Conveying and machining system based on AGV

A processing system and processing area technology, applied in conveyors, conveyor objects, mechanical conveyors, etc., can solve problems such as reducing production line production flexibility, increasing equipment input costs, saving tooling and robotic arms, and improving equipment utilization. efficiency, saving the effect of control system software and hardware

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Features such as component models, material names, and connection structures that are not clearly stated in this technical solution are regarded as common technical features disclosed in the prior art.

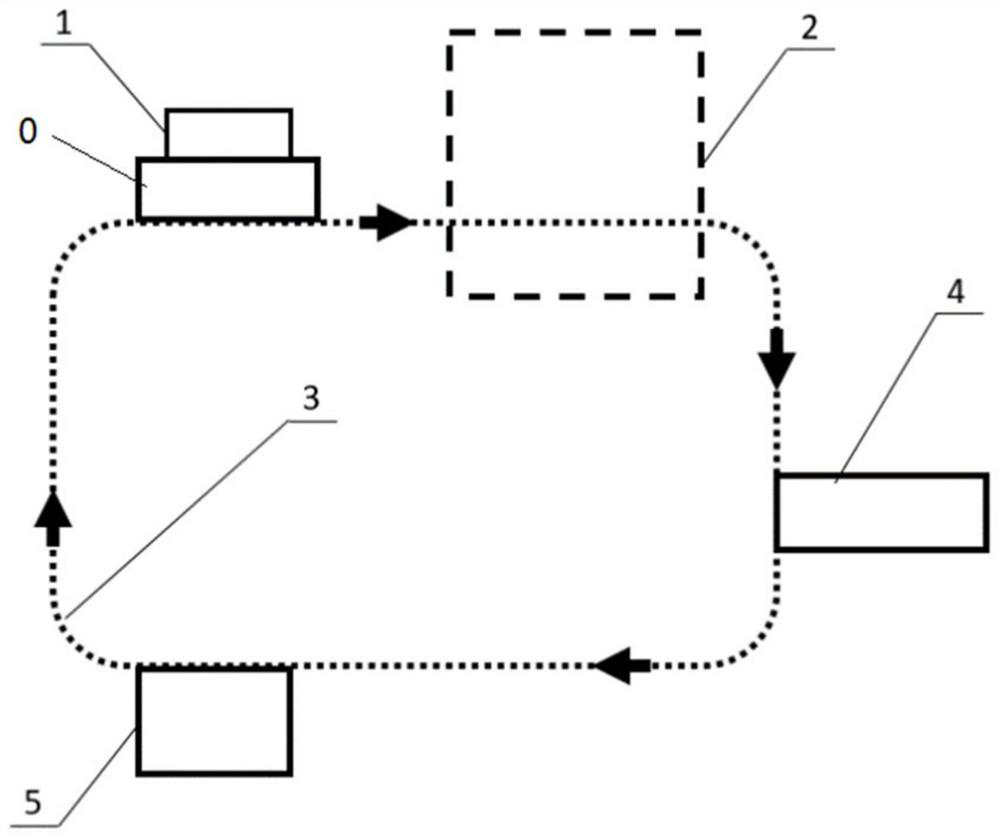

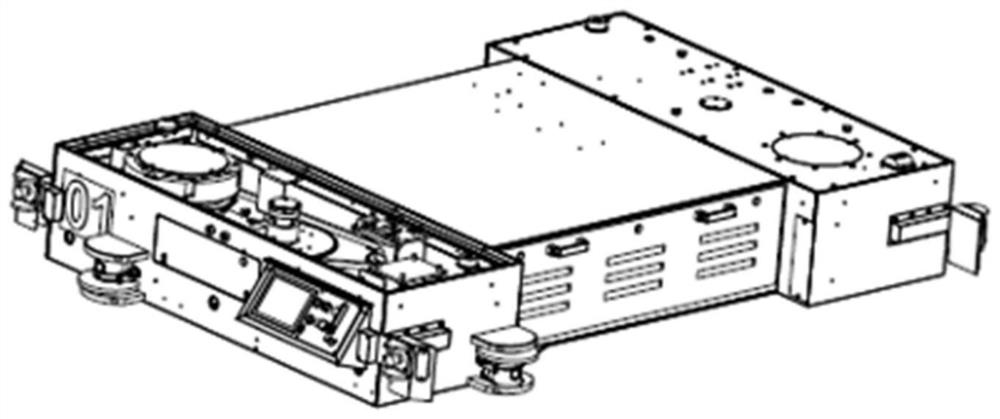

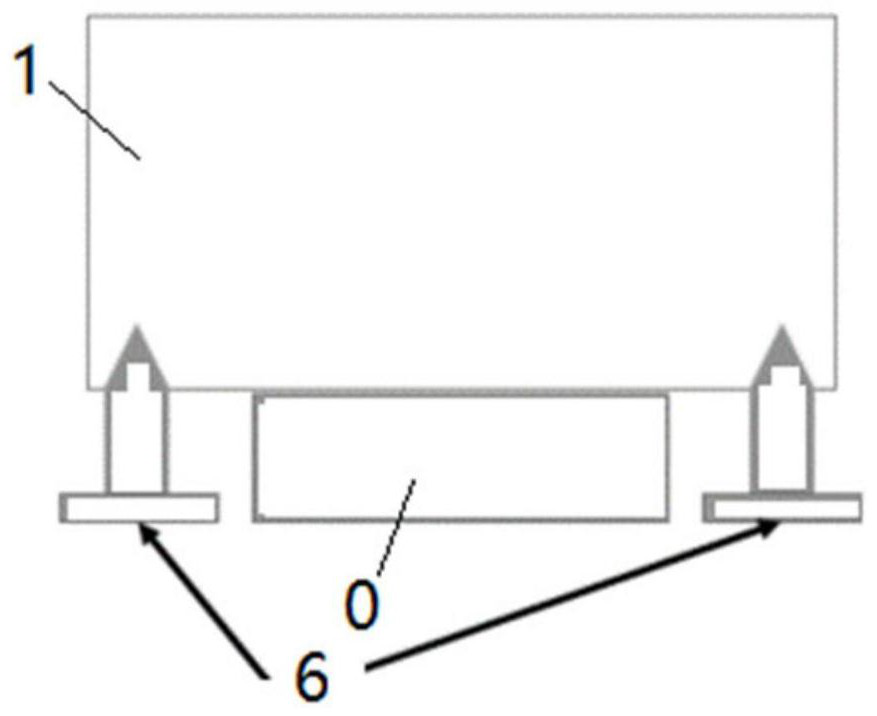

[0032] The AGV-based conveying and processing system in the present invention includes: AGV circulation route 3, AGV body 0, multiple process stations 2, tooling 1, wherein specifically refer to Figure 1 to Figure 4 .

[0033] In this embodiment, the tooling is integrated on the AGV body through a fine positioning structure, so that the AGV can carry the tooling and parts between stations. At the station with low precision requirements, the AGV’s own running accuracy can be used to meet the process requirements. The current technology can reach ±5mm; at the station with high precision requirements, corresponding mechanical mechanisms can be a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com