Large-scale thin-wall X-ray focusing mirror automatic replication device

A copying device and X-ray technology, which is applied in the field of X-ray focusing mirror processing, can solve the problems of inability to guarantee the consistency of mass replication process, inability to meet mass production, time-consuming and labor-intensive, etc., so as to ensure process consistency and facilitate copying of workpieces. , the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The lens and the mirror housing are the same part

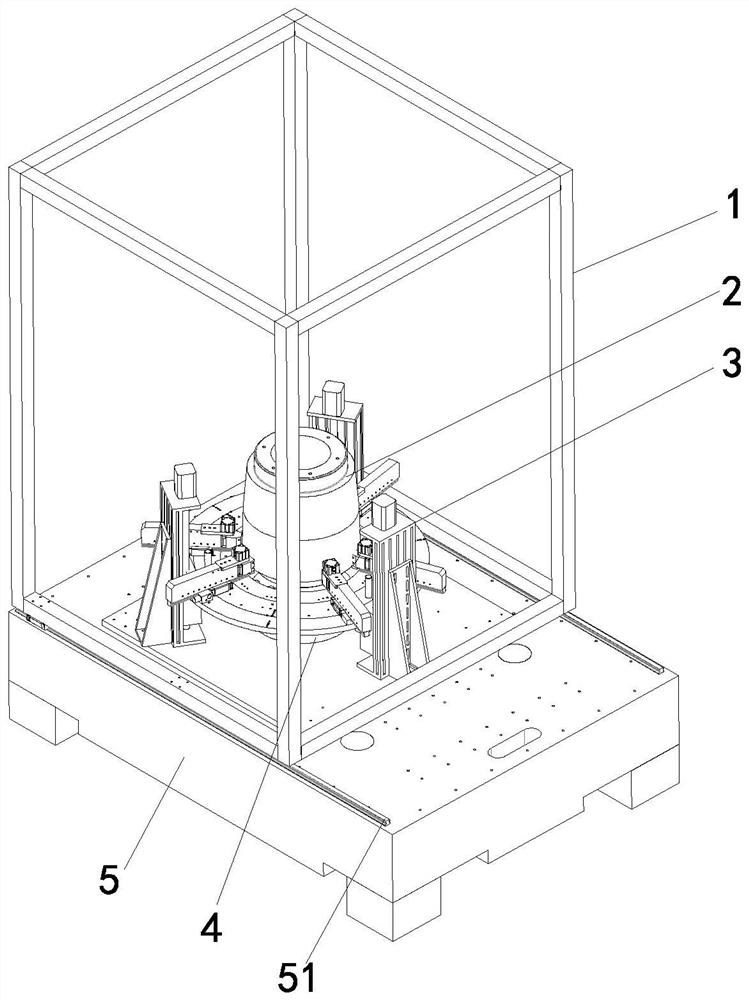

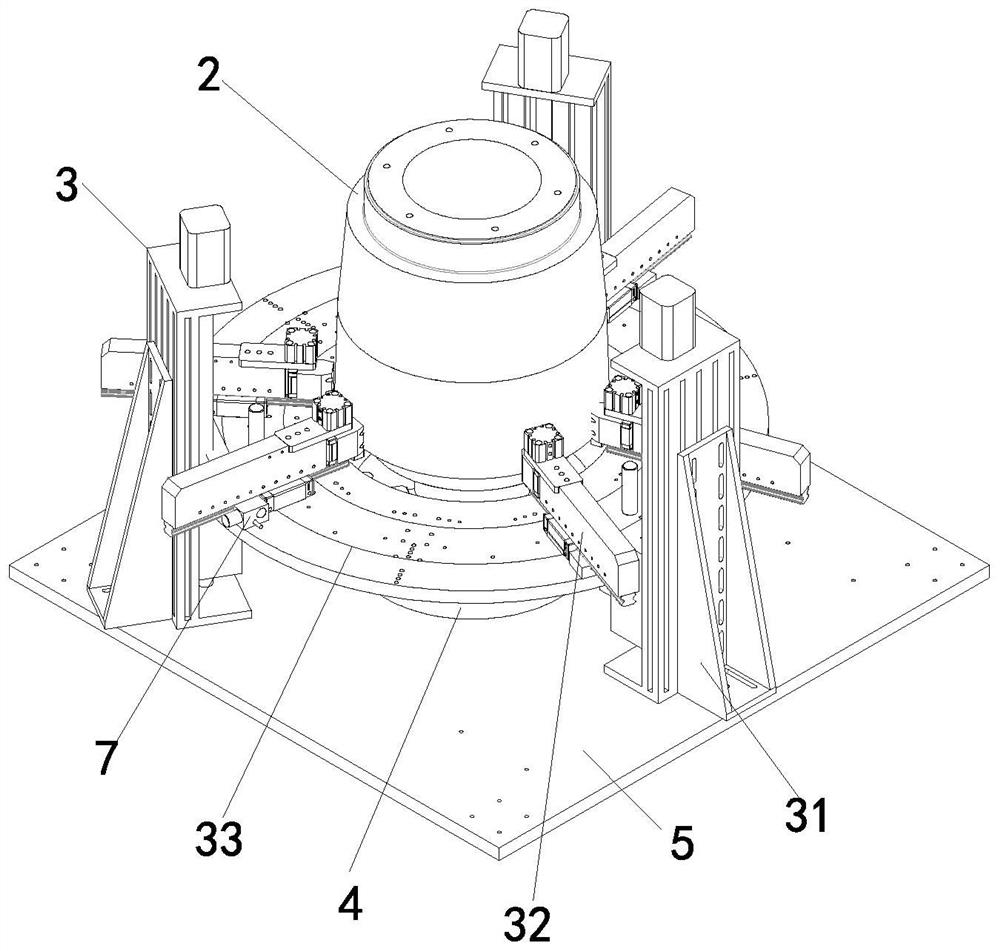

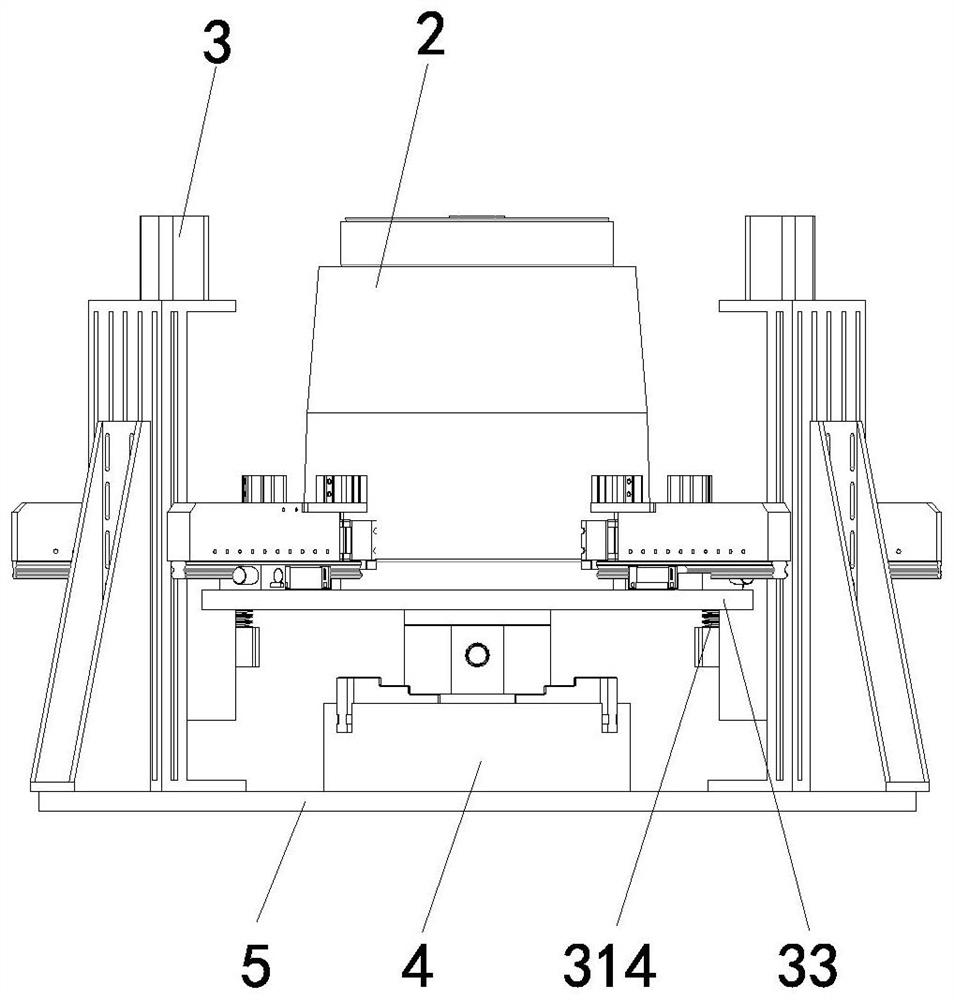

[0022] Specific implementation mode one: refer to Figure 1 to Figure 7 Describe this embodiment, this embodiment provides large-scale thin-walled X-ray focusing mirror automatic duplication device, comprises sealing cover 1, separating mechanism 3, clamping mechanism 4, base 5 and liquid nitrogen circulation device 6; Said separating mechanism 3. The clamping mechanism 4 and the sealing cover 1 are installed on the base 5, the mandrel mold 2 is installed on the clamping mechanism 4, the separation mechanism 3 is used to separate the mirror housing on the mandrel mold 2, and the sealing The cover 1 is set on the mandrel mold 2, the separation mechanism 3, and the clamping mechanism 4 so that the three are in a sealed environment, and the liquid nitrogen circulation device 6 injects liquid nitrogen into the mandrel mold 2 and injects nitrogen gas into the sealing cover 1, It is used for the cold shrinkage of the mandre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com