Reusable non-woven fabric composite fabric and processing technology

A technology of composite fabrics and processing technology, applied in the field of protective clothing fabrics, can solve the problems of poor air permeability, no enhanced air permeability of the base fabric, high hydrostatic pressure, etc., and achieve poor heat aging resistance, low water absorption, and small afterburning time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

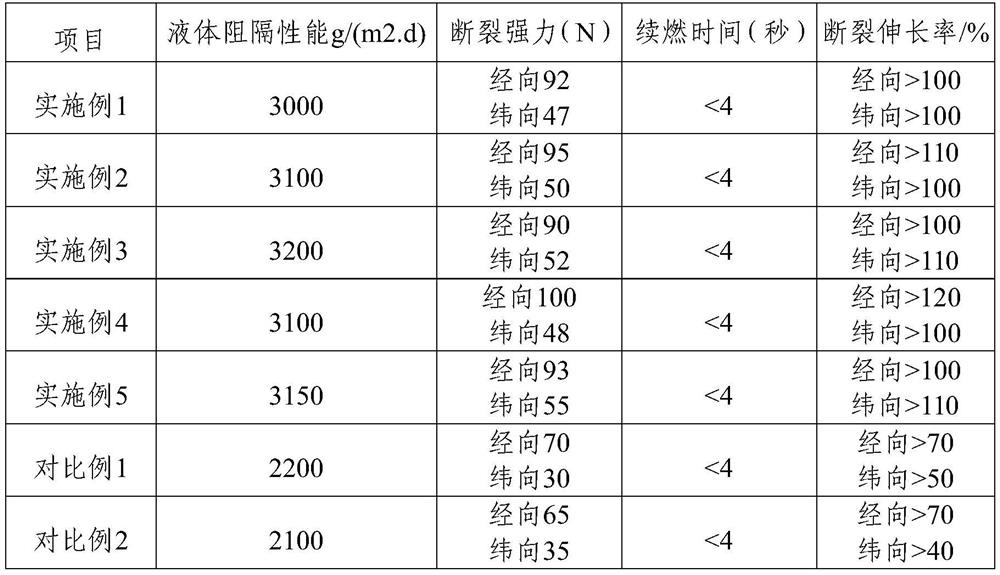

Examples

Embodiment 1

[0018] The outer fabric includes two layers of non-woven fabric, 85 parts of polylactide, 5 parts of citric acid modified polypropylene ether, and 2 parts of aramid. At least one layer of non-woven fabric is coated with anhydrous adhesive, the excipient methyl cellulose adheres to the surface of the non-woven fabric, and the two layers of non-woven fabric are pasted to sandwich the excipient between the two layers of non-woven fabric Between, 50 DEG C blast drying; The inner layer fabric comprises non-woven fabric layer and the polyethylene resin film layer that thermocompression fusion is compounded on the outer surface of one end of said non-woven fabric, and 70 parts by weight of polyethylene resin, 10 parts by weight Add 1 part kapok fiber and 0.5 part lubricant into the mixer to stir and disperse evenly, then add 1 part decontamination agent and 5 parts N,N-methylenebisacrylamide crosslinking agent, and mix evenly in the internal mixer, and send Put it into an extrusion c...

Embodiment 2

[0021] The outer fabric includes two layers of non-woven fabric, 85 parts of polylactide, 10 parts of citric acid modified polypropylene ether, and 6 parts of aramid. At least one layer of non-woven fabric is coated with anhydrous adhesive, the excipient methyl cellulose adheres to the surface of the non-woven fabric, and the two layers of non-woven fabric are pasted to sandwich the excipient between the two layers of non-woven fabric Between, 55 ℃ blast drying; The inner fabric layer comprises the non-woven fabric layer and the polyethylene resin film layer that heat-compression fusion is compounded on the outer surface of one end of the non-woven fabric, 84 parts by weight of polyethylene resin, 15 parts by weight Add 1 part of kapok fiber and 1 part of lubricant into the mixer to stir and disperse evenly, then add 3 parts of decontamination agent and 10 parts of triallyl isocyanurate cross-linking agent, and banbury evenly in the internal mixer, and send it into the Calende...

Embodiment 3

[0024] The outer fabric includes two layers of non-woven fabric, 85 parts of polylactide, 8 parts of citric acid modified polypropylene ether, and 5 parts of aramid. At least one layer of non-woven fabric is coated with anhydrous adhesive, the excipient methyl cellulose adheres to the surface of the non-woven fabric, and the two layers of non-woven fabric are pasted to sandwich the excipient between the two layers of non-woven fabric Between, 60 ℃ blast drying; The inner layer fabric comprises non-woven fabric layer and the polyethylene resin film layer that thermocompression fusion is compounded on the outer surface of one end of the non-woven fabric, 75 parts by weight of polyethylene resin, 10 1 part of kapok fiber and 0.75 part of lubricant are added to the mixer to stir and disperse evenly, then add 2 parts of decontamination agent and 5 parts of 1,6-hexanediol diacrylate cross-linking agent, and banbury evenly in the internal mixer. Put it into an extrusion calender and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Continue burning | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com