Production process and application of high-voltage armored thermocouple protection device for hydrogenation reactor

An armored thermocouple, hydrogenation reactor technology, applied in chemical instruments and methods, refining to remove heteroatoms, chemical/physical processes, etc. Stability and other issues, to achieve the effect of improving application assembly efficiency, improving stability, and preventing protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below we combine Figure 1-9 To further describe the present invention in detail, the following examples are used to illustrate the present invention, but do not limit the scope of the present invention.

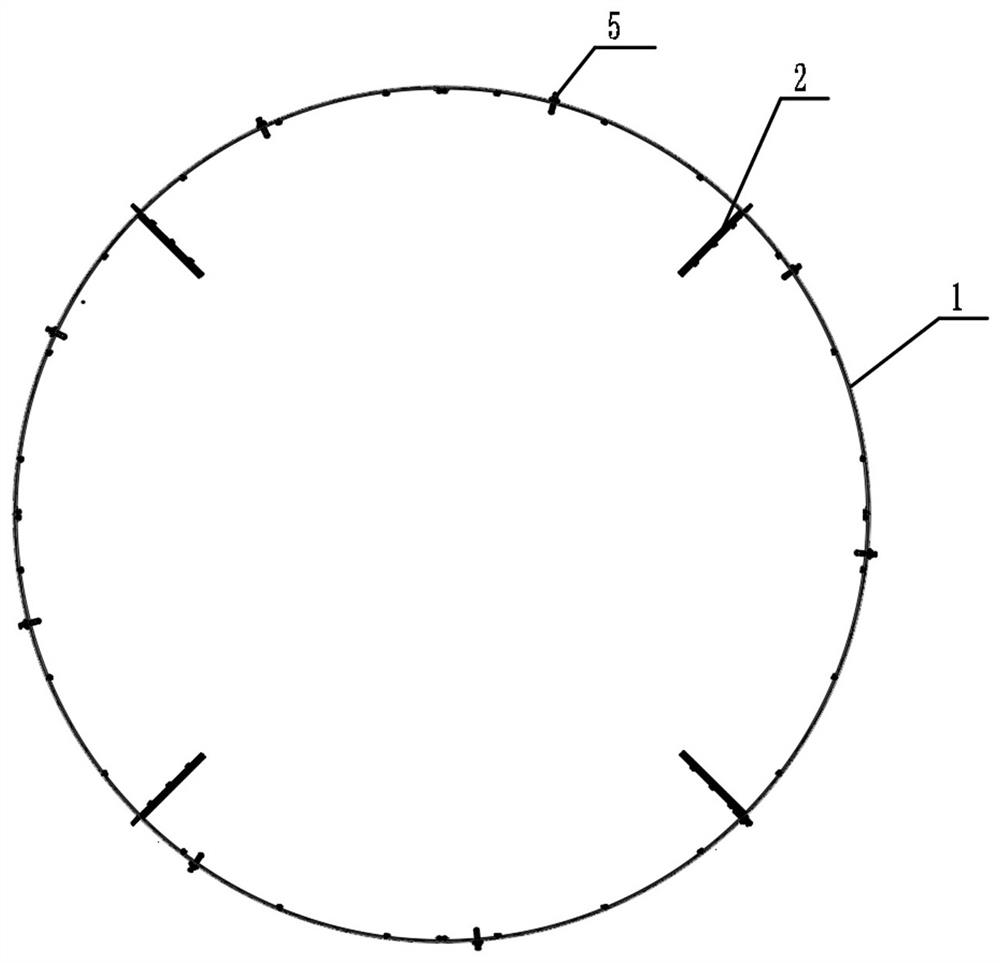

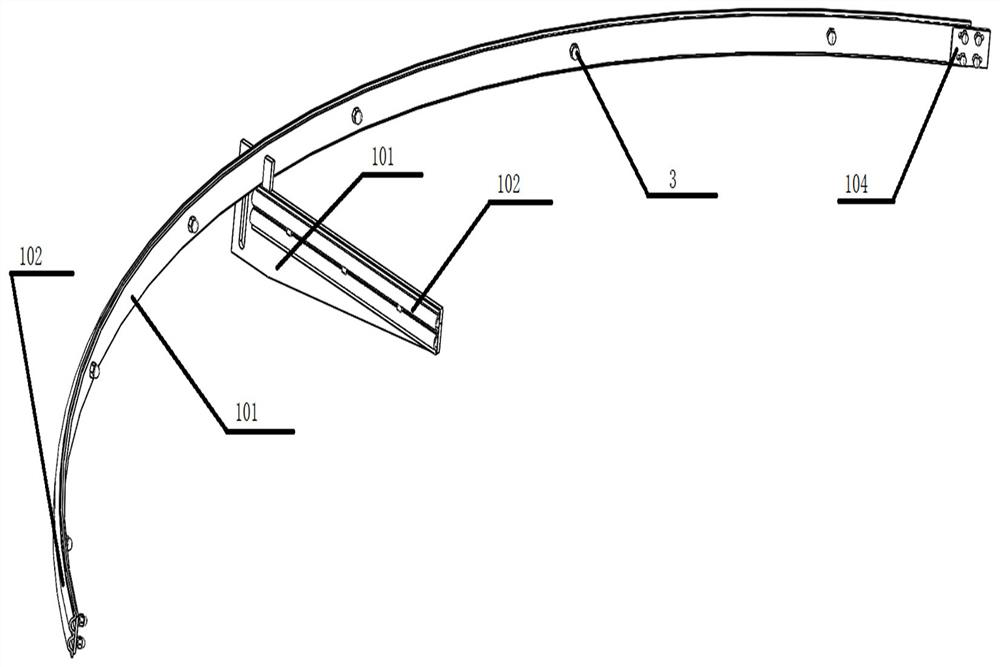

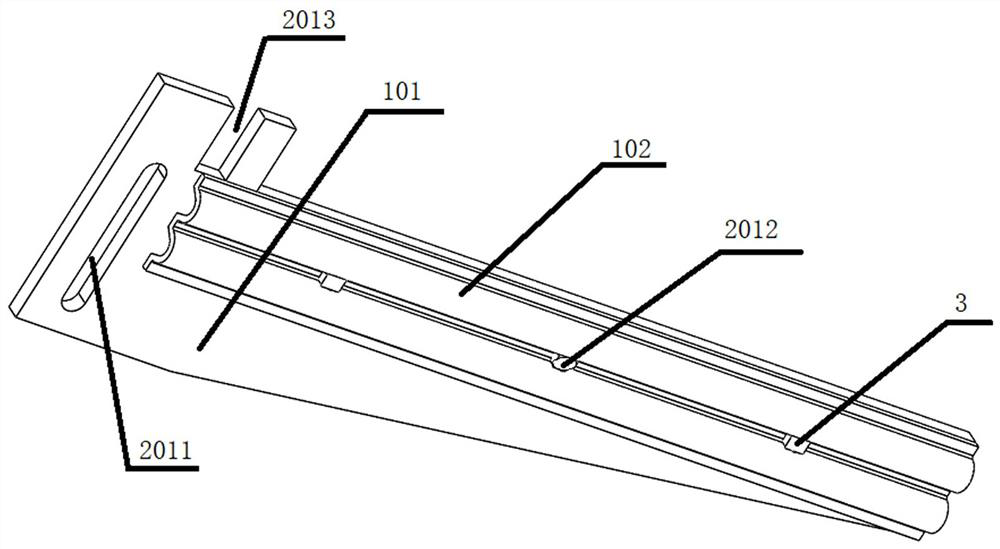

[0037] see attached Figure 1-9 , a production process of a high-pressure armored thermocouple protection device for a hydrogenation reactor of the present invention, during production, firstly, according to the shape and structure of the inner wall of the hydrogenation reactor, first design the protection mechanism 1 and the support mechanism for installing the protection mechanism The structure of 2; taking the shape of the inner wall of the circular hydrogenation reactor as an example, the protective mechanism 1 and the supporting mechanism 2 for installing the protective mechanism are designed to be arc-shaped installations corresponding to the inner wall during manufacture, and the protective mechanism 1 and the supporting mechanism 2 are designed. Both include ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com