Mixed matrix membrane, preparation method and application thereof

A mixed matrix membrane and mixed dissolution technology, which is applied in the field of material science and gas separation, can solve the problems of reducing the amount of metal-organic framework materials, limiting the wide application of mixed matrix membranes, and irregular morphology, so as to avoid interface defects problems, overcoming interface defects, and ease of industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

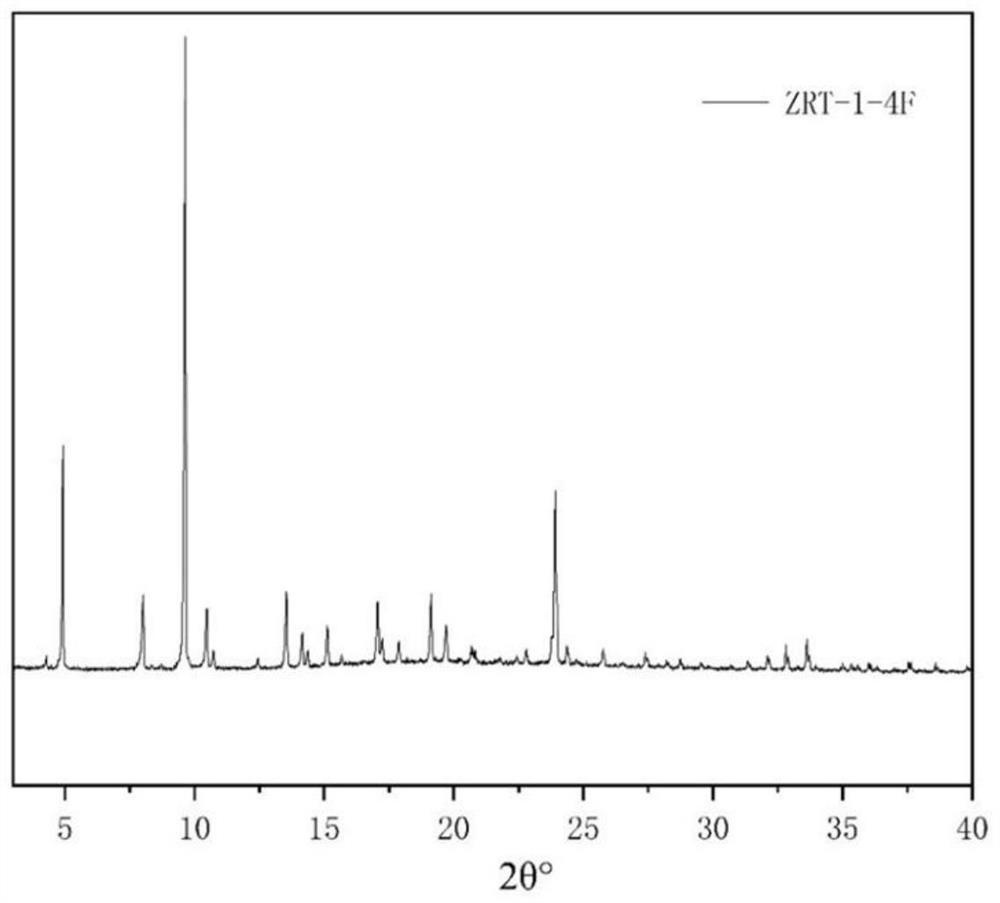

[0034] Example 1 Preparation of porous metal-organic cage complex ZRT-1-4F

[0035] Mix 7.5g of zirconocene, 2.5g of tetrafluoroterephthalic acid and 50mL of N,N-dimethylacetamide (DMA), and sonicate until dissolved; then add 10mL of water, sonicate until the mixture is uniform to obtain a reaction solution; then put Put it in an oven at 65°C for 8 hours to react. After the reaction, the reaction solution was cooled and centrifuged (a large amount of white powder was formed during the reaction), and the obtained solid was washed three times with N,N-diethylformamide (DEF) and dichloromethane successively. , and finally dried under vacuum at 65°C to obtain the porous metal-organic cage complex ZRT-1-4F.

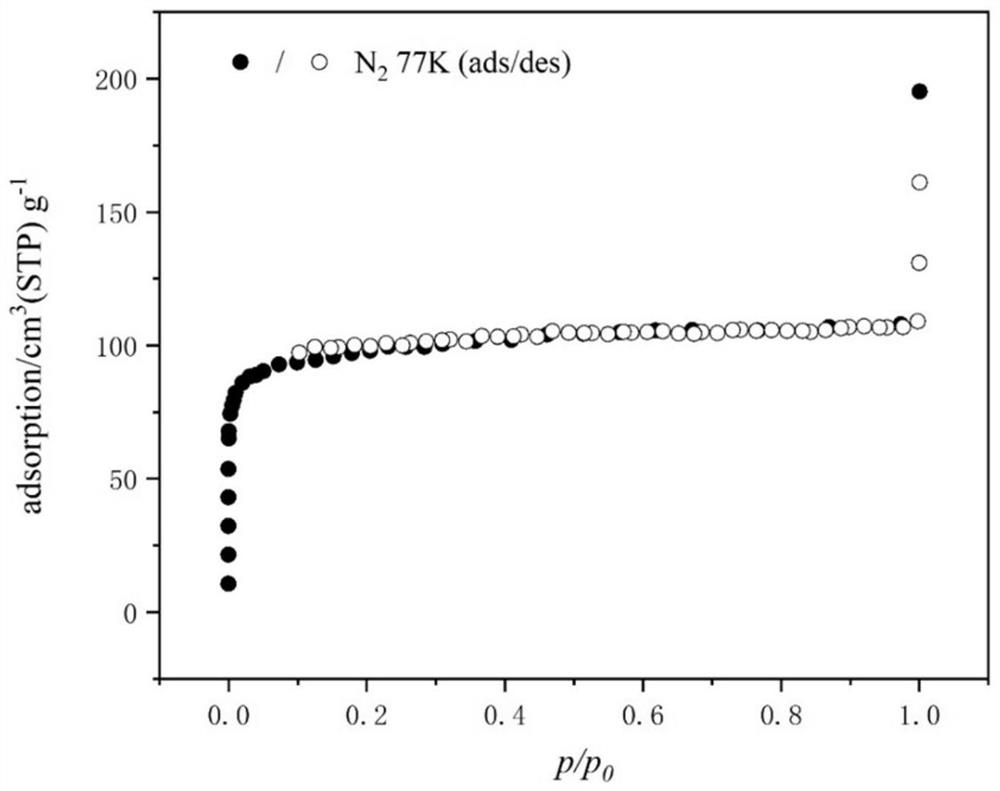

[0036] Result: The N of the porous metal-organic cage complex ZRT-1-4F prepared in this example at 77K 2 Adsorption graph such as figure 1 shown by figure 1 It can be seen that the prepared ZRT-1-4F has a microporous structure.

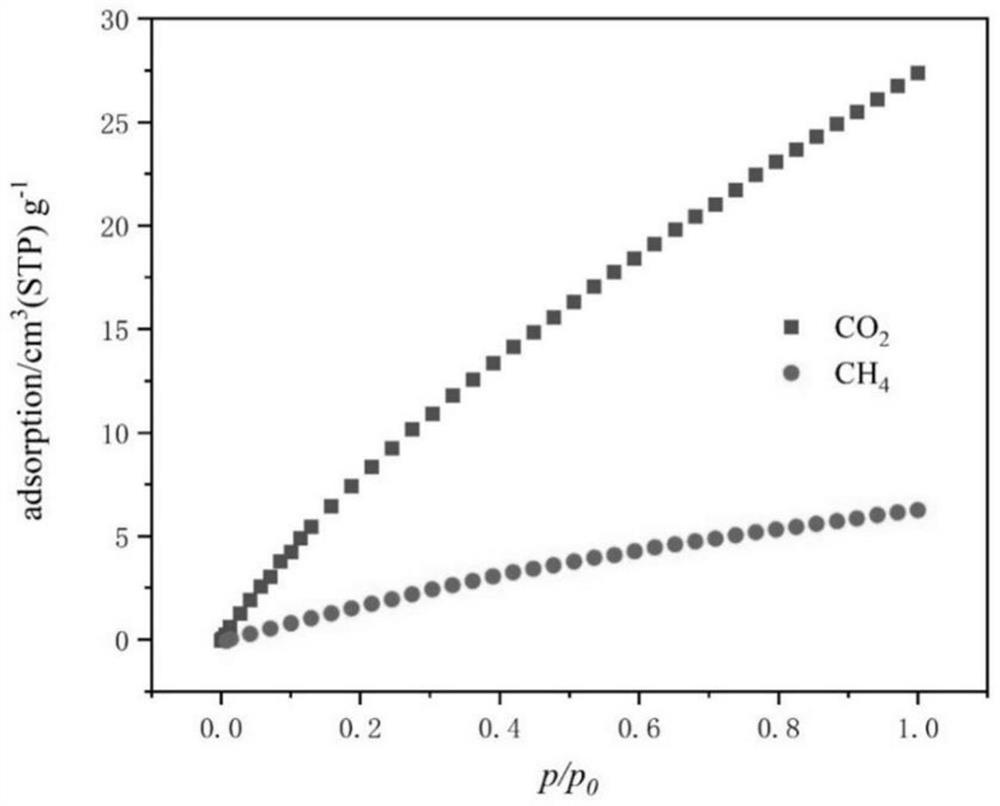

[0037] The CO of the porous metal-organic c...

Embodiment 2

[0039] Example 2 Preparation of porous metal-organic cage complex ZRT-1-4F

[0040] Mix 7.5g of zirconocene, 2.5g of tetrafluoroterephthalic acid and 50mL of N,N-dimethylacetamide (DMA), and sonicate until dissolved; then add 10mL of water, sonicate until the mixture is uniform to obtain a reaction solution; then put Put it in an oven at 55°C for 12 hours to react. After the reaction, the reaction liquid is cooled and centrifuged (a large amount of white powder is formed during the reaction), and the obtained solid is washed three times with N,N-diethylformamide (DEF) and dichloromethane successively. , and finally dried under vacuum at 65°C to obtain the porous metal-organic cage complex ZRT-1-4F.

Embodiment 3

[0041] Example 3 Preparation of porous metal-organic cage complex ZRT-1-4F

[0042] Mix 7.5g of zirconocene, 2.5g of tetrafluoroterephthalic acid and 50mL of N,N-dimethylacetamide (DMA), and sonicate until dissolved; then add 10mL of water, sonicate until the mixture is uniform to obtain a reaction solution; then put Put it into an oven at 85°C for 9 hours to react. After the reaction, the reaction solution was cooled and centrifuged (a large amount of white powder was formed during the reaction), and the obtained solid was washed three times with N,N-diethylformamide (DEF) and dichloromethane in turn. , and finally dried under vacuum at 65°C to obtain the porous metal-organic cage complex ZRT-1-4F.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability coefficient | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com