Preparation method of nicotine salt atomizer with small irritation

A technology of nicotine salt and atomizer, which is applied in the field of preparation of nicotine salt atomizer, can solve problems such as insufficient stability and uniformity of resistance value of heating circuit, rough surface of porous ceramic body, poor adhesion of heating element, etc., to achieve Good heat insulation effect, improved heat conduction ability, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

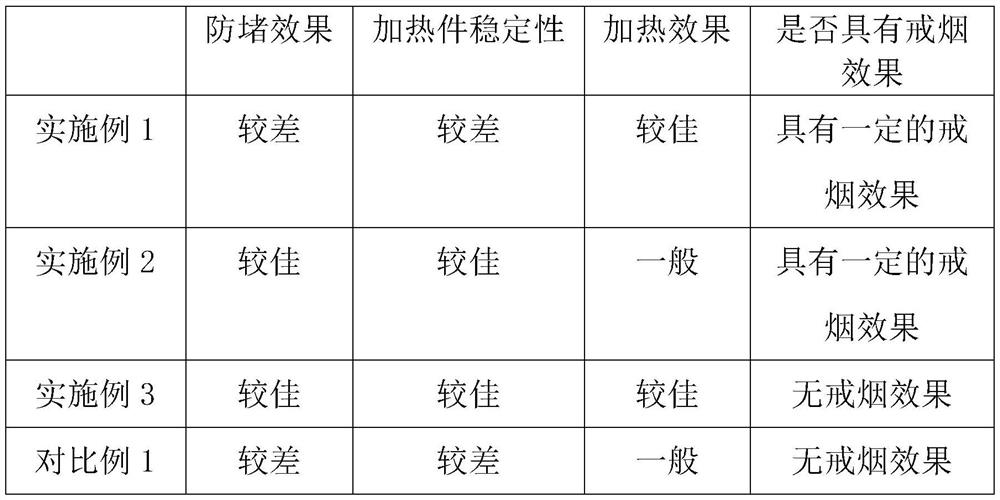

Examples

Embodiment 1

[0021] A preparation method of a nicotine salt atomizer with little irritation, comprising the following steps:

[0022] S1. Weigh 35-55 parts of ceramic powder with hydroxyl group compound, 15-20 parts of diatomaceous earth and 25-35 parts of inorganic glass microspheres in parts by weight, and place them in a mixer for mixing After mixing evenly, weigh 25-45 parts of pore-forming agent and add to continue mixing. After the mixing is completed, the embryo body A is designed according to the shape. At the same time, 80-90 parts by weight of ceramic powder and 10-20 parts by weight of ceramic powder are weighed. A number of pore-forming agents are mixed to form the embryo body B according to the shape design, and the obtained embryo body A and embryo body B are superposed together, and the heating element is inserted into the side of the embryo body B away from the embryo body A, and then placed High-temperature firing is carried out in a high-temperature sintering device to fo...

Embodiment 2

[0034] A preparation method of a nicotine salt atomizer with little irritation, comprising the following steps:

[0035] S1. Weigh 35-55 parts of ceramic powder with hydroxyl group compound, 15-20 parts of diatomaceous earth and 25-35 parts of inorganic glass microspheres in parts by weight, and place them in a mixer for mixing After mixing evenly, weigh 25-45 parts of pore-forming agent and add to continue mixing. After the mixing is completed, the embryo body A is designed according to the shape. At the same time, 80-90 parts by weight of ceramic powder and 10-20 parts by weight of ceramic powder are weighed. A number of pore-forming agents are mixed to form the embryo body B according to the shape design, and the obtained embryo body A and embryo body B are superposed together, and the heating element is inserted into the side of the embryo body B away from the embryo body A, and then placed High-temperature firing is carried out in a high-temperature sintering device to fo...

Embodiment 3

[0047] A preparation method of a nicotine salt atomizer with little irritation, comprising the following steps:

[0048] S1. Weigh 35-55 parts of ceramic powder with hydroxyl group compound, 15-20 parts of diatomaceous earth and 25-35 parts of inorganic glass microspheres in parts by weight, and place them in a mixer for mixing After mixing evenly, weigh 25-45 parts of pore-forming agent and add to continue mixing. After the mixing is completed, the embryo body A is designed according to the shape. At the same time, 80-90 parts by weight of ceramic powder and 10-20 parts by weight of ceramic powder are weighed. A number of pore-forming agents are mixed to form the embryo body B according to the shape design, and the obtained embryo body A and embryo body B are superposed together, and the heating element is inserted into the side of the embryo body B away from the embryo body A, and then placed High-temperature firing is carried out in a high-temperature sintering device to fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com