Three-dimensional trench gate charge storage type IGBT and manufacturing method thereof

A technology of charge storage and charge storage layer, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc. It can solve the problems of poor short-circuit safety working ability of IGBT, increase of device switching loss, and degradation of device breakdown voltage. Achieve the effects of eliminating adverse effects, reducing switching losses, and improving breakdown voltage and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

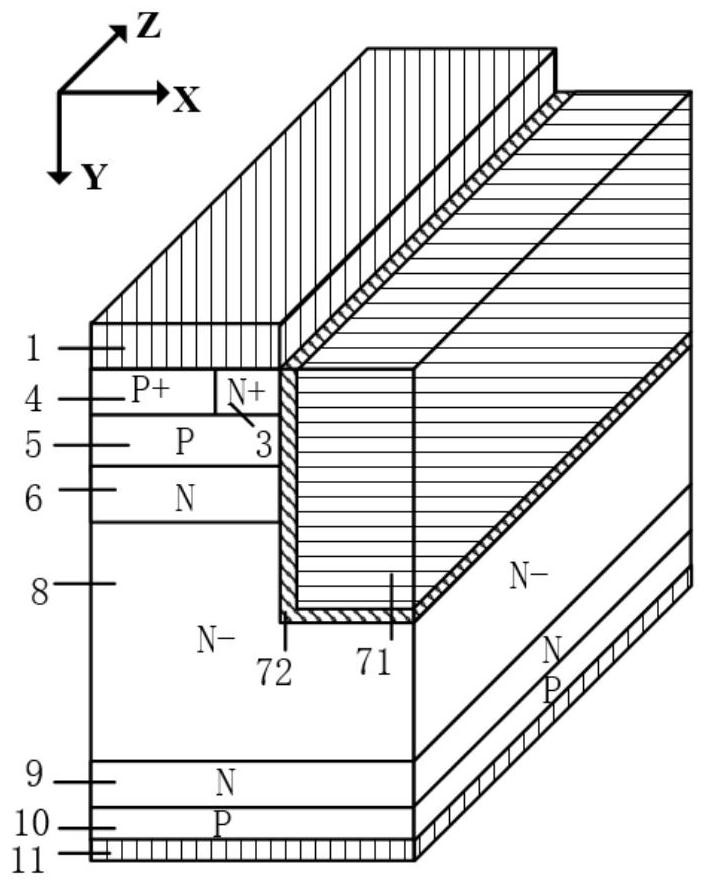

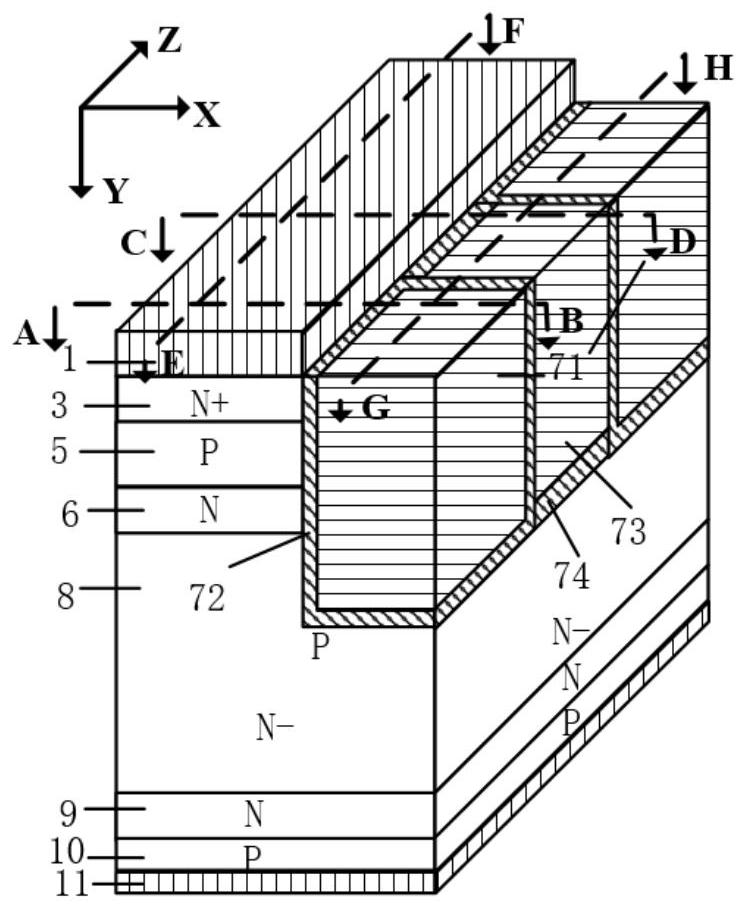

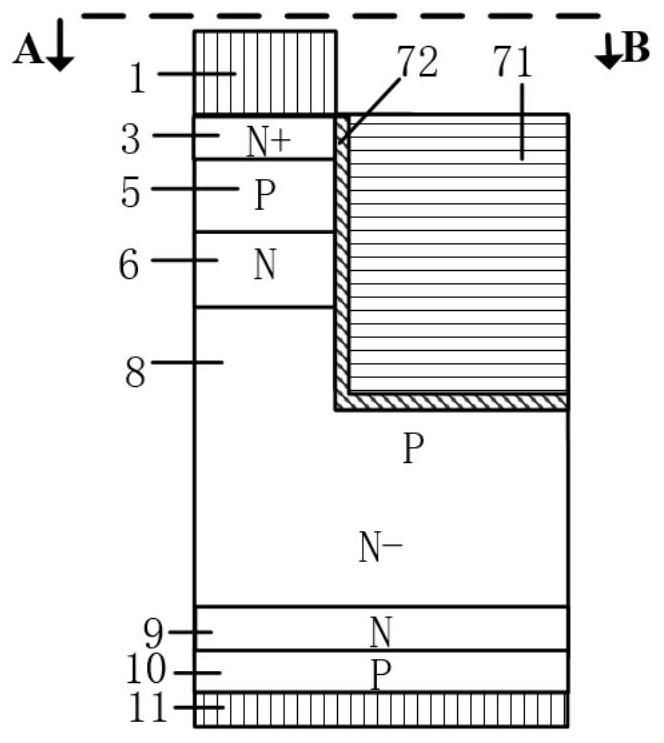

[0084] A three-dimensional trench gate charge storage type IGBT provided by the present invention defines the three-dimensional direction of the device with a three-dimensional Cartesian coordinate system: the direction from the N+ emitter region 3 to the gate electrode 71 of the device is defined as the X-axis direction, and the direction from the P The direction of the type collector region 10 pointing to the collector metal 11 is the Y-axis direction, and the direction perpendicular to the X-axis and Y-axis is the Z-axis direction;

[0085] Its semi-cellular structure and the cross-section along AB line, CD line, EF line and GH line are as follows figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 as shown,

[0086] It includes a collector metal 11, a P-type collector region 10, an N-type field stop layer 9, and an N-drift region 8 that are sequentially stacked from bottom to top along the Y-axis direction; a P-type buried layer 12 located above the N-drift regio...

Embodiment 2

[0091] A three-dimensional trench gate charge storage type IGBT provided in this embodiment defines the three-dimensional direction of the device in a three-dimensional Cartesian coordinate system: define the direction of the device from the N+ emitter region 3 to the gate electrode 71 as the X-axis direction, from The direction of the P-type collector region 10 pointing to the collector metal 11 is the Y-axis direction, and the direction perpendicular to the X-axis and Y-axis is the Z-axis direction;

[0092] Its semi-cellular structure and the section along the AB line, CD line, EF line, GH line and IJ line are as follows Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 as shown,

[0093] It includes a back collector metal 11, a P-type collector region 10, an N-type field stop layer 9, and an N-drift region 8 that are stacked sequentially from bottom to top along the Y-axis direction; Layer 12, the P-type buried layer 12 is discontinuous along...

Embodiment 3

[0098] A three-dimensional trench gate charge storage type IGBT provided by the present invention defines the three-dimensional direction of the device with a three-dimensional Cartesian coordinate system: the direction from the N+ emitter region 3 to the gate electrode 71 of the device is defined as the X-axis direction, and the direction from the P The direction of the type collector region 10 pointing to the collector metal 11 is the Y-axis direction, and the direction perpendicular to the X-axis and Y-axis is the Z-axis direction;

[0099] Its semi-cellular structure and the cross-section along AB line, CD line, EF line and GH line are as follows Figure 13 , Figure 14 , Figure 15 , Figure 16 and Figure 17 as shown,

[0100]Including back collector metal 11, P-type collector region 10, N-type field stop layer 9, N-drift region 8 stacked sequentially from bottom to top along the Y-axis direction; P-type buried layer located above N-drift region 8 12. The P-type bur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com