Preparation method of metal-doped bismuth layered oxide and application of metal-doped bismuth layered oxide in electrocatalytic reduction of CO2

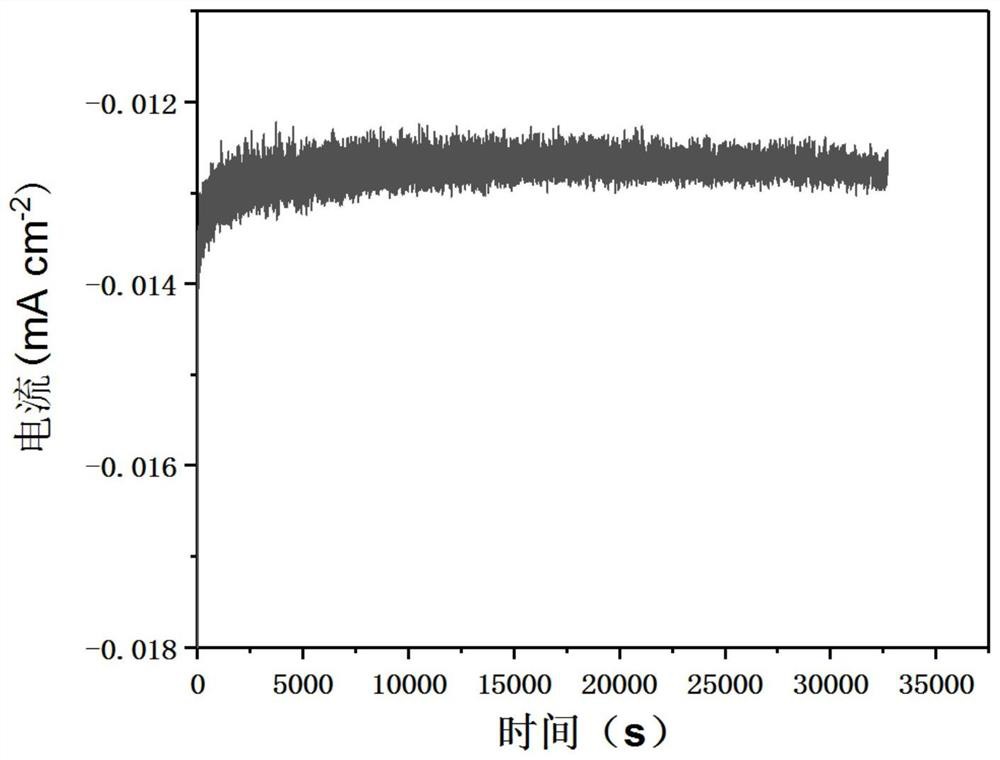

A metal-doped, bismuth-layered technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the unstable structure and performance of layered bismuth oxides to achieve the effects of promoting enrichment reduction, regulating charge distribution, and large electrochemical active area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

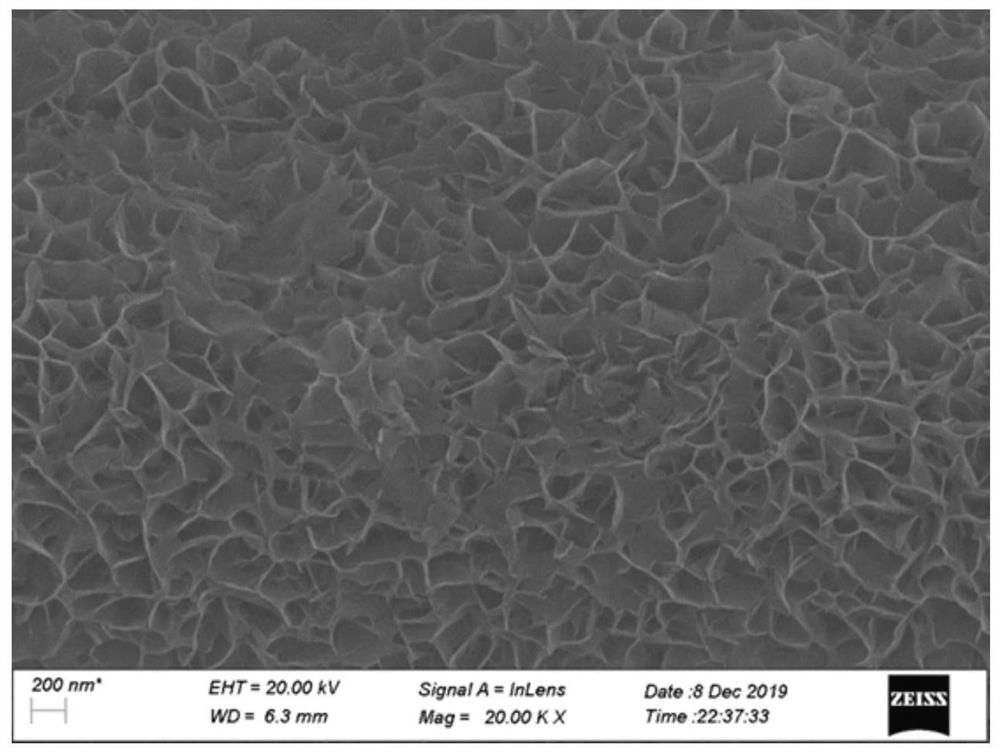

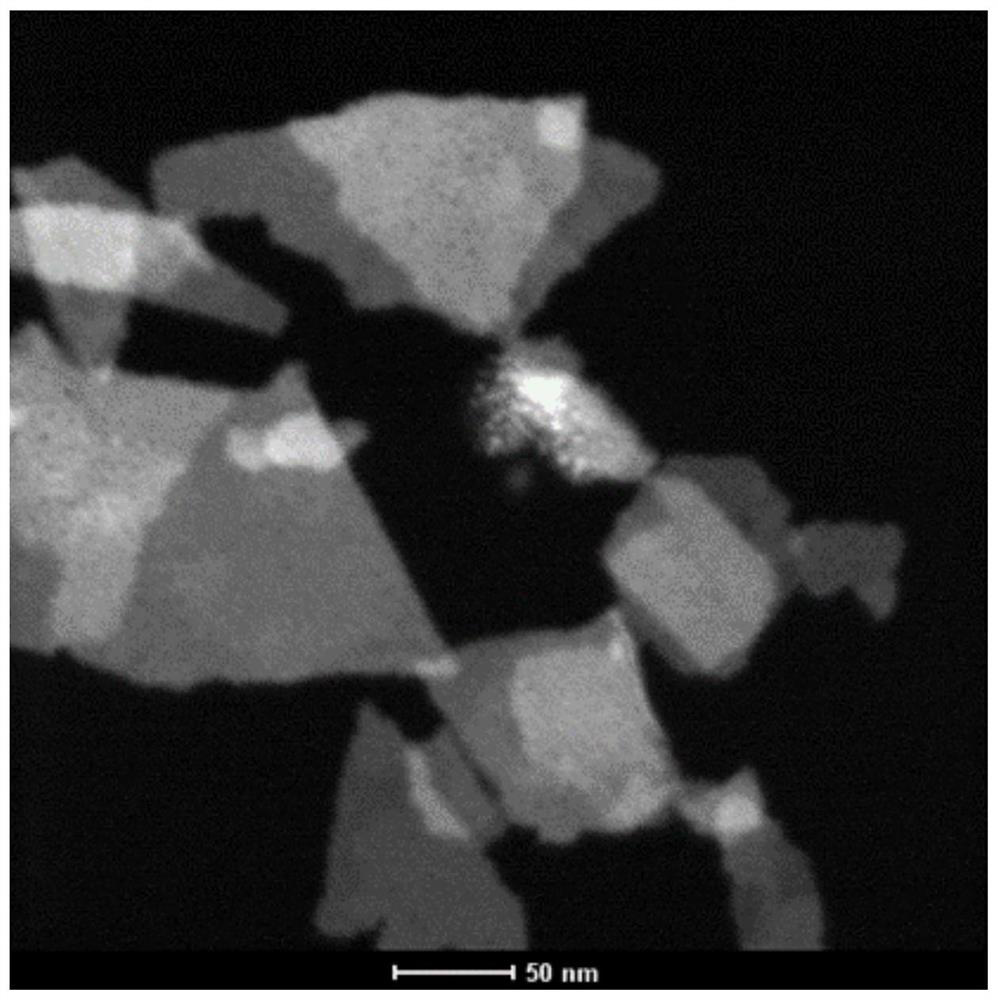

[0049] 1). Synthesis of silver-doped layered bismuth oxide (nanosheet array electrode) supported on carbon cloth:

[0050] a: Soak a properly cut carbon cloth in 0.5mol / L potassium permanganate solution for half an hour, take it out, clean it with deionized water and dry it.

[0051] b: Dissolve 25mg of bismuth nitrate in 3mL of ethylene glycol to obtain a completely transparent solution, then add 6mL of ethanol, stir for 10min, and place 1.5×1cm 2 The carbon cloth was immersed in the solution for 3 h, and then dried in an oven at 60 °C for 10 min to form a bismuth oxide seed layer. The immersion-drying step was repeated 3 times, thereby achieving uniform modification of bismuth oxide.

[0052] c: Dissolve 1g of bismuth nitrate and 0.5g of silver nitrate in 17mL of ethylene glycol to obtain a completely transparent solution, then add 34mL of ethanol and stir well; The carbon cloth was soaked in an autoclave, and after hydrothermal growth at 160°C for 6 hours, the carbon clot...

Embodiment 2

[0062] 1). Synthesis of cobalt-doped layered bismuth oxide (nanosheet array electrode) supported on foamed copper:

[0063] a: Wash the appropriately cut foam copper in ethanol, 35% dilute sulfuric acid, and deionized water for half an hour, take it out and dry it.

[0064] b: 10 mg of bismuth nitrate was dissolved in 3 mL of ethylene glycol, the copper foam was immersed in the solution for 1 h, and then dried in an oven at 60° C. for 10 min to form a bismuth oxide seed layer. The immersion-drying step was repeated 3 times to achieve uniform modification of bismuth oxide.

[0065] c: Dissolve 1.5g of bismuth nitrate and 1g of cobalt chloride in a mixed solution of 17mL of ethylene glycol and 34mL of ethanol (of course, ethanol can also be added later), and transfer the mixed solution to an autoclave. Soak the copper foam modified with bismuth oxide in a high-pressure reactor, take it out after hydrothermal growth at 150°C for 5 hours, rinse with water and ethanol to remove ot...

Embodiment 3

[0071] 1). Synthesis of carbon paper-supported copper-doped layered bismuth oxide (nanosheet array electrode):

[0072] a: Soak the properly cut carbon paper in 0.5mol / L potassium permanganate solution for half an hour, take it out, clean it with deionized water and dry it.

[0073] b: Dissolve 30mg of bismuth nitrate in 6mL of ethanol, after stirring for 10min, put 1.5×1cm 2 The carbon paper was immersed in the solution for 2 h, and then dried in an oven at 60 °C for 10 min to form a bismuth oxide seed layer. The immersion-drying step was repeated 3 times to achieve uniform modification of bismuth oxide.

[0074] c: Dissolve 1g of bismuth nitrate and 0.5g of copper sulfate in a mixed solution of 15mL of ethylene glycol and 30mL of ethanol, and stir evenly; In the kettle, after hydrothermal growth at 160°C for 8 hours, take it out, rinse with water and ethanol to remove surface residues, and dry at 80°C.

[0075] 2). Carbon paper-supported copper-doped layered bismuth oxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com