Composite oxide carrier, hydrofining catalyst as well as preparation method and application thereof

A composite oxide, hydrofining technology, applied in metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve problems such as poor resistance to silicon poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

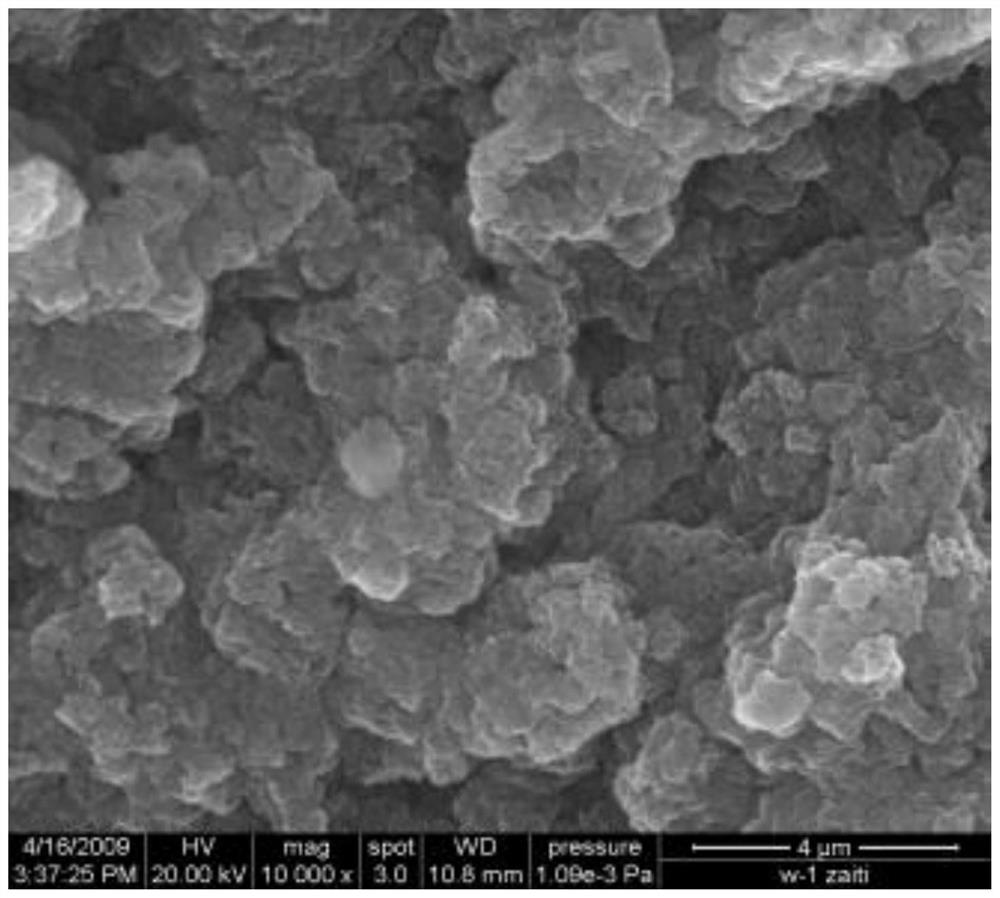

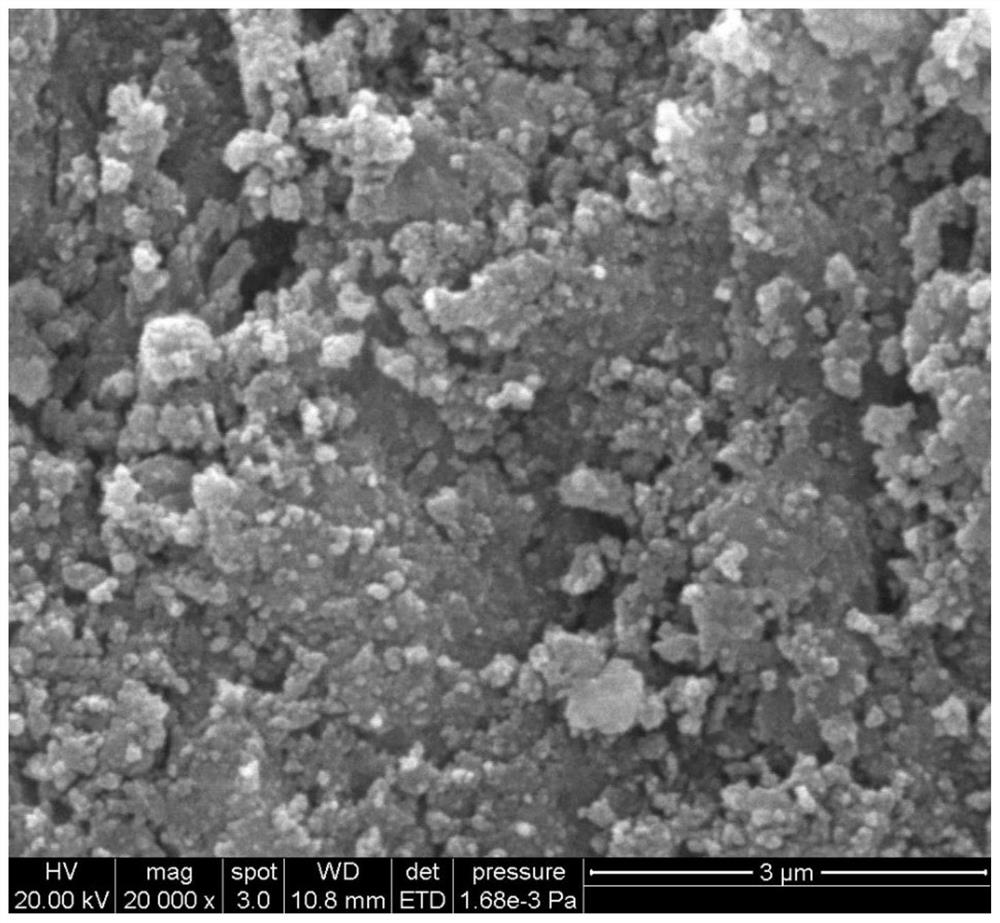

Image

Examples

Embodiment 1

[0080] (A) 35g / L sodium metaaluminate aqueous solution (with Al 2 o 3 The calculated sodium metaaluminate concentration is 35g / L) after stirring for 30min at 55°C, 45% by volume of CO 2 (The rest is air) until the end point is pH=9, and then aged at this temperature for 3h. The aged mixture was poured into a filter, washed with deionized water for 30 minutes at a temperature of 60° C., washed repeatedly for 3 times, and filtered to obtain filter cake A1.

[0081] (B) After mixing tetraethyl titanate and ammonia water, the pH was kept at 9.5 to obtain a mixed solution B1.

[0082] (C) Put the filter cake A1 into the mixed liquid B1, keep it at a temperature of 70°C for 1h, then put it into a filter, wash it with deionized water for 30min, the washing temperature is 20°C, wash it with water 5 times, filter it, and extrude it. Dry at 110° C. for 3 h, and then calcinate at 550° C. for 3 h to prepare composite oxide carrier A1.

[0083] The composite oxide support A1, including...

Embodiment 2

[0086] (A) 50g / L sodium metaaluminate aqueous solution (with Al 2 o 3 The concentration of sodium metaaluminate is 50g / L) After stirring at 35°C for 60min, 35% by volume of CO 2 (The rest is air) to the end point pH = 10.5, and then aged at this temperature for 4 hours. Put the aged mixture into a filter, wash with deionized water for 30 minutes at a temperature of 50° C., wash repeatedly for 3 times, and filter to obtain filter cake A2.

[0087] (B) After mixing titanium sulfate and sodium hydroxide aqueous solution, the pH was kept at 9 to obtain a mixed solution B2.

[0088] (C) Put the filter cake A2 into the mixed liquid B2, keep it at a temperature of 80°C for 1.5h, then put it into a filter, wash it with deionized water for 30min at a temperature of 30°C, wash it 5 times, filter, and extrude , dried at 120° C. for 4 h, and then calcined at 550° C. for 4 h to obtain a composite oxide carrier A2.

[0089] The composite oxide support A2, including TiO 2 and Al 2 o 3...

Embodiment 3

[0092] (a) preparation concentration is 26.68g / 100mL ammonium molybdate tetrahydrate (every 100mL deionized water contains 26.68g ammonium molybdate tetrahydrate), and then adding 5mL of concentration is 14% by weight of ammonia so that ammonium molybdate tetrahydrate is fully dissolved 100g of the composite oxide carrier A1 prepared in Example 1 was taken, impregnated at room temperature for 2h, filtered, dried at 110°C overnight, then calcined at 300°C for 1h, and then calcined at 550°C for 3h to obtain the catalyst precursor YB-1.

[0093] (b) Then the catalyst precursor YB-1 is impregnated with a solution of cobalt nitrate hexahydrate with a concentration of 22.34g / 100mL, impregnated at room temperature for 2h, filtered, dried overnight at 110°C, and then calcined at 550°C for 4h to obtain Hydrofining catalyst MCAT-1.

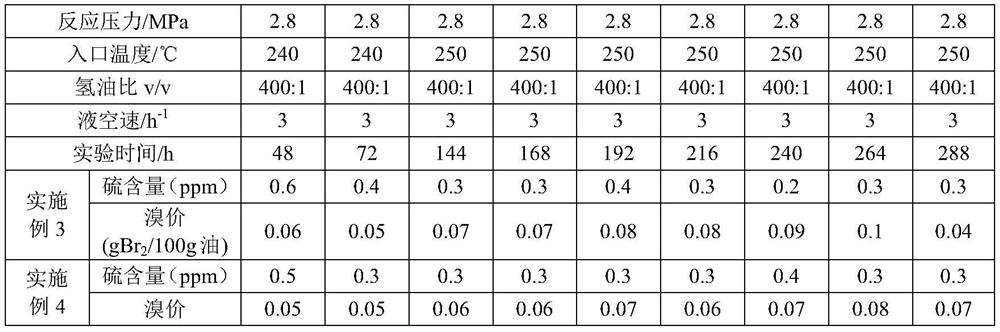

[0094] Based on the total weight of the hydrotreating catalyst MCAT-1, TiO 2 The content of the composite oxide support is 15% by weight, MoO 3 The conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com