Catalyst as well as preparation method and application thereof

A catalyst, alumina technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as poor resistance to silicon poisoning and prolonged operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

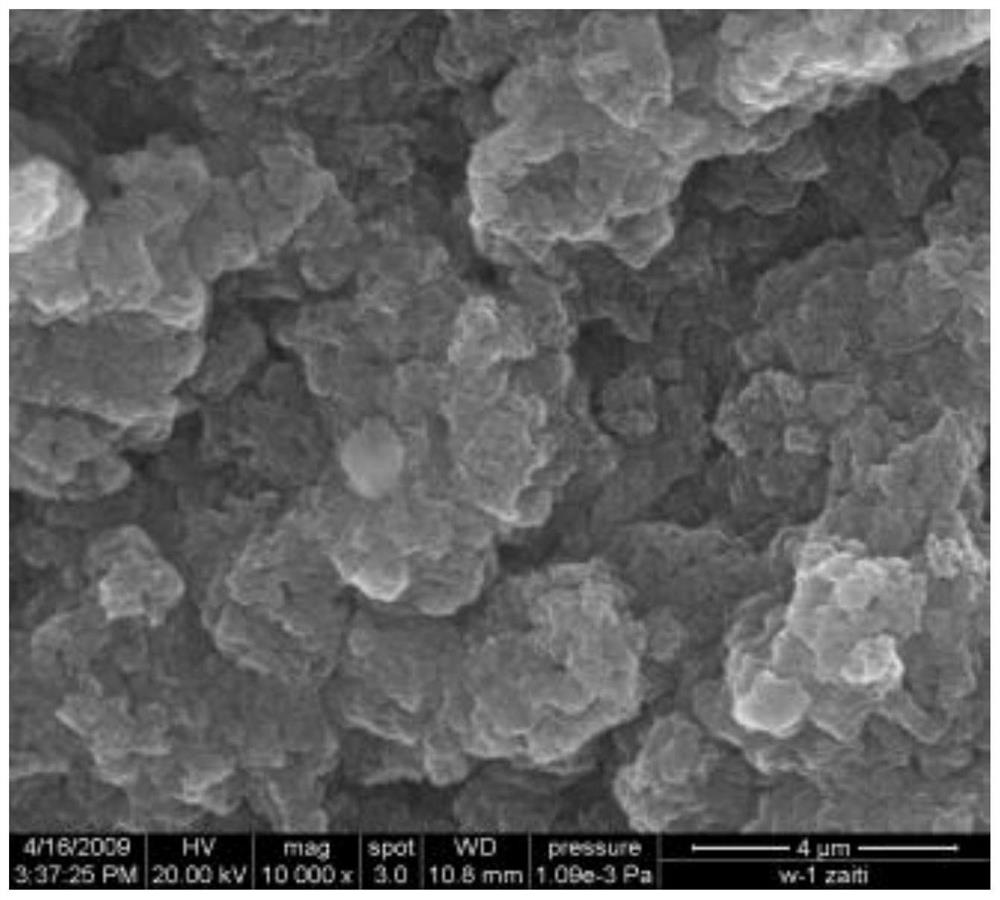

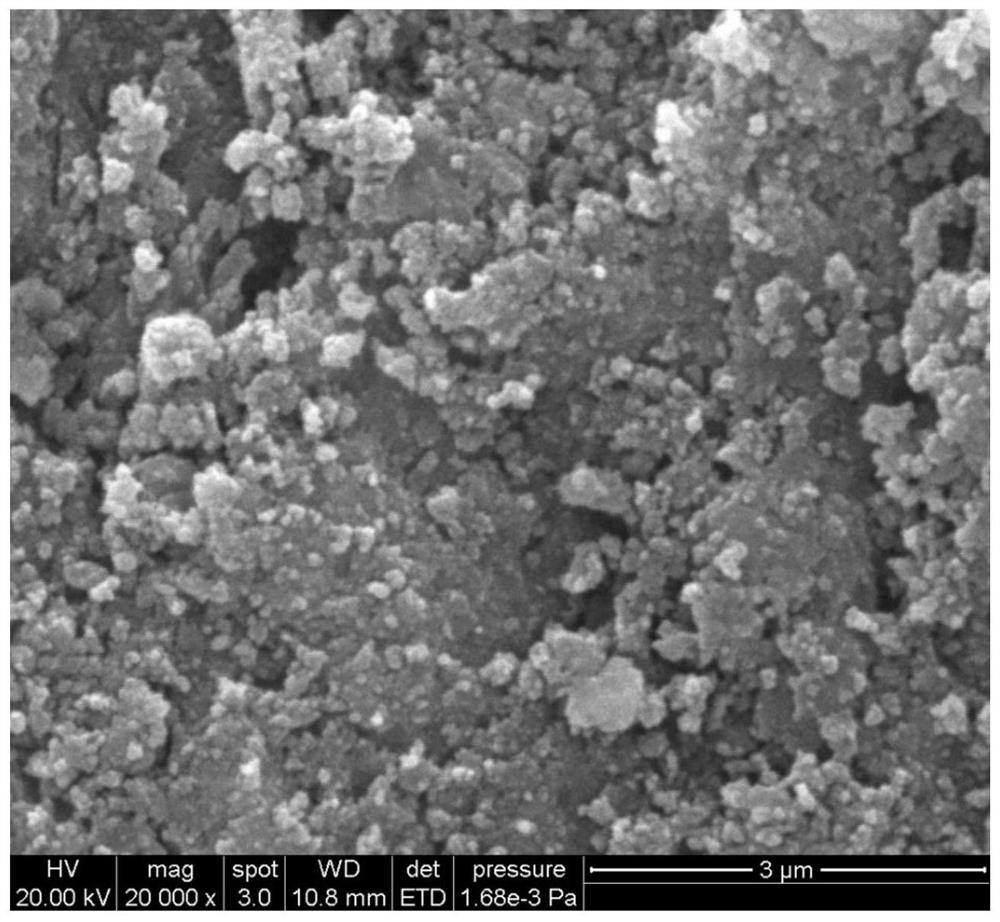

Image

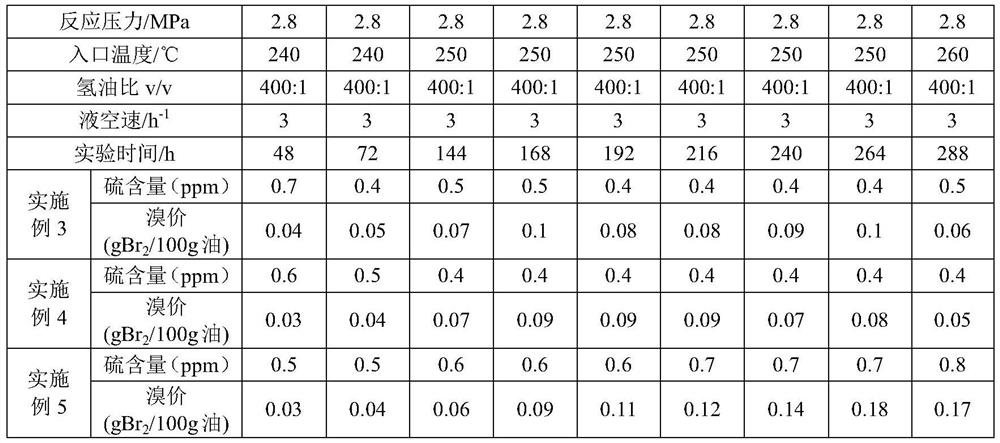

Examples

Embodiment 1

[0075] (A) After stirring 35g / L sodium metaaluminate aqueous solution (the concentration of sodium metaaluminate calculated as alumina is 35g / L) at 55°C for 30min, 45% by volume of CO 2 (The rest is air) until the end point is pH=9, and then aged at this temperature for 3h. The aged mixture was poured into a filter, washed with deionized water for 30 minutes at a temperature of 60° C., washed repeatedly for 3 times, and filtered to obtain filter cake A1.

[0076] (B) After mixing tetraethyl titanate and ammonia water, the pH was kept at 9.5 to obtain a mixed solution B1.

[0077] (C) Put the filter cake A1 into the mixed liquid B1, keep it at a temperature of 70°C for 1h, then put it into a filter, wash it with deionized water for 30min, the washing temperature is 20°C, wash it with water 5 times, filter it, and extrude it. Drying at 110° C. for 3 h, and then calcining at 550° C. for 3 h to prepare alumina-titania composite oxide support A1.

[0078] The composite oxide carr...

Embodiment 2

[0081] (A) After stirring 50g / L sodium metaaluminate aqueous solution (the concentration of sodium metaaluminate calculated as alumina is 50g / L) at 35°C for 60min, 35% by volume of CO 2 (The rest is air) to the end point pH = 10.5, and then aged at this temperature for 4 hours. Put the aged mixture into a filter, wash with deionized water for 30 minutes at a temperature of 50° C., wash repeatedly for 3 times, and filter to obtain filter cake A2.

[0082] (B) After mixing titanium sulfate and sodium hydroxide aqueous solution, the pH was kept at 9 to obtain a mixed solution B2.

[0083] (C) Put the filter cake A2 into the mixed liquid B2, keep it at a temperature of 80°C for 1.5h, then put it into a filter, wash it with deionized water for 30min at a temperature of 30°C, wash it 5 times, filter, and extrude , dried at 120° C. for 4 h, and then calcined at 550° C. for 4 h to obtain alumina-titania composite oxide carrier A2.

[0084] The composite oxide carrier A2 includes tit...

Embodiment 3

[0087] (1) Dissolve 7.5g of nickel nitrate and 6.5g of diammonium hydrogen phosphate in 20g of deionized water to obtain a yellow precipitate, add nitric acid dropwise to adjust the pH value to 3, the precipitate dissolves and becomes a green transparent solution, add 8.25g to it for implementation The alumina-titania composite oxide carrier A1 prepared in Example 1 was impregnated at room temperature for 2 hours, filtered, dried at 120° C. for 5 hours, and then calcined at 550° C. for 4 hours to obtain catalyst A1.

[0088] Based on the total weight of catalyst A1, the content of alumina-titania composite oxide is 80.5% by weight, Ni 2 The P content was 19.5% by weight. The catalyst has a pore volume of 0.38mL / g and a specific surface area of 195m 2 / g.

[0089] (2) First use hydrogen gas with a hydrogen-to-oil ratio of 200, carry out reduction at 650°C for 2 hours, and then use 1% by weight of CS at 300°C 2 The cyclohexane solution was sulfurized for 8 hours, and after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com