterilizing separator, the separation centrifugal force is 6500g, and the obtained separation liquid is subjected to 0.6 μm MF microfiltration to remove the microorganisms in the skim milk, and the filtration pressure It is 4bar, and the filtration temperature is 60°C.

[0073] (5) Homogenize step (4) at 60°C, the homogenization pressure is 220bar, heat up to 75°C after 15s, keep at 75°C for 15s for plate exchange sterilization, and then pass 25s After cooling do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com