Preparation method for manufacturing building hollow bricks by using mineral tailings

A technology for tailings slag and hollow bricks is applied in the field of hollow bricks, which can solve the problems of easy fracture and poor toughness of hollow bricks, and achieve the effects of increasing production quality, improving molding effect and improving practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

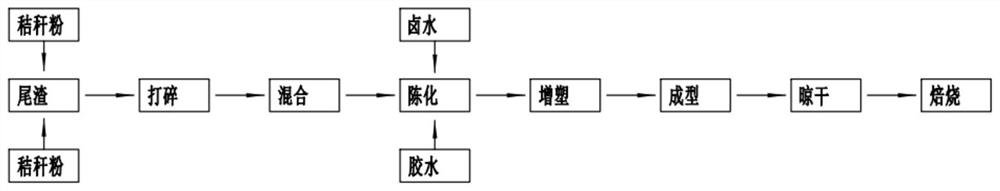

[0034] A preparation method for manufacturing building hollow bricks using mining tailings slag, comprising the following steps:

[0035] Include the following steps:

[0036] S1. Ingredients: add a certain amount of straw powder and white cement to the mining waste;

[0037] S2. Grinding: put the step S1 into the mixer and pulverizer for stirring and mixing;

[0038] S3. Aging: put the materials after the stirring in step S2 into the aging bin, and add a certain proportion of brine and glue for stacking;

[0039] S4. Plasticizing: adding a certain amount of glass fiber powder and calcium carbonate powder to step S3, and then rolling and crushing;

[0040] S5. Molding: put the material in step S4 into the inside of the extruder for extrusion molding;

[0041] S6. Inspection: check the materials in step S5, put the unqualified materials into the extruder again for extrusion, and send the qualified materials into the next step by cart;

[0042] S7. Drying: the qualified mate...

Embodiment 2

[0054] A preparation method for manufacturing building hollow bricks using mining tailings slag, comprising the following steps:

[0055] Include the following steps:

[0056] S1. Ingredients: add a certain amount of straw powder and white cement to the mining waste;

[0057] S2. Grinding: put the step S1 into the mixer and pulverizer for stirring and mixing;

[0058] S3. Aging: put the materials after the stirring in step S2 into the aging bin, and add a certain proportion of brine and glue for stacking;

[0059] S4. Plasticizing: adding a certain amount of glass fiber powder and calcium carbonate powder to step S3, and then rolling and crushing;

[0060] S5. Molding: put the material in step S4 into the inside of the extruder for extrusion molding;

[0061] S6. Inspection: check the materials in step S5, put the unqualified materials into the extruder again for extrusion, and send the qualified materials into the next step by cart;

[0062] S7. Drying: the qualified materi...

Embodiment 3

[0074] A preparation method for manufacturing building hollow bricks using mining tailings slag, comprising the following steps:

[0075] Include the following steps:

[0076] S1. Ingredients: add a certain amount of straw powder and white cement to the mining waste;

[0077] S2. Grinding: put the step S1 into the mixer and pulverizer for stirring and mixing;

[0078] S3. Aging: put the materials after the stirring in step S2 into the aging bin, and add a certain proportion of brine and glue for stacking;

[0079] S4. Plasticizing: adding a certain amount of glass fiber powder and calcium carbonate powder to step S3, and then rolling and crushing;

[0080] S5. Molding: put the material in step S4 into the inside of the extruder for extrusion molding;

[0081] S6. Inspection: check the materials in step S5, put the unqualified materials into the extruder again for extrusion, and send the qualified materials into the next step by cart;

[0082] S7. Drying: the qualified mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com